Biological treatment method of high-ammonia nitrogen pig raising biogas slurry

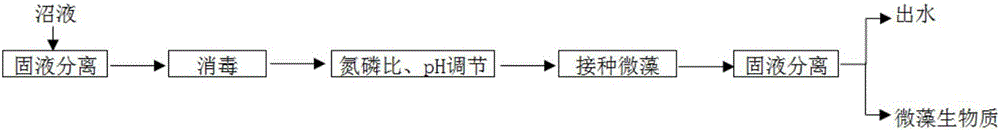

A high-ammonia-nitrogen pig biogas treatment technology, applied in the field of biological environmental protection, can solve the problems of difficult operation, high cost of high-ammonia nitrogen biogas slurry treatment, poor effect, etc., and achieve the effect of low cost, improved environment and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] (1) After solid-liquid separation of 10L swine biogas slurry, the clear liquid was sterilized by adding 2ml of 10% sodium hypochlorite solution. The measured initial ammonia nitrogen concentration was 190.3mg / L, total phosphorus concentration was 6.3mg / L, and pH was 8.8. The ratio of nitrogen to phosphorus and pH are all within the appropriate range and can be used directly.

[0019] (2) Inoculate the microalgae in the logarithmic phase into the pretreated biogas slurry according to the inoculation amount of 10% of the volume ratio of the microalgae and the biogas slurry. At a temperature of 25°C, a light intensity of 5000lux, a light-to-dark ratio of 12:12h, and aeration and stirring for 10 days, the removal rate of ammonia nitrogen reached 99.6%, and the removal rate of total phosphorus reached 93.1%.

[0020] (3) After the treatment is completed, the biogas slurry containing the microalgal pulp is separated from solid to liquid by the flocculation sedimentation metho...

Embodiment 2

[0022] (1) After solid-liquid separation of 10L swine biogas slurry, the clear liquid was sterilized by adding 2ml of 10% sodium hypochlorite solution. The measured initial ammonia nitrogen concentration was 249.4mg / L, total phosphorus concentration was 8.5mg / L, and pH was 8.2. The ratio of nitrogen to phosphorus and pH are all within the appropriate range and can be used directly.

[0023] (2) Inoculate the microalgae in the logarithmic phase into the pretreated biogas slurry according to the inoculation amount of 10% of the volume ratio of the microalgae and the biogas slurry. At a temperature of 25°C, a light intensity of 5000lux, a light-to-dark ratio of 12:12h, and aeration and stirring for 10 days, the removal rate of ammonia nitrogen reached 95.9%, and the removal rate of total phosphorus reached 90.1%.

[0024] (3) After the treatment is completed, the biogas slurry containing the microalgae pulp is separated from solid to liquid by the flocculation sedimentation metho...

Embodiment 3

[0026] (1) After solid-liquid separation of 10L swine biogas slurry, the clear liquid was sterilized by adding 2ml of 10% sodium hypochlorite solution. The measured initial ammonia nitrogen concentration was 318.9mg / L, total phosphorus concentration was 10.8mg / L, and pH was 8.4. The ratio of nitrogen to phosphorus and pH are all within the appropriate range and can be used directly.

[0027] (2) Inoculate the microalgae in the logarithmic phase into the pretreated biogas slurry according to the inoculation amount of 10% of the volume ratio of the microalgae and the biogas slurry. At a temperature of 25°C, a light intensity of 5000lux, a light-to-dark ratio of 12:12h, and aeration and stirring for 10 days, the removal rate of ammonia nitrogen reached 89.7%, and the removal rate of total phosphorus reached 91.2%.

[0028] (3) After the treatment is completed, the solid-liquid separation of the biogas slurry containing the microalgae pulp is carried out by the flocculation sedime...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dry weight | aaaaa | aaaaa |

| Dry weight | aaaaa | aaaaa |

| Dry weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com