Patents

Literature

43 results about "1-allyl-3-methylimidazolium" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of grafted cellulose medicinal molecule with pH/temperature responsiveness

InactiveCN104558421AShort processSimple processPharmaceutical non-active ingredientsBulk chemical productionFunctional monomerAtom-transfer radical-polymerization

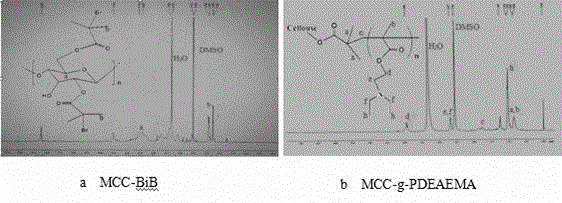

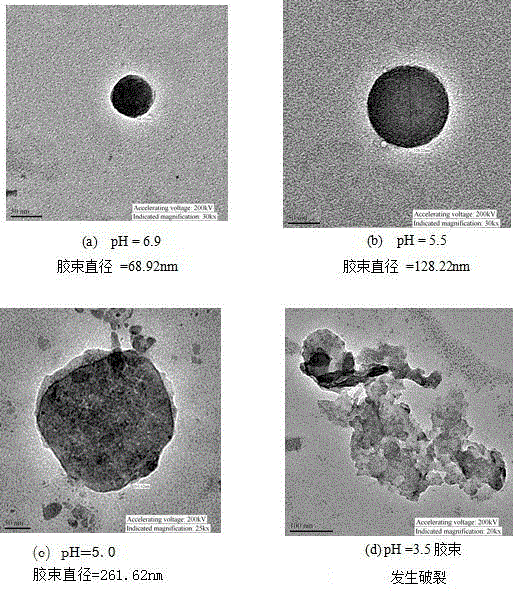

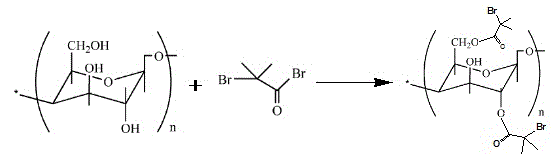

The invention belongs to the field of high polymer materials and biomedical engineering, and particularly relates to a method for preparing a grafted cellulose medicinal molecule with pH / temperature responsiveness by modifying cellulose raw materials via an atom transfer radical polymerization (ATRP) technology in an ionic liquid homogeneous system. The method comprises the following steps: by taking ionic liquid as a solvent and taking microcrystalline cellulose as a raw material, dissolving the microcrystalline cellulose in the ionic liquid 1-allyl-3-methylimidazolium chloride ([AMIM] C1); preparing a macroinitiator MCC-BiB by 2-bromopropionyl bromide; importing a micromolecular alcohol cosolvent to ensure that a homogeneous reaction system is formed by a pH / temperature sensitive monomer and the ionic liquid; grafting the functional monomer onto the microcrystalline cellulose by utilizing an ATRP method to form a grafted cellulose molecular brush, wherein the grafting efficiency can be up to 80%, the reaction is controllable and the molecular weight distribution is 1.25. The prepared cellulose grafted copolymer can be self-assembled into spherical micelle in DME, has certain pH and temperature sensitivity and can be used as a drug sustained release carrier.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Nanometer antibacterial mothproof cashmere composite fiber and manufacturing method thereof

InactiveCN104911737AExcellent long-lasting antibacterial and anti-moth performanceAvoid breedingConjugated cellulose/protein artificial filamentsConjugated synthetic polymer artificial filamentsCocamidopropyl betaineSheep wool

The invention discloses a nanometer antibacterial mothproof cashmere composite fiber. The nanometer antibacterial mothproof cashmere composite fiber is prepared from 24-30 parts by weight of Xizang cashmere, 22-28 parts by weight of sheep wool, 7-9 parts by weight of polyamide fibers, 12-15 parts by weight of mulberry silk, 15-18 parts by weight of Jutecell, 18-22 parts by weight of modal fibers, 10-13 parts by weight of starch maize, 5-7 parts by weight of paraffin, 1.3-2.5 parts by weight of cocamidopropyl betaine, 11-13 parts by weight of butyl acrylate, 2-3 parts by weight of nanometer zinc oxide, 3-5 parts by weight of mint extract, 1-3 parts by weight of cocklebur fruit, 2-4 parts by weight of Angelica sylvestris, 100-110 parts by weight of 1-ethyl-3-methylimidazolium acetate, 90-100 parts by weight of 1-allyl-3-methylimidazolium chloride, 21-25 parts by weight of an assistant and a proper amount of water. Through optimization of formula and the preparation technology, the treated cashmere composite fibers have excellent and lasting antibacterial and mothproof performances, can effectively inhibit bacteria growing in cloth wear, can remove a peculiar smell, have no irritation, has safety, health and heath care effects, and can be used for making cashmere sweater suitable for people of all ages.

Owner:TONGLING HONGZHENG NETWORK SCI & TECH CO LTD

Polyurethane composite material with high flame retardance, heat resistance and water resistance

The invention discloses a polyurethane composite material with the high flame retardance, heat resistance and water resistance.The polyurethane composite material is prepared from polyurethane rubber, chloroprene rubber, methyl phenyl vinyl silicone rubber, stearic acid, zinc oxide, sulfur, 2,5-dimethyl-2,5-di(tert-butylperoxy)hexane, a flame retardant, modified composite packing, a molecular sieve, silicon carbide, graphene, hexafluorobiphenol A, 1-allyl-3-methylimidazolium chloride, 2,2-bis(3-amino-4-hydroxyphenyl)hexafluoropropane, an accelerant DM, an accelerant M, an anti-aging agent MC and lanthanum oxide.The polyurethane composite material with the high flame retardance, heat resistance and water resistance is high in strength, excellent in heat resistance and water resistance, good in flame retardance and long in service life.

Owner:CHUZHOU GLOBAL POLYURETHANE TECH CO LTD

Nanometer far infrared ceramic fiber woven fabric and production method of nanometer far infrared ceramic fiber woven fabric

ActiveCN104593931AImprove heat insulation and flame retardant effectImprove wear resistanceConjugated cellulose/protein artificial filamentsWoven fabricsMethacrylateEpoxy

The invention discloses nanometer far infrared ceramic fiber woven fabric. The nanometer far infrared ceramic fiber woven fabric is formed by warp yarns and weft yarns in a woven mode through an air jet loom, and is characterized in that raw materials of the warp yarns and raw materials of the weft yarns comprise, by weight, 27 parts to 33 parts of syndiotactic polypropylene, 10 parts to 14 parts of linear low-density polyethylene, 8 parts to 10 parts of polyurethane films, 16 parts to 22 parts of epoxy resin, 0.4 part to 0.7 part of zinc nitrate, 0.6 part to 0.9 part of magnesium hydrate, 1 part to 3 parts of water glass, 20 parts to 25 parts of nylon yarns, 23 parts to 26 parts of colored cotton fibers, 18 parts to 23 parts of nanometer far infrared ceramic fibers, 21 parts to 24 parts of cellulose acetate fibers, 7 parts to 10 parts of isobutyl methacrylate, 5 parts to 9 parts of peach gum, 1 part to 3 parts of radix bupleuri, 2 parts to 5 parts of fossil fragments, 80 parts to 90 parts of 1-butyl-3-methylimidazolium acetate, 90 parts to 100 parts of 1-allyl-3-methylimidazolium chlorine salt, a proper amount of water and 4 parts to 8 parts of assistants. By means of the nanometer far infrared ceramic fiber woven fabric, the spinnability of plant fibers and the spinning quality are improved, the warmth keeping performance, the wearing resistance, the pilling resistance and the washing resistance of the woven fabric are further improved, and the market prospects are good.

