Preparation method of adsorbent for refining trimesic acid

A technology for trimesic acid and an adsorbent, which is applied in the field of preparation of refined trimesic acid adsorbents, can solve problems such as inability to obtain high-purity trimesic acid, and achieves improved corrosion resistance, improved service life, and reduced resin breakage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

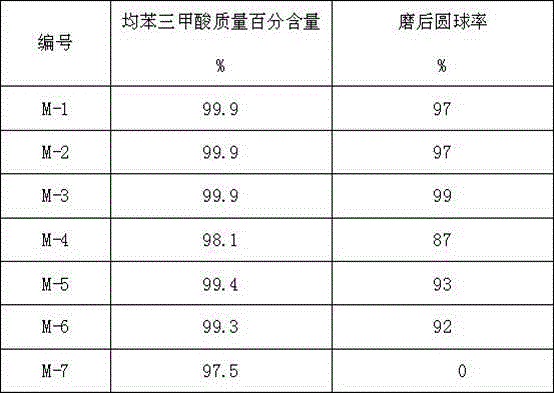

Embodiment 1

[0016] In a 2000L reactor, add 100Kg of styrene, 12Kg of triallyl cyanurate, 0.2Kg of p-fluorocinnamaldehyde, and 0.2Kg of 1-allyl-3-methylimidazole tetrafluoroborate , 1Kg of 4-hydroxynonenal as a comonomer, 0.02Kg of phenylethyl dithiobenzoate, 2Kg (1,1,4,4-tetramethyl-2-butyne-1,4- Di-tert-butyl peroxide, 30Kg of liquid wax, reacted at 90° C. for 11 hours to form polymerized white balls, filtered and dried, and extracted the liquid wax with gasoline to obtain a trimesic acid adsorbent. Numbered M-1.

Embodiment 2

[0018] In a 2000L reactor, add 100Kg of styrene, 5Kg of triallyl cyanurate, 0.05Kg of p-fluorocinnamaldehyde, and 0.05Kg of 1-allyl-3-methylimidazole tetrafluoroborate , 0.5Kg of 4-hydroxynonenal as a comonomer, 0.01Kg of phenylethyl dithiobenzoate, 1Kg (1,1,4,4-tetramethyl-2-butyne-1,4 -diyl)di-tert-butyl peroxide, 20Kg of white oil, reacted at 80°C for 5h to generate polymerized white balls, filtered and dried, and extracted the white oil with gasoline to obtain a trimesic acid adsorbent. Numbered M-2.

Embodiment 3

[0020] In a 2000L reactor, add 100Kg of styrene, 20Kg of triallyl cyanurate, 0.5Kg of p-fluorocinnamaldehyde, and 0.5Kg of 1-allyl-3-methylimidazole tetrafluoroborate , 2Kg of 4-hydroxynonenal as a comonomer, 0.05Kg of phenylethyl dithiobenzoate, 4Kg (1,1,4,4-tetramethyl-2-butyne-1,4- Di-tert-butyl peroxide, 60Kg of liquid wax, reacted at 95°C for 15 hours to form polymerized white balls, filtered, dried, and extracted the liquid wax with gasoline to obtain trimesic acid adsorbent, No. for M-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com