A kind of bean qingru porcelain and preparation method thereof

A technology of bean green rut and green body, which is applied in the field of bean green rut porcelain and its preparation technology, can solve the problems of ru porcelain loss and difficult restoration, and achieve the effects of short preparation period, reduced loss on ignition rate, strong photocatalysis and antibacterial performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

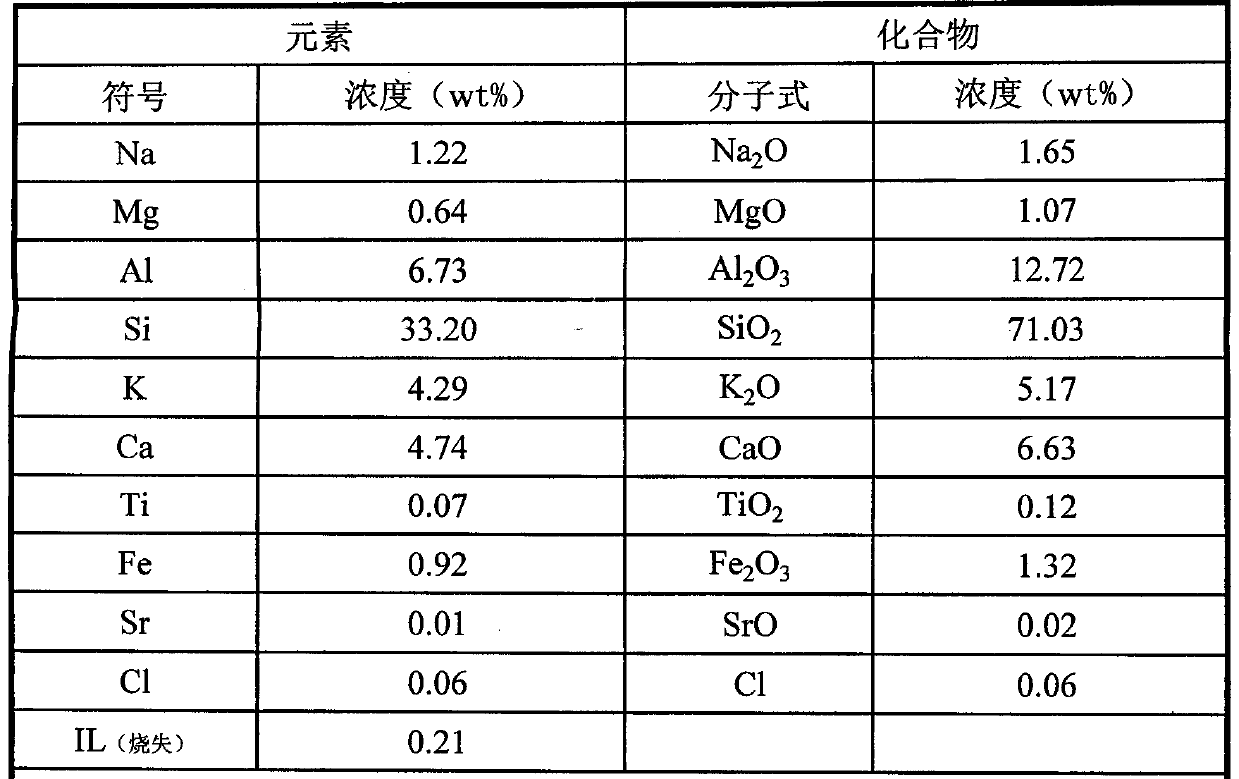

Image

Examples

preparation example Construction

[0030] Its preparation method comprises the following steps:

[0031] Step 1. According to the above weight percentage, take the green body raw materials clay, wind cave soil, medical stone and purple wood knot successively, and mix uniformly to obtain a dry material. After that, add 0.35 to 0.4 times the quality of water to the obtained dry material, Stir evenly and send it to a ball mill, and ball mill it into a slurry with a particle size of 100-150 mesh to make tire material;

[0032] Step 2. Pass the tire material obtained in step 1 through a 80-120 mesh sieve first, then perform iron removal treatment, then perform water filtration and mud refining, and use the refined mud to manually pull the blank to form a green body. And place the green body at room temperature to dry in the shade for 4-6 days, after that, put it into a kiln for bisque firing and set aside;

[0033] Step 3. According to the above weight percentage, take the glaze raw materials feldspar, soda stone, ...

Embodiment 1

[0047] A Douqingru porcelain, comprising a green body and glaze, the green body is composed of the following raw materials in weight percentage: clay 55%, Fengxun soil 25%, medical stone 15%, purple wood knot 5%; the glaze The percentage by weight of each raw material in is: feldspar 45%, soda stone 13%, calcite 12%, black ruby 18%, agate stone 12%;

[0048] The mass percentage of titanium dioxide in the clay is 1.08%, and the mass percentage of aluminum oxide is 26.08%.

[0049] Its preparation method comprises the following steps:

[0050] Step 1. According to the above weight percentage, take the green body raw materials clay, wind cave soil, medical stone and purple wood knot successively, and mix them uniformly to obtain a dry material. After that, add water 0.35 times its mass to the obtained dry material, and stir evenly Afterwards, it is sent into a ball mill, and the ball is milled into a slurry with a particle size of 150 meshes to make tire material;

[0051] St...

Embodiment 2

[0058] A Douqingru porcelain, comprising a green body and glaze, the green body is composed of the following raw materials in weight percentage: clay 65%, Fengxun soil 15%, medical stone 15%, purple wood knot 5%; the glaze The percentage by weight of each raw material in is: feldspar 55%, soda stone 7%, calcite 6%, black ruby 12%, agate stone 20%;

[0059] The mass percentage of titanium dioxide in the clay is 1.09%, and the mass percentage of aluminum oxide is 26.12%.

[0060] Its preparation method comprises the following steps:

[0061] Step 1. According to the above weight percentage, take the green body raw materials clay, wind cave soil, medical stone and purple wood knot in sequence, and mix them uniformly to obtain a dry material. After that, add water 0.4 times its mass to the obtained dry material, and stir evenly Afterwards, it is sent into a ball mill, and the ball is milled into a slurry with a particle size of 100 mesh to make tire material;

[0062] Step 2: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com