Owner:JIXI YUANDAO AGRI IND TECH

Sol-gel ionic liquid solid phase microextraction extraction fiber and preparation method thereof

InactiveCN101920193AHigh precisionImprove accuracyIon-exchange process apparatusOther chemical processesGas phaseVapor phase chromatography

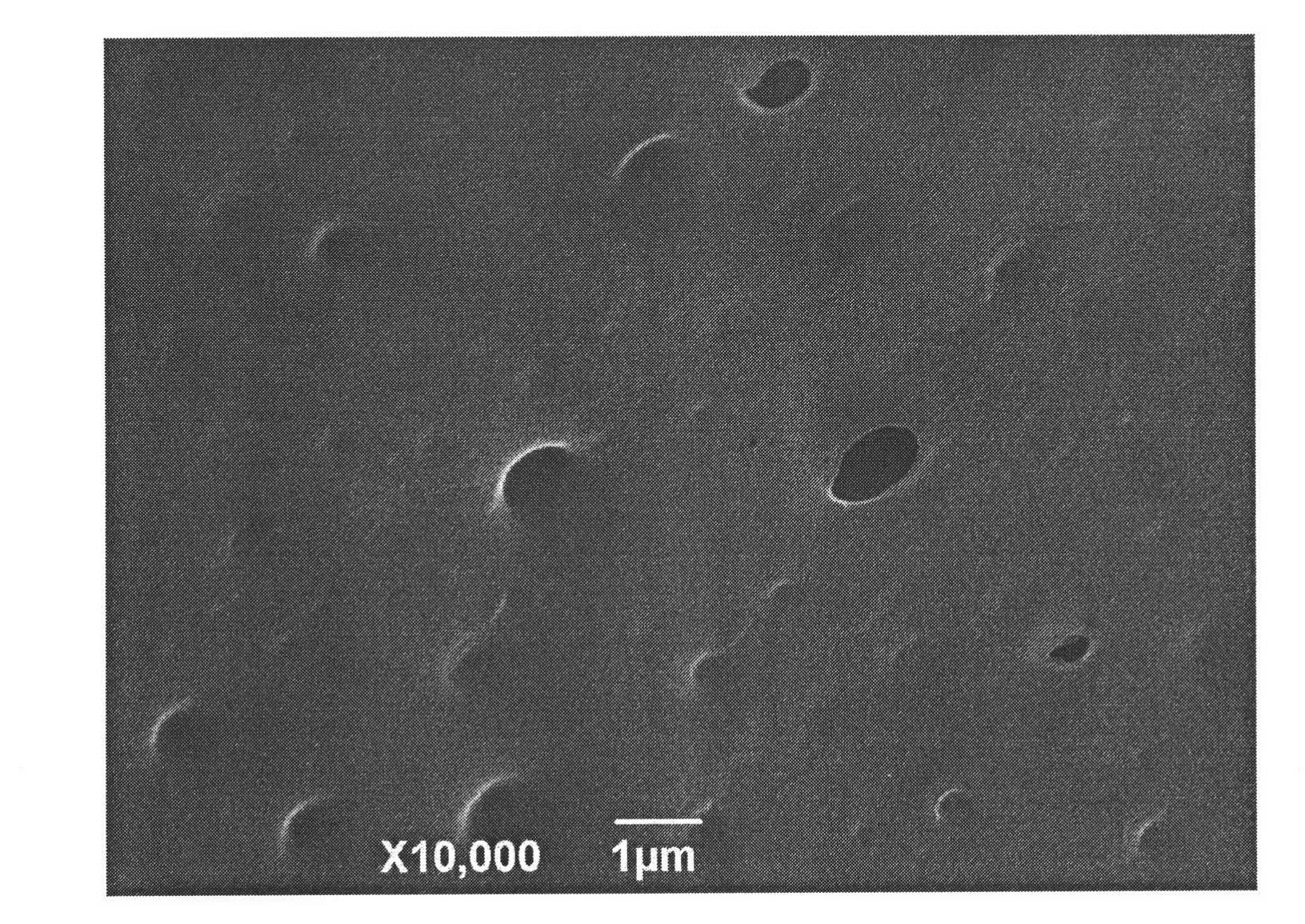

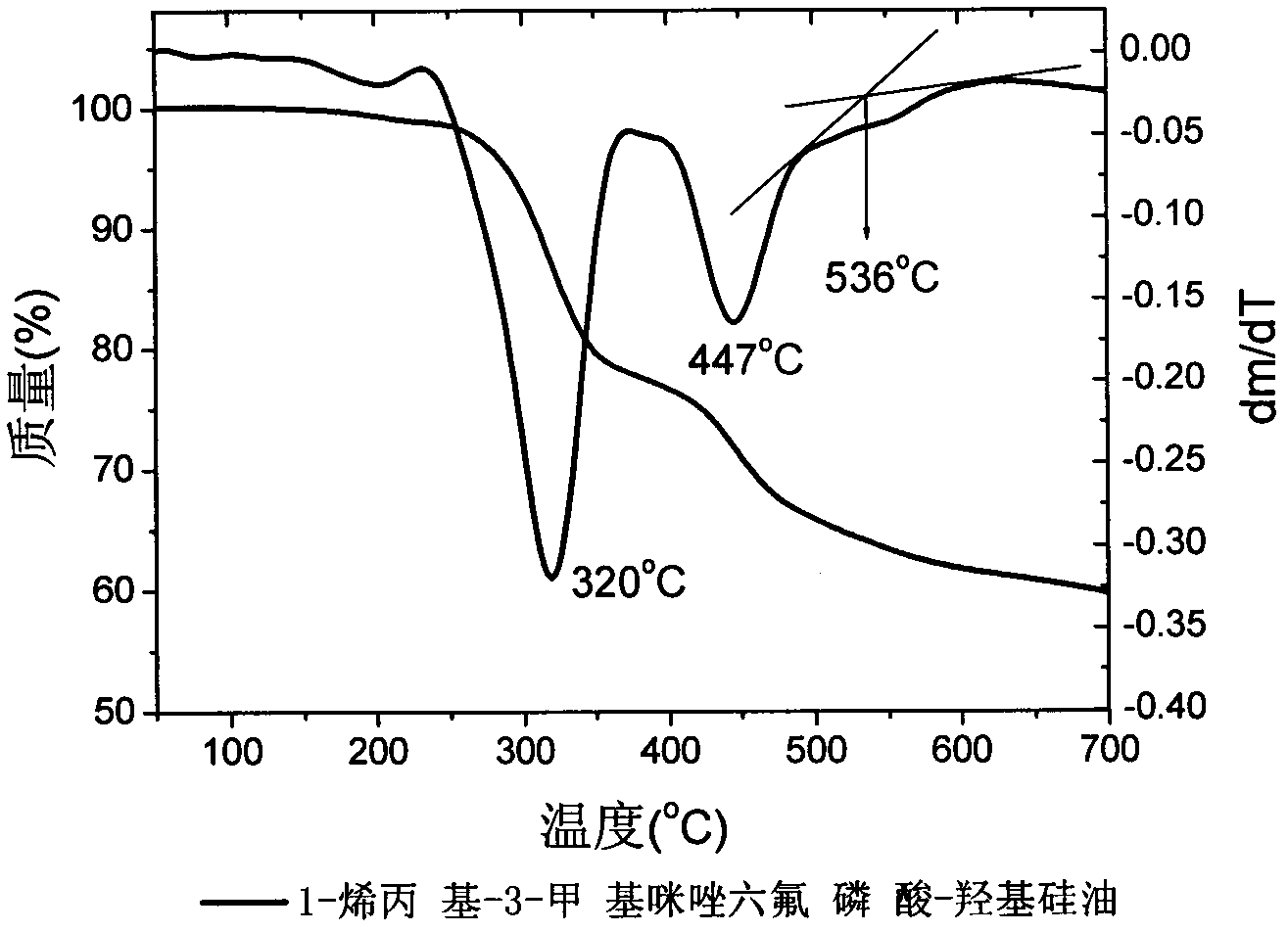

The invention belongs to the technical field of chemical analysis and test instruments, relates to the fields of polymer chemistry and analytical chemistry, and relates to a sol-gel ionic liquid solid phase microextraction extraction fiber and a preparation method thereof. In the preparation method, 1-allyl-3-methylimidazolium hexafluorophosphate or 1-allyl-3-methylimidazolium bis [(trifluoromethyl)sulfonyl] imide ionic liquid is taken as a coating material; and a layer of ionic liquid and hydroxy silicone oil composite coating is chemically bonded on the surface of a quartz fiber by a method for combining the sol-gel with free radical initiated crosslinking. The sol-gel ionic liquid solid phase microextraction extraction fiber prepared by the technical scheme can be directly combined with gas chromatogram, and has the advantages of porous surface structure, high thermal stability, high solvent washing resistance, wide pH application range, high repeatability, good extraction effect on strongly polar phenol environmental estrogen, arylamine and non-polar polycyclic aromatic hydrocarbon, and good application prospects in the fields of environmental monitoring, food sanitation, inspection and quarantine, and the like.

