Synthesis method of m-nitrobenzaldehyde

A technology of nitrobenzaldehyde and a synthesis method, which is applied in the synthesis field of m-nitrobenzaldehyde, can solve the problems of long process steps, large environmental pollution and high production cost, and achieves low cost of raw materials, simplified steps and short production cycle. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A method for synthesizing m-nitrobenzaldehyde, the raw materials and instruments used are shown in Table 1.

[0027] Table 1 Statistics of raw materials and instruments

[0028] Raw materials\parameters

Manufacturer

Specification

Content

Unlimited

Second grade

≥99.5%

Unlimited

Second grade

≥99.0%

Unlimited

Qualified product

≥99.0%

Reaction device

Unlimited

Three-necked flask

-

[0029] The synthesis of m-nitrobenzaldehyde in this embodiment specifically includes the following steps:

[0030] Step 1: Reaction, specifically: add 19.70 grams (0.105mol) of copper nitrate into the reaction device, slowly add 50 grams (2.78mol) of water at room temperature to completely dissolve the copper nitrate to obtain a copper nitrate solution (here, add water The rate is adjustable, and the purpose is to achieve complete dissolution of copper nitrate); add 0.017 grams (0.000101mol) of silver nitrate to the copper nitrate s...

Embodiment 2- Embodiment 6

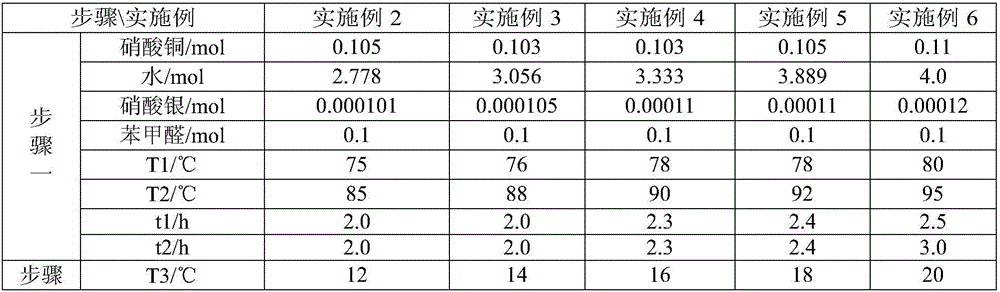

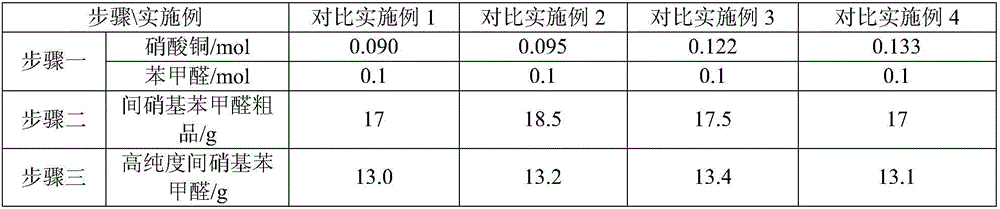

[0045] Example 2-Example 6 differs from Example 1 in Table 2.

[0046] Table 2 Example 2-Example 6 Parameter Statistics Table

[0047]

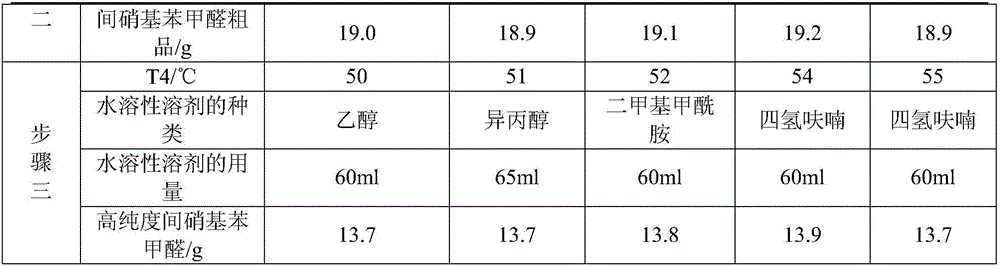

[0048]

[0049] Example 2-The high-purity m-nitrobenzaldehyde obtained in Example 6 adopts the same chromatographic detection method as that of Example 1, and the results are shown in Table 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com