Synthesizing method for gamma-pyrone compound

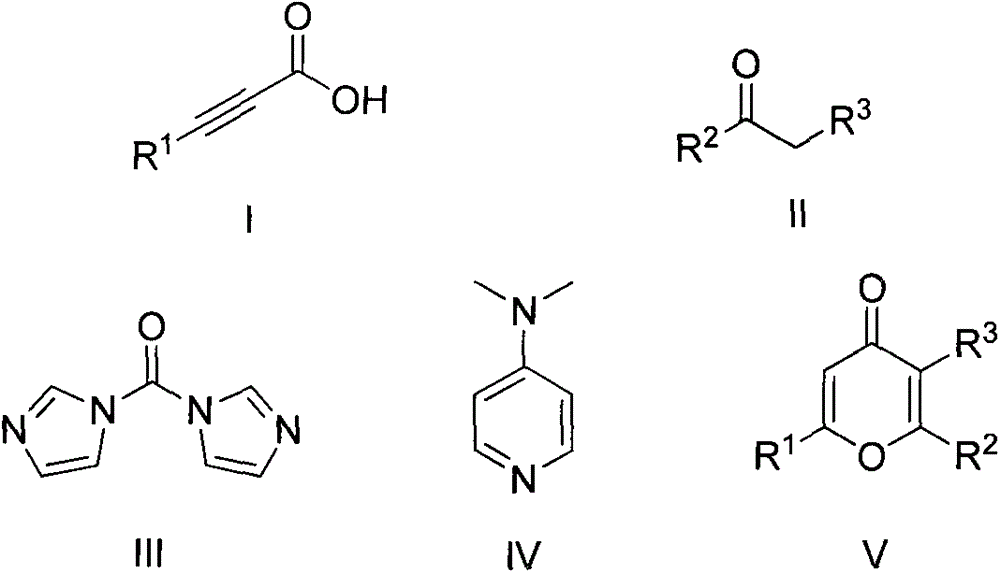

A technology for pyrone and compound, which is applied in the field of organic chemistry synthesis methodology, and can solve the problems of narrow application range of substrates, difficult availability of raw materials and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

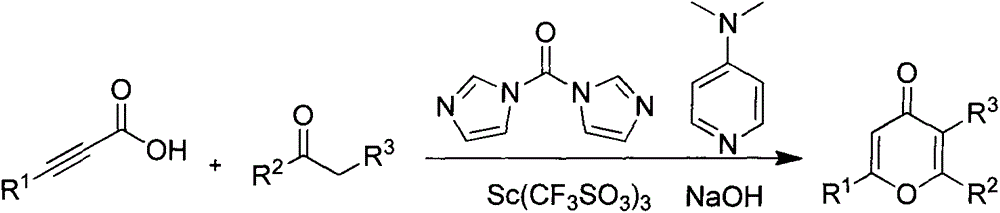

Method used

Image

Examples

Embodiment 1

[0011] Example 1: Reaction of 3-phenylpropiolic acid and ethyl acetoacetate

[0012] 51 mg (0.35 mmol) of 3-phenylpropiolic acid, 91 mg (0.7 mmol) of ethyl acetoacetate, 85 mg (0.525 mmol) of N, N'-carbonyldiimidazole shown in formula III, and 4 -Dimethylaminopyridine 47mg (0.385mmol), sodium hydroxide 28mg (0.7mmol), scandium trifluoromethanesulfonate 30mg (0.07mmol) and 1,2-dichloroethane 2mL were placed in a 25mL two-necked bottle, at 80 Reaction at ℃ for 5-6h, cooling and concentrating the reaction liquid, eluting with a mixed solvent of petroleum ether: ethyl acetate ratio of 5:1 as eluent column chromatography, collecting the eluate of all detected products 58 mg of the product was obtained after the solvent was removed by rotary evaporation, and the yield was 65%.

[0013] Whitesolid, mp: 105-106°C. 1 HNMR (300MHz, CDCl 3 ): δ7.74(d, J=6.3Hz, 2H), 7.44-7.54(m, 3H), 6.77(s, 1H), 4.40(q, J=6.9Hz, 2H), 2.49(s, 3H) , 1.38(t, J=6.9Hz, 3H). 13 CNMR (75MHz, CDCl 3 ): δ17...

Embodiment 2

[0014] Example 2: Reaction of 3-phenylpropiolic acid and methyl acetoacetate

[0015] 51 mg (0.35 mmol) of 3-phenylpropiolic acid, 81 mg (0.7 mmol) of methyl acetoacetate, 85 mg (0.525 mmol) of N, N'-carbonyldiimidazole shown in formula III, and 4 -Dimethylaminopyridine 47mg (0.385mmol), sodium hydroxide 28mg (0.7mmol), scandium trifluoromethanesulfonate 30mg (0.07mmol) and 1,2-dichloroethane 2mL were placed in a 25mL two-necked bottle, at 80 Reaction at ℃ for 5-6h, cooling and concentrating the reaction liquid, eluting with a mixed solvent of petroleum ether: ethyl acetate ratio of 5:1 as eluent column chromatography, collecting the eluate of all detected products Partially, 47 mg of the product was obtained after the solvent was removed by rotary evaporation, and the yield was 51%.

[0016] Whitesolid, mp: 130-131°C. 1 HNMR (500MHz, CDCl 3 ): δ7.75(d, J=6.7Hz, 2H), 7.47-7.54(m, 3H), 6.81(s, 1H), 3.93(s, 3H), 2.51(s, 3H). 13 CNMR (75MHz, CDCl 3 ): δ175.8, 166.2, 165.1, 1...

Embodiment 3

[0017] Example 3: Reaction of 3-phenylpropiolic acid and tert-butyl acetoacetate

[0018] 51 mg (0.35 mmol) of 3-phenylpropiolic acid, 111 mg (0.7 mmol) of tert-butyl acetoacetate, 85 mg (0.525 mmol) of N, N'-carbonyldiimidazole shown in formula III, and 85 mg (0.525 mmol) of N, N'-carbonyldiimidazole shown in formula IV 47mg (0.385mmol) of 4-dimethylaminopyridine, 28mg (0.7mmol) of sodium hydroxide, 30mg (0.07mmol) of scandium trifluoromethanesulfonate and 2mL of 1,2-dichloroethane were placed in a 25mL two-necked bottle, and React at 80°C for 5-6h, cool and concentrate the reaction solution, and elute through column chromatography using a mixed solvent of petroleum ether: ethyl acetate at a ratio of 5:1 as the eluent, and collect all the eluted products detected. The liquid part was evaporated to remove the solvent to obtain 40mg of the product with a yield of 41%.

[0019] Whitesolid, mp: 145-146°C. 1 HNMR (300MHz, CDCl 3 ): δ7.71-7.74(m, 2H), 7.42-7.51(m, 3H), 6.72(s, 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com