Owner:HUAZHONG AGRI UNIV

Catechinic acid fiber blended deodorization flame-retardant woven fabric and manufacturing method thereof

ActiveCN104726994AVersatileImprove technical indicatorsFlame-proof filament manufactureMelt spinning methodsFiberPolyethylene glycol

The invention discloses catechinic acid fiber blended deodorization flame-retardant woven fabric. Raw materials of needed warp and needed weft for weaving comprise, by weight, 29 to 35 parts of syndiotactic polypropylene, 18 to 23 parts of polylactic acid, 8 to 12 parts of polyhydroxybutyrate, 3 to 5 parts of montmorillonoid, 0.02 to 0.05 part of canthaxanthin, 0.4 to 0.8 part of diprophylline, 0.5 to 0.9 part of calcium chloride, 23 to 28 parts of catechinic acid fibers, 25 to 30 parts of reed fibers, 18 to 24 parts of flame-retardant fibers, 17 to 23 parts of Lenzing modal fibers, 19 to 27 parts of zein fibers, 7 to 9 parts of oleic acid polyethylene glycol ester, 10 to 14 parts of ethylene glycol monoethyl ether acetate, 3 to 4 parts of peppermint, 2 to 5 parts of isatis roots, 1 to 3 parts of rheum officinale, 85 to 100 parts of 1-butyl-3-methylimidazolium acetate, 95 to 105 parts of 1-allyl-3-methylimidazolium chloride, 4 to 6 parts of auxiliaries and a proper amount of water. The fabric has the advantages of being resistant to odor, flames and abrasion, capable of absorbing sound and isolating heat and the like.

Owner:JIXI YUANDAO AGRI IND TECH

Woven fabric capable of releasing negative ions and preparation method thereof

InactiveCN105155030AImprove the environmentImprove the defect of single functionConjugated cellulose/protein artificial filamentsConjugated synthetic polymer artificial filamentsNoise reductionIon

The invention discloses woven fabric capable of releasing negative ions. The woven fabric is woven by warp yarn and weft yarn through an air jet loom, and the warp yarn and the weft yarn are prepared from raw materials in parts by weight as follows: 25-35 parts of polypropylene resin, 18-22 parts of polyethylene, 1-2 parts of silica, 3-5 parts of tourmaline powder, 15-20 parts of alginate fiber, 18-28 parts of Bamdal fiber, 24-30 parts of fine denier polyamide yarn, 4-5 parts of polyethylene wax, 3-6 parts of methylene diphenyl diisocyanate, 10-14 parts of methyl acrylate, 2-4 parts of folium artemisiae argyi, 3-5 parts of mint, 80-100 parts of 1-butyl-3-methylimidazolium acetate, 100-110 parts of 1-allyl-3-methylimidazolium chloride, an appropriate amount of water and 4-7 parts of an auxiliary. The fabric has multiple functions, can release the negative ions, improves the inner environment of an automobile and has the advantages of noise reduction, thermal insulation, moisture absorption, breathability, wear resistance, waterproofness, pilling resistance and the like, further, the production is simple and easy, and the cost is low.

Owner:安徽省中日农业环保科技有限公司

Processing technology for high wear-resistant and antibacterial denim fabric

InactiveCN107587233AImprove efficiencyNo pollution in the processMonocomponent cellulose artificial filamentWoven fabricsFiberWear resistant

The invention provides a processing technology for a high wear-resistant and antibacterial denim fabric, and belongs to the technical field of textile fabric. The technical problem that an exiting high wear-resistant and antibacterial denim fabric is complex in processing technology is solved. The processing technology for the high wear-resistant and antibacterial denim fabric is characterized bycomprising the following step that 1, raw materials are prepared, wherein the fabric is made from, by weight, 12-20 parts of spandex fiber, 15-22 parts of cotton fiber, 16-18 parts of bast fiber, 20-25 parts of regenerated fiber, 10-12 parts of fructus lycii, 2-3 parts of ginger, 4-5 prats of folium artemisiae argyi, 15-20 parts of wheat straw, 5-6 parts of lignocellulose, 8-9 parts of soybean protein fiber, 0.4-0.5 part of tea tree oil, 5-6 parts of calcium carbonate, 6-7 parts of hydrochloric acid, 40-50 parts of tencel, 0.5-0.6 part of nano-zirconia, 4-6 parts of paraffin, 100-110 parts of1-butyl-3-methylimidazolium acetate, 98-105 parts of 1-allyl-3-methylimidazolium chloride and 30-40 parts of water. The processing technology has the advantage of being simple.

Owner:海宁市成达经编股份有限公司

Antistatic textile fabric and preparing method thereof

ActiveCN110528141ASuitable for large-scale productionWide variety of sourcesElectroconductive/antistatic filament manufactureConjugated cellulose/protein artificial filamentsMethoxyacetic acidFiber

The invention discloses an antistatic textile fabric. The antistatic textile fabric is characterized by being prepared from, by weight, 40-60 parts of antistatic functional fiber, 20-30 parts of otherfiber and 7-15 parts of alginic acid fiber, The antistatic functional fiber is prepared by mixing a methyl 2-methoxy-2-(prop-2-enoylamino)acetate / 1-allyl-3-methylimidazolium chloride / vinyl-functionalized Zr-MOFs / 1-[3-(triethoxysilyl)propyl]-1H-pyrrole-2,5-dione / acrylonitrile / monovinyl-terminated polydimethylsiloxane copolymer with carboxymethyl cellulose sodium. The invention further discloses apreparing method of the antistatic textile fabric. The antistatic textile fabric has the advantages of remarkable antistatic effect, excellent sweat absorbing property, high conductivity, good thermal insulation effect, high wearing comfort level and high water absorption and decontamination capacity.

Owner:无锡兴之盛针织有限公司

Electrolyte solution for dye-sensitized solar cells

ActiveCN101615513AImprove performanceGood electrolyte performanceLight-sensitive devicesSolid-state devicesIodidePhysical chemistry

The invention relates to electrolyte solution for dye-sensitized solar cells, in particular to electrolyte solution. The electrolyte solution comprises i) alkyl substituted imidazolium iodide; ii) 1-allyl-3-methylimidazolium iodide; iii) LiI; iv) I2; and vii) solvent. The invention also relates to application of the electrolyte solution during preparing dye-sensitized solar cells as well as dye-sensitized solar cells comprising the electrolyte solution. The electrolyte solution reduces DMPII dosage and electrolyte solution viscosity, and solves the problem of yellow precipitate in electrolyte solution; therefore, the electrolyte solution is propitious to the transmission of electron and the increase of solar cell efficiency.

