Foam heat-insulating brick for roof

A technology of foam insulation and foam layer is applied in the field of building bricks, which can solve the problems of poor waterproof, low strength of insulation layer, difficult and cumbersome construction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

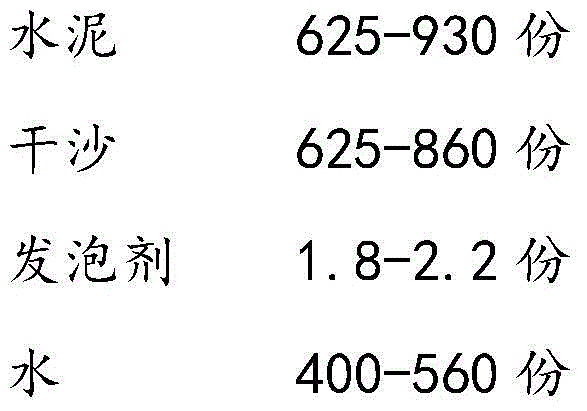

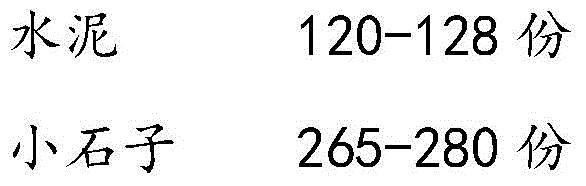

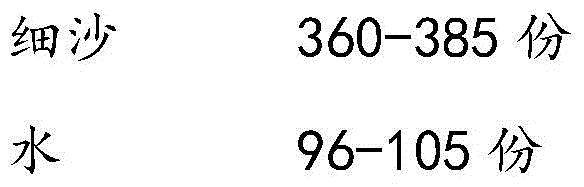

[0030] A roof foam heat insulation brick, which has a foam layer combined with a surface layer; wherein, the component weight ratio of the foam layer is as follows: 625 parts of cement, 625 parts of dry sand, 1.8 parts of foaming agent, water 400 parts; when making, first fully mix the water of 625 parts by weight of cement, the dry sand of 625 parts by weight and the water of 275 parts by weight; then mix the foaming agent of 1.8 parts by weight with the water of 125 parts by weight and fully foam, After it is completely and fully foamed, add the well-mixed cement, dry sand and water, and finally fully mix together and complete foaming. The component weight ratio of the surface layer is as follows: 120 parts of cement, 265 parts of pebbles, 360 parts of fine sand, and 96 parts of water.

Embodiment 2

[0032] A roof foam heat insulation brick, which has a layer-bonded foam layer and a surface layer; wherein, the component weight ratio of the foam layer is as follows: 930 parts of cement, 610 parts of dry sand, 2.2 parts of foaming agent, slag A total of 250 parts with ceramsite, 560 parts of water; when making, first fully mix 930 parts by weight of cement, 610 parts by weight of dry sand, 250 parts by weight of slag and ceramsite, and 395 parts by weight of water; then mix 2.2 The foaming agent is mixed with 165 parts by weight of water and fully foamed. After it is completely and fully foamed, the fully mixed cement, dry sand and water are added, and finally fully mixed together and completely foamed. Can. The component weight ratio of the surface layer is as follows: 128 parts of cement, 280 parts of pebbles, 385 parts of fine sand, and 105 parts of water.

Embodiment 3

[0034] A roof foam heat insulation brick, which has a foam layer and a surface layer combined by layers; wherein, the component weight ratio of the foam layer is as follows: 800 parts of cement, 580 parts of dry sand, 2.0 parts of foaming agent, slag , and fly ash are 220 parts altogether, and water 500 parts; When making, earlier the cement of 800 parts by weight, the dry sand of 580 parts by weight, the slag of 220 parts by weight and fly ash, and the water of 350 parts by weight are fully mixed; Afterwards, 2.0 parts by weight of foaming agent and 150 parts by weight of water are mixed and fully foamed, then fully mixed cement, dry sand and water are added, and finally fully mixed together and completely foamed. The component weight ratio of the surface layer is as follows: 125 parts of cement, 270 parts of pebbles, 375 parts of fine sand, 96 parts of foam layer components, and 100 parts of water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com