Owner:ENN SCI & TECH DEV

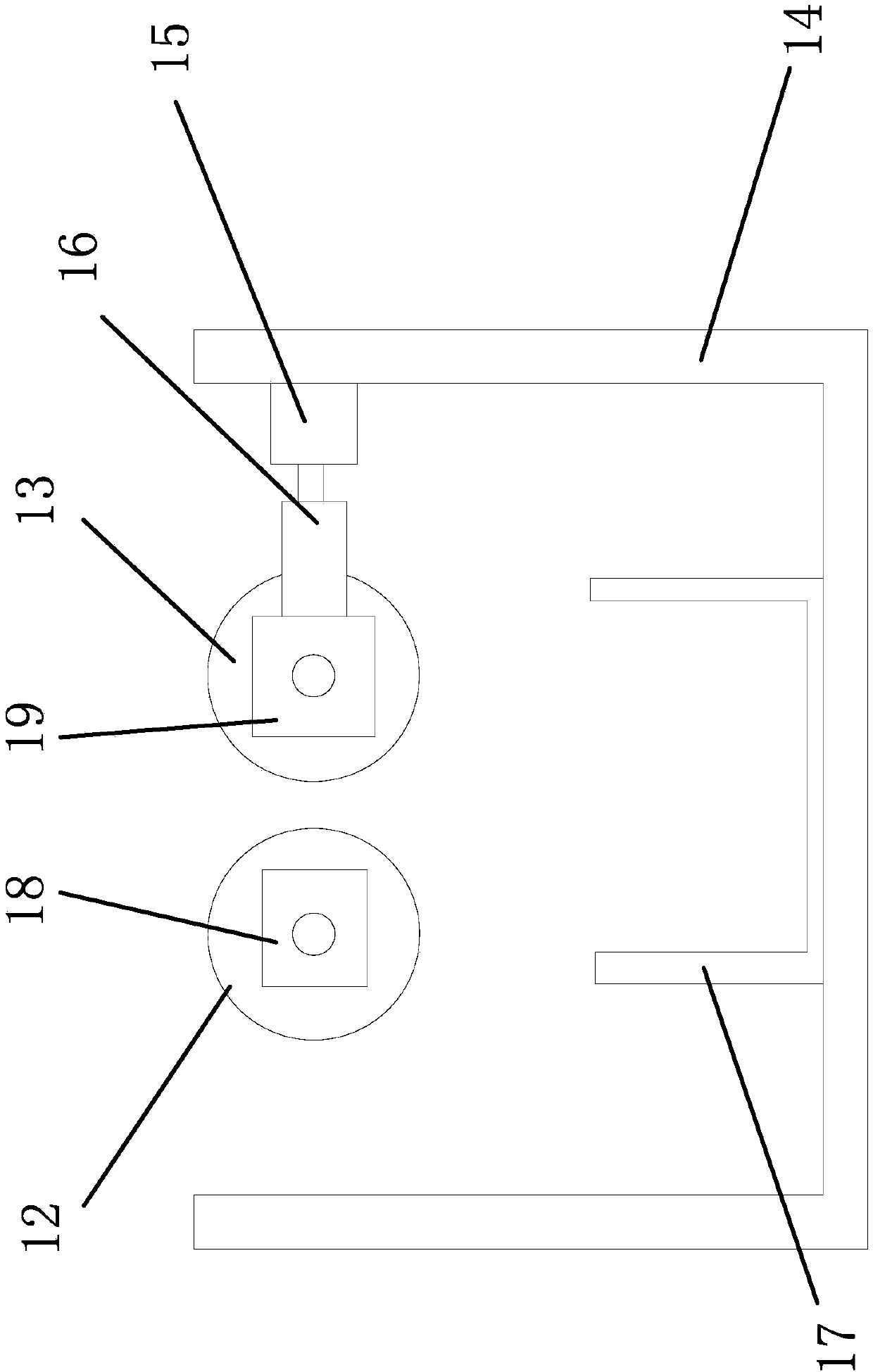

3D printing chitosan material using ionic liquid as medium, and preparation method thereof

ActiveCN110330697ARealize 3D modelingValid matchAdditive manufacturing apparatusChloride1-allyl-3-methylimidazolium bromide

The present invention relates to a 3D printing chitosan material using an ionic liquid as a medium, and a preparation method and an application thereof. The medium comprises at least an ionic liquid,and the ionic liquid is at least one of 1-allyl-3-methylimidazolium bromide, 1-allyl-3-methylimidazolium chloride, 1-ethyl-3-methylimidazolium chloride, 1-butyl-3-methylimidazolium chloride, 1-butyl-3-methylimidazolium acetate, 1-ethyl-3-methylimidazolium acetate, 1-ethyl-3-methylimidazolium dimethylphosphate and 1-carboxymethyl-3-methylimidazolium chloride. The 3D printing chitosan material usingthe ionic liquid as the medium has the advantages of effective realization of the three-dimensional molding of the chitosan material, simple steps, simplicity in operation, and designing and preparation of a three-dimensional chitosan functional material with different forms as needed.

Owner:INST OF BIOMEDICAL ENG CHINESE ACAD OF MEDICAL SCI

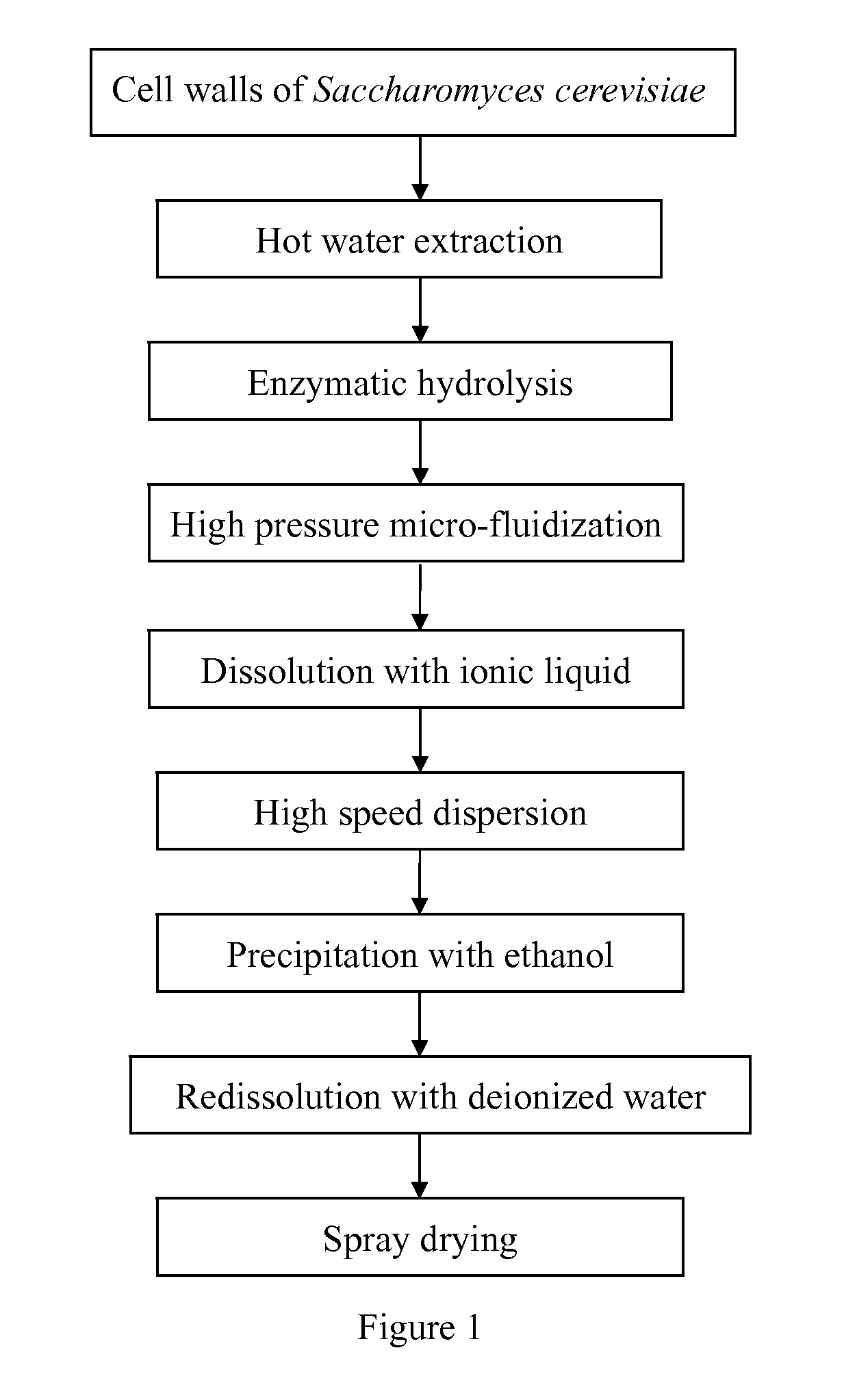

Method for Preparing Yeast Beta-D-Glucan Using Solubilization Technology Based on Molecular Assembly

The present invention provides a method for preparing yeast beta-D-glucan using a solubilization technology based on molecular assembly, comprising the following steps: (1) micro-fluidizing an enzymatic hydrolysate of yeast cell walls at 70 to 200 MPa, and then centrifuging to obtain a precipitate; (2) resuspending the precipitate obtained in step (1) with a ionic liquid, then dispersing to obtain a solution; wherein the ionic liquid is 1-ethyl-3-methylimidazolium acetate or 1-allyl-3-methylimidazolium chloride; (3) centrifuging the solution obtained in step (2), and then adding ethanol, centrifuging and collecting a precipitate; (4) resuspending the precipitate obtained in step (3) with water, then centrifuging and collecting a supernatant. Preferably, the method further comprises (5): spray drying the supernatant obtained in step (4) to obtain a yeast beta-D-glucan powder. The yeast beta-D-glucan obtained in the present invention has high purity and good solubility, which advantageously enlarges its application range.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

Method for preparing cellulose membrane by utilizing rice straw

The invention provides a method for preparing a cellulose membrane by utilizing rice straw, which relates to the field of the utilization of crop straw. The method comprises the following steps: pre-treating straw, dissolving cellulose, and molding. The method specifically comprises the following steps: firstly pre-treating the straw in an ethanol aqueous solution and drying; then melting 1-allyl-3-methylimidazolium chloride ion liquid, adding the pre-treated rice straw, continuously heating, preserving the heat, dissolving, and obtaining a cellulose ion liquid solution; and then smearing thesolution by using a smearing machine to form a membrane, and drying to obtain the cellulose membrane. According to the method for preparing the cellulose membrane by utilizing rice straw provided bythe invention, the ethanol aqueous solution is firstly used for pre-treating the rice straw so as to remove lignin and hemicellulose, then the ion liquid is used for dissolving the cellulose to obtainthe cellulose ion liquid solution, and finally the solution is molded to obtain the cellulose membrane. The entire process is free from emission of pollutants, the environmental pollution can be avoided, and the utilization rate of the cellulose is relatively high.

Owner:柳州市柳科科技有限公司

Negative oxygen ion-release health cashmere composite fiber and manufacturing method thereof

InactiveCN104911734AIncrease added valueEffective release of active negative oxygen ionsConjugated cellulose/protein artificial filamentsConjugated synthetic polymer artificial filamentsOxygen ionsGinkgo

The invention discloses a negative oxygen ion-release health cashmere composite fiber. The fiber is prepared from 30-40 parts by weight of cashmere fibers, 13-16 parts by weight of polyacrylonitrile fibers, 15-18 parts by weight of soybean fibers, 16-20 parts by weight of bombax ceiba fibers, 0.3-0.6 parts by weight of sodium laurate, 2-3 parts by weight of tourmalinite powder, 1-2 parts by weight of diisocyanate, 5-8 parts by weight of isopropyl palmitate, 10-20 parts by weight of agricultural emulsifier No.600, 3-5 parts by weight of ginkgo leaf, 2-4 parts by weight of lotus leaf, 1-2 parts by weight of radix bupleuri, 100-110 parts by weight of 1-ethyl-3-methylimidazolium acetate, 95-105 parts by weight of 1-allyl-3-methylimidazolium chloride, 20-30 parts by weight of an auxiliary agent and a proper amount of water. The polyacrylonitrile fibers, soybean fibers, bombax ceiba fibers and cashmere fibers are immersed in the Chinese herbal medicine-modified anti-pilling auxiliary agent and modified tourmalinite powder is added into the mixture so that the cashmere composite fibers are prepared. The cashmere composite fiber can effectively release active negative oxygen ions, has the advantages of antibiosis, mildew resistance and wear resistance, reduces cashmere surface friction, improves cashmere fabric anti-pilling performances, is soft, slip and fluffy, has warming effects and further improves a cashmere added value.

Owner:TONGLING HONGZHENG NETWORK SCI & TECH CO LTD

Flame-retardant graphene conducting material and preparation method thereof

InactiveCN106046734AImprove performanceImprove fire performanceNon-conductive material with dispersed conductive materialN dimethylformamideLithium hydroxide

The invention discloses a flame-retardant graphene conducting material. The flame-retardant graphene conducting material comprises, by weight, 0.1-0.2 part of 2-benzimidazolethiol, 3-4 parts of palm wax, 1-2 parts of 1-allyl-3-methylimidazolium chloride, 1.7-2 parts of phosphoric acid, 2-3 parts of lithium hydroxide, 0.8-1 part of ferrous sulfate, 0.1-0.2 part of glucose, 6-7 parts of acetylene black, 81-90 parts of unsaturated polyester resin, 600-700 parts of N,N-dimethylformamide, 27-30 parts of graphene oxide, 26-30 parts of hydrazine hydrate, 0.5-1 part of aluminum ammonium sulfate, 3-4 parts of dioctyl azelate, 4-5 parts of xylitol, 0.6-1 part of alkanolamide, 3-4 parts of zinc hydroxystannate, 1-2 parts of decabromodiphenyl ether, 3-5 parts of talcum powder and 1-2 parts of sodium alkyl benzene sulfonate. The flame-retardant graphene conducting material has the advantage that the chloride modified graphene with high conductivity can well disperse in the unsaturated polyester resin after being mixed with the acetylene black to form the high-conductivity compound material.

Owner:SUZHOU ZIJIN PLASTIC

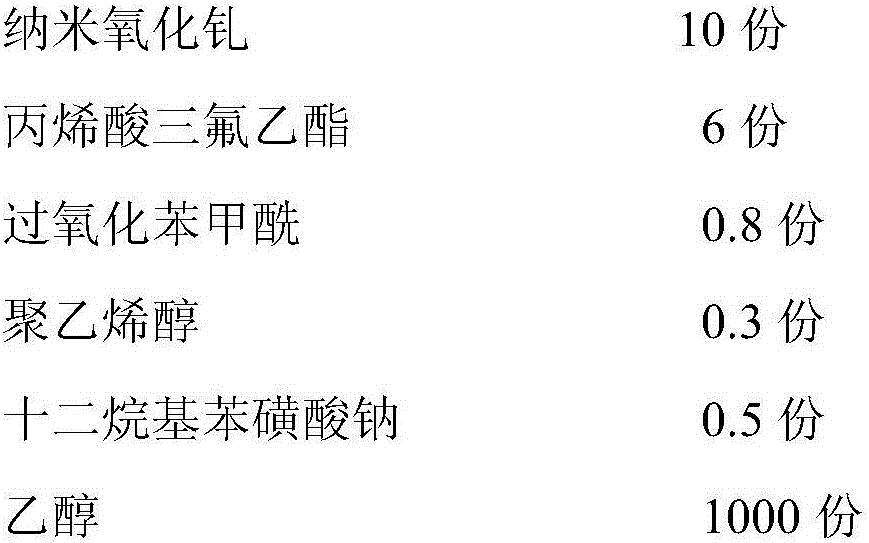

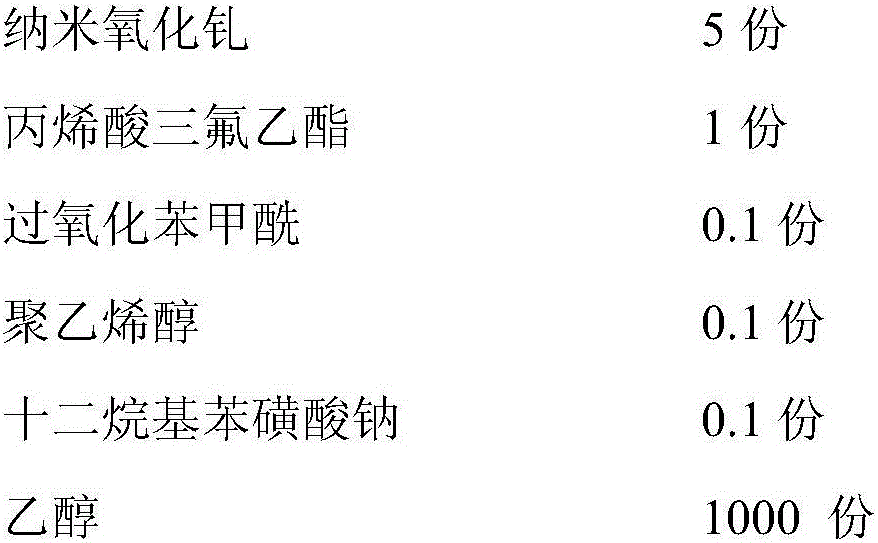

A kind of preparation method of enhanced heat transfer nano-refrigerant

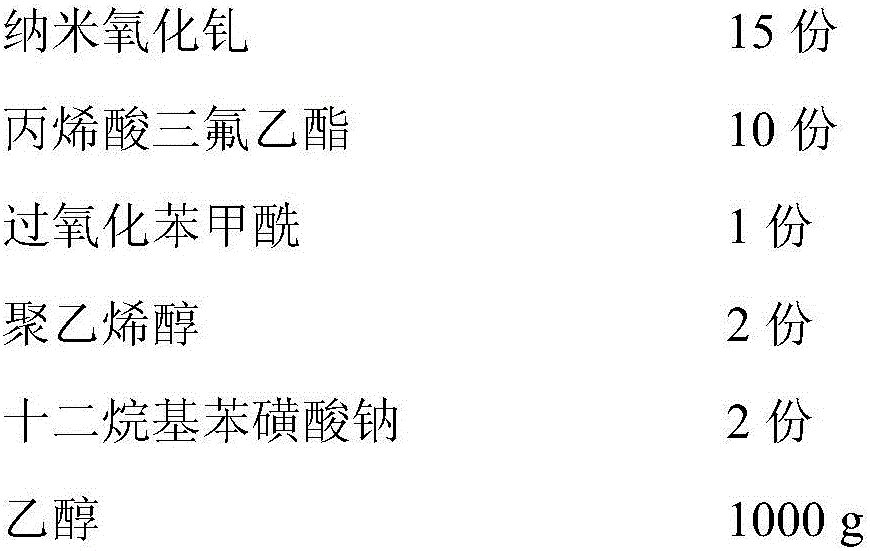

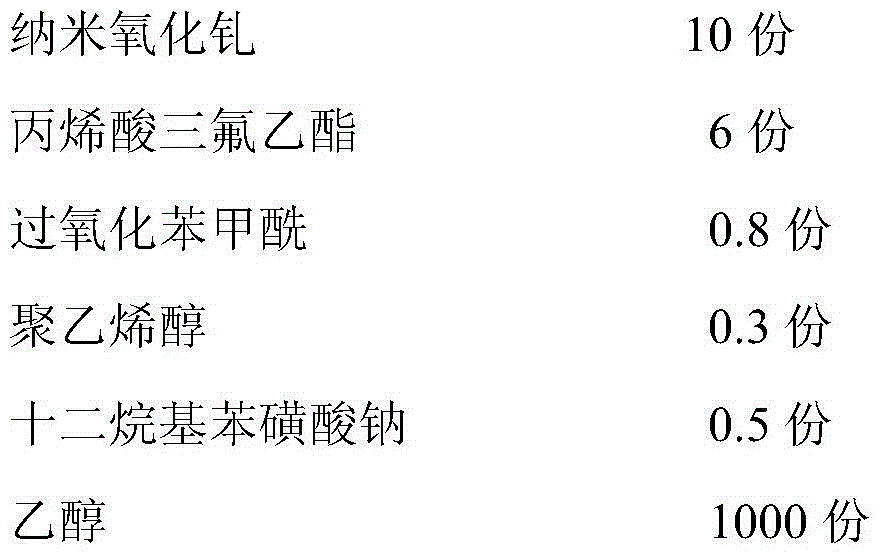

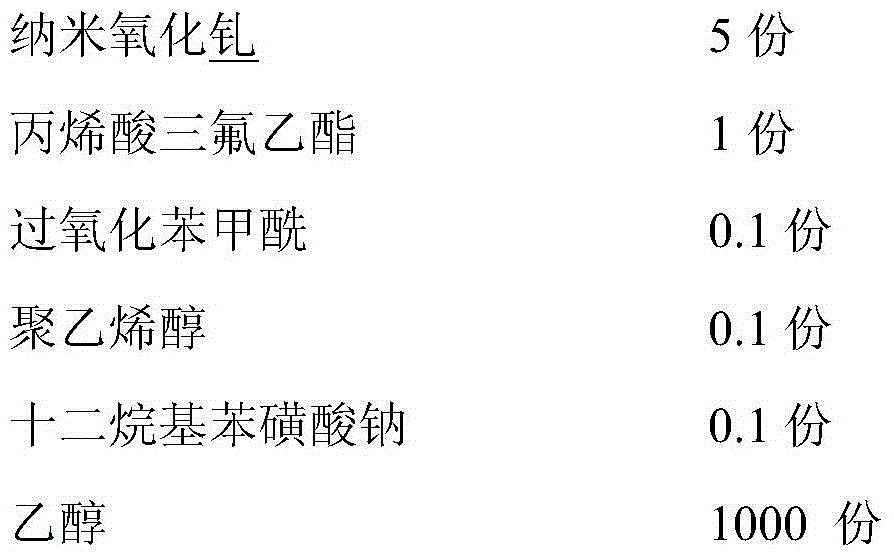

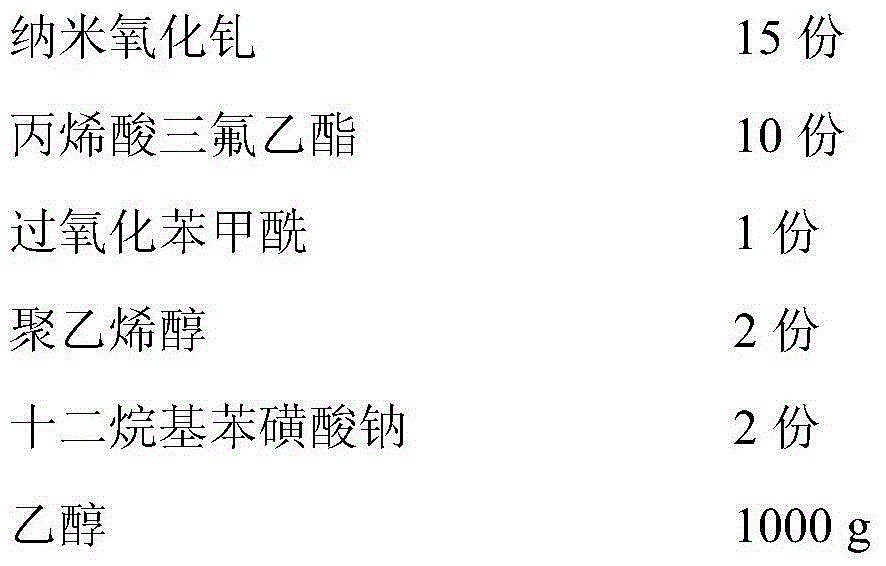

ActiveCN104403639BSmall sizeSmall specific surface areaHeat-exchange elementsBenzoyl peroxidePolyvinyl alcohol

The invention discloses a preparation method for an enhanced heat transfer type nano-refrigerant. The method comprises the steps of: (a) dispersing 5-15 parts by weight of nano-gadolinium oxide into 1000 parts of ethanol, then adding 1-10 parts of a trifluoroethyl acrylate monomer, 0.1-1 part of benzoyl peroxide, 0.1-2 parts of polyvinyl alcohol and 0.1-2 parts of sodium dodecyl benzene sulfonate to carry out reaction at 60-80DEG C for 6-15h, thus obtaining a surface polymerized nano-gadolinium oxide micro-suspension solution; (b) subjecting the nano-gadolinium oxide micro-suspension solution obtained in step (a) to liquid phase blending with 2, 3, 3, 3-tetrafluoropropene, 1, 2, 3, 3, 3-pentafluoropropene, 1-allyl-3-methylimidazolium hexafluorophosphate in a mass ratio of 1:8000-60000:10-40000:0.1-0.5, thus obtaining the enhanced heat transfer type nano-refrigerant. The method provided by the invention has the advantages of simple process, low cost, green and environmental protection, and product with excellent heat transfer performance.

Owner:JUHUA GROUP TECH CENT

Method for preparing cellulose composite membrane by utilizing rice straw

InactiveCN107880292AIncrease profitImprove mechanical propertiesPaper material treatmentCelluloseGlycerol

The invention provides a method for preparing a cellulose composite membrane by utilizing rice straw, which relates to the field of the utilization of crop straw. The method comprises the following steps: pre-treating the straw, dissolving cellulose, preparing a mixed solution, and molding. Specifically, the method comprises the following steps: pre-treating the straw in an ethanol aqueous solution, and drying; then melting 1-allyl-3-methylimidazolium chloride ion liquid, adding the pre-treated rice straw, continuously heating, preserving the heat, dissolving, and obtaining a cellulose ion liquid solution; and finally adding polyvinyl alcohol, corn starch and glycerinum, mixing to obtain a mixed solution, smearing the mixed solution by using a smearing machine to form a membrane, and drying to obtain the cellulose membrane. The ethanol aqueous solution is firstly used for pre-treating the rice straw, then the ion liquid is adopted to dissolve the cellulose, the corn starch, the polyvinyl alcohol and the glycerinum are added, and finally the mixture are molded to obtain the cellulose composite membrane. The entire process is free from emission of pollutants, the environmental pollution can be avoided, the utilization rate of the cellulose is relatively high, and the prepared composite membrane has good mechanical properties.

Owner:柳州市柳科科技有限公司

Preparation method for enhanced heat transfer type nano-refrigerant

ActiveCN104403639AImprove thermal conductivityHigh adiabatic temperature changeHeat-exchange elementsEnvironmental resistanceBenzoyl peroxide

The invention discloses a preparation method for an enhanced heat transfer type nano-refrigerant. The method comprises the steps of: (a) dispersing 5-15 parts by weight of nano-gadolinium oxide into 1000 parts of ethanol, then adding 1-10 parts of a trifluoroethyl acrylate monomer, 0.1-1 part of benzoyl peroxide, 0.1-2 parts of polyvinyl alcohol and 0.1-2 parts of sodium dodecyl benzene sulfonate to carry out reaction at 60-80DEG C for 6-15h, thus obtaining a surface polymerized nano-gadolinium oxide micro-suspension solution; (b) subjecting the nano-gadolinium oxide micro-suspension solution obtained in step (a) to liquid phase blending with 2, 3, 3, 3-tetrafluoropropene, 1, 2, 3, 3, 3-pentafluoropropene, 1-allyl-3-methylimidazolium hexafluorophosphate in a mass ratio of 1:8000-60000:10-40000:0.1-0.5, thus obtaining the enhanced heat transfer type nano-refrigerant. The method provided by the invention has the advantages of simple process, low cost, green and environmental protection, and product with excellent heat transfer performance.

Owner:JUHUA GROUP TECH CENT

Polylactic acid fiber-containing ultraviolet resistant cashmere composite fiber and manufacturing method thereof

InactiveCN104911736AUV resistantGood drapabilityConjugated cellulose/protein artificial filamentsConjugated synthetic polymer artificial filamentsUltravioletPyrophosphate

The invention discloses a polylactic acid fiber-containing ultraviolet resistant cashmere composite fiber. The fiber is prepared from 25-31 parts by weight of white cashmere, 14-18 parts by weight of camel hair, 17-20 parts by weight of corn fibers, 9-13 parts by weight of black bamboo charcoal fibers, 8-14 parts by weight of milk protein fibers, 20-24 parts by weight of polylactic acid fibers, 7-9 parts by weight of silk, 2-4 parts by weight of active carbon, 0.3-0.6 parts by weight of waterless sodium acid pyrophosphate, 4-7 parts by weight of polytetramethylene-oxide glycol, 3-5 parts by weight of ning-emulsifier 31, 2-3 parts by weight of folium artemisiae argyi, 1-2 parts by weight of cocklebur fruit, 3-5 parts by weight of root of kudzu vine, 85-95 parts by weight of 1-ethyl-3-methylimidazolium acetate, 90-100 parts by weight of 1-allyl-3-methylimidazolium chloride, 23-26 parts by weight of an auxiliary agent and a proper amount of water. Polylactic acid fibers are used in raw materials and the mixture is mixed with other fibers and cashmere so that the cashmere composite fibers are obtained. The cashmere composite fiber can solves the problems of single cashmere fibers. A cashmere product prepared from the cashmere composite fibers is lighter and thinner. Through use of active carbon and other effective components, the blended cashmere composite fibers have special functions of UV resistance, good drapability, antibiosis, moth-eaten resistance, wear resistance and warming and have a wide market prospect.

Owner:TONGLING HONGZHENG NETWORK SCI & TECH CO LTD

Cationic biomacromolecular flocculant and preparation method thereof

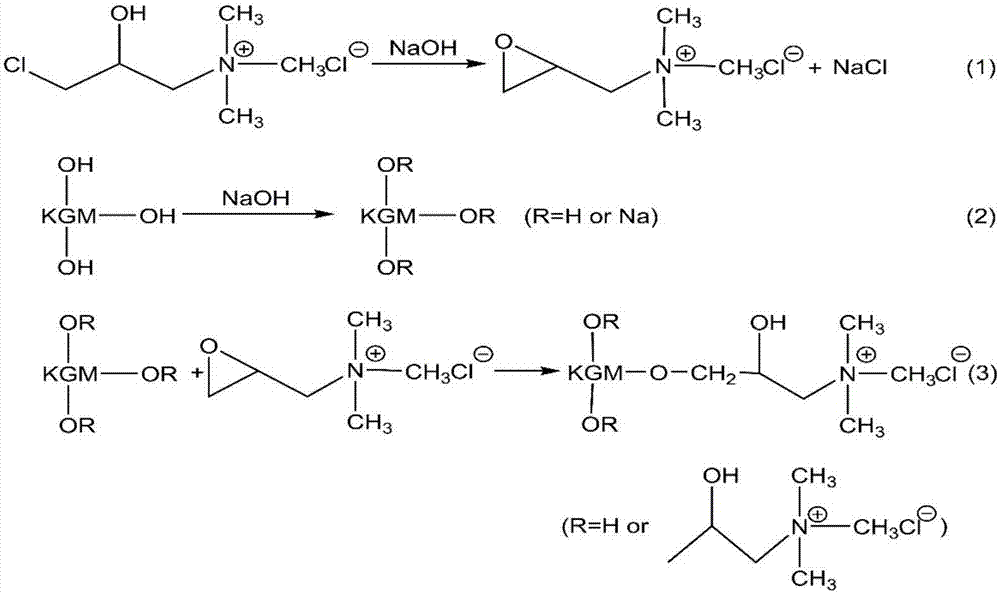

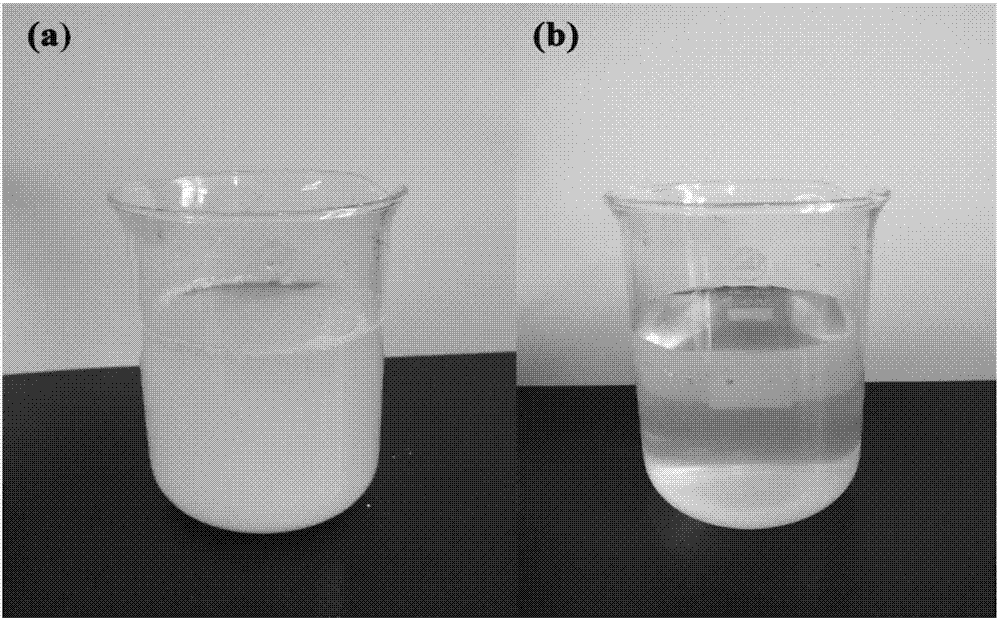

InactiveCN107573440AGood flocculation effectRealize efficient modificationWater/sewage treatment by flocculation/precipitationSolventBiological macromolecule

The invention relates to a cationic biomacromolecular flocculant and a preparation method thereof. The preparation method comprises the following steps: with refined konjak powder as a raw material, removing impurities from the refined konjak powder by using ethanol to obtain konjac glucomannan, then dissolving the konjac glucomannan into ionic liquid, and carrying out an etherification reaction among the konjac glucomannan, a cationic etherifying agent and sodium hydroxide in the solution to obtain the cationic biomacromolecular flocculant, wherein the degree of cationic substitution is 0.16-0.45. According to the preparation method, the ionic liquid 1-allyl-3-methylimidazolium (AMIMCl) chloride prepared from N-methylimidazole and allyl chloride is used as a biomacromolecular solvent, a nucleophilic reagent sodium hydroxide is used as an initiator, 3-chloro-2-hydroxypropyl trimethyl ammonium chloride (CHPTAC) is used as the etherifying agent, the KGM (konjac glucomannan) is modified on the basis of a mechanism that the etherification reaction is performed on hydroxyl groups on a molecular chain of biopolysaccharide, and the cationic biopolysaccharide flocculant is prepared, so that the application range of the KGM is widened and a good flocculating effect is achieved.

Owner:WUHAN UNIV OF TECH

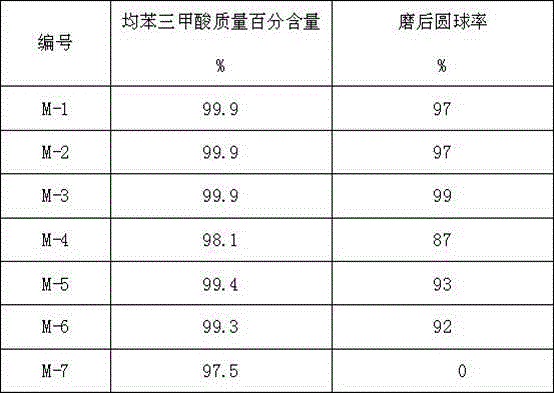

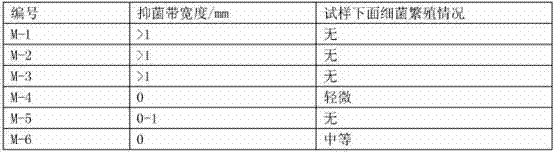

Preparation method of adsorbent for refining trimesic acid

InactiveCN105777970AExtended service lifeReduce breakageOther chemical processesCross-linkTetrafluoroborate

The invention relates to a preparation method of an adsorbent for refining trimesic acid. Triallyl cyanurate, p-fluorocinnamaldehyde, 1-allyl-3-methylimidazolium tetrafluoroborate and 4-hydroxynonenal are introduced in styrene cross-linking polymerization to serve as comonomers to prepare the adsorbent.

Owner:张玲

Antistatic cashmere composite fiber containing stainless steel fiber and manufacturing method thereof

The invention discloses antistatic cashmere composite fiber containing stainless steel fiber. The antistatic cashmere composite fiber is prepared by raw materials comprising, by weight, 30-35 parts of berber Fleece, 10-13 parts of rabbit hair, 6-9 parts of soybean protein fiber, 7-10 parts of nanometer bamboo-carbon fiber, 11-14 parts of stainless steel fiber, 5-8 parts of aloe fiber, 4-7 parts of polyethylene glycol distearate, 0.02-0.04 parts of lemon oil, 1.3-2.5 parts of polytetrahydrofuran glycol, 3-5 parts of ethanol amine, 0.6-1.1 parts of nano-TiO2, 2-4 parts of artificial zeolite powder, 1-3 parts of cimicifugae foetidae, 3-4 parts of Mangnolia officinalis, 4-6 parts of pineapple leaves, 110-120 parts of 1-ethyl-3-methylimidazolium acetate, 100-110 parts of 1-allyl-3-methylimidazolium chloride, 20-24 parts of addition agent and appropriate amount of water. The antistatic cashmere composite fiber prepared by the invention has special functions of being anti-static, anti-microbial, mothproof, wear resistant, and anti-radiation and the like.

Owner:TONGLING HONGZHENG NETWORK SCI & TECH CO LTD

Thermal and wear resistant mercerized wool woven fabric and manufacturing method thereof

InactiveCN105133078AWarm and wear-resistantSound-absorbing and antibacterialWoven fabricsConjugated synthetic polymer artificial filamentsFiberPolyester

The invention discloses thermal and wear resistant mercerized wool woven fabric which is prepared from the following raw materials in parts by weight: 31-36 parts of isotactic polypropylene, 16-19 parts of chloroprene rubber, 0.3-0.8 part of aluminum sulfate, 0.7-1.2 parts of barium sulfate, 1.2-3.2 parts of salicylanilide, 2-4 parts of diatomite, 20-30 parts of mercerized wool, 23-27 parts of polyester fiber, 18-24 parts of apocynum venetum fiber, 19-26 parts of Anti-fcell, 2.4-3.6 parts of polyvinyl alcohol, 7-10 parts of 2-ethylhexyl epoxystearate, 11-14 parts of dibutyl ester, 3-5 parts of pinellia ternate, 2-4 parts of radix aucklandiae, 105-110 parts of 1-butyl-3-methylimidazolium acetate, 95-110 parts of 1-allyl-3-methylimidazolium chloride, 4-6 parts of an assistant and a proper amount of water. According to the thermal and wear resistant mercerized wool woven fabric and the manufacturing method thereof, provided by the invention, the conventional preparation technology is changed, the prepared woven fabric has the characteristics of warmth retention, wear resistance, sound absorption, antibacterial property, comfortableness, softness, and high convenience in dyeing and the like.

Owner:芜湖跃飞新型吸音材料股份有限公司

Method for preparing nano TiB2/carbon nano tube composite paste electrode sensor

InactiveCN108490050AImprove conductivityEasy to prepareMaterial electrochemical variablesTetrafluoroboratePower flow

The invention discloses a method for preparing a nano TiB2 / carbon nano tube composite paste electrode sensor. The method is characterized by comprising the following steps: pre-treating carbon nano tubes with concentrated sulfuric acid and ammonium persulfate to obtain pretreated carbon nano tubes; respectively 38-42% of nano TiB2, 23-26% of pretreated carbon nano tubes, 25-30% of 1-allyl-3-methylimidazolium tetrafluoroborate and 6-10% of glycerin into an agate mortar, and uniformly grinding to obtain the mixture carbon paste; and filling the carbon paste into a glass tube which is connected with a wire and has an inner diameter of Phi 5 mm, compacting, drying, polishing by abrasive paper for metallograph, polishing, and washing with deionized water, thereby obtaining the nano TiB2 / carbonnano tube composite paste electrode. Compared with that of an ordinary carbon paste electrode, the conductivity of the carbon paste electrode prepared in the invention is improved by 4-5 times, and the carbon paste electrode has the advantages of being wide in electrochemical window, simple in preparation method, low in cost, easy for surface renewal, low in residual current and the like. The cefixime detection sensitivity is high, and the selectivity is excellent.

Owner:UNIV OF JINAN

Spandex fiber-containing dry cleaning-resistant flame-retardant cashmere composite fiber and manufacturing method thereof

InactiveCN104911733AWith dry cleaning characteristicsAntistaticElectroconductive/antistatic filament manufactureFlame-proof filament manufactureFiberMohair

The invention discloses a spandex fiber-containing dry cleaning-resistant flame-retardant cashmere composite fiber. The fiber is prepared from 22-28 parts by weight of Tibetan antelope wool, 15-18 parts by weight of white goose down, 17-19 parts by weight of mohair fibers, 19-24 parts by weight of rice straw pulp fibers, 12-15 parts by weight of spandex fibers, 14-17 parts by weight of cuprammonium fibers, 2-4 parts by weight of nanometer far-infrared ceramic powder, 1.2-3.5 parts by weight of decabromodiphenyl oxide, 7-9 parts by weight of polypropylene glycol, 3-5 parts by weight of acrylamide, 2-3 parts by weight of pregelatinized starch, 0.4-0.8 parts by weight of magnesium chloride, 0.5-0.9 parts by weight of nanometer titanium dioxide, 1-3 parts by weight of prepared rehmannia root, 2-5 parts by weight of dendranthema indicum var aromaticum, 3-4 parts by weight of poria cocos, 85-95 parts by weight of 1-ethyl-3-methylimidazolium acetate, 90-110 parts by weight of 1-allyl-3-methylimidazolium chloride, 20-24 parts by weight of an auxiliary agent and a proper amount of water. Multiple types of fibers and Tibetan antelope wool are blended and spandex fibers and cuprammonium fibers are added into the mixture so that the cashmere composite fiber is obtained. The cashmere composite fiber has characteristics of dry cleaning resistance of spandex fibers and antistatic properties of cuprammonium fibers. Through use of other fibers and effective components, the cashmere composite fiber has the advantages of flame retardation, wear resistance, good serviceability, good processability and wide application scope.

Owner:TONGLING HONGZHENG NETWORK SCI & TECH CO LTD

Waterproof weatherability polyurethane glass cement

InactiveCN108300397AGood weather resistanceImprove aging resistanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesives8-HydroxyquinolineMaterials science

The invention discloses a waterproof weatherability polyurethane glass cement, which comprises following raw materials in parts by weight: 70 to 100 parts of polyurethane prepolymer, 10 to 25 parts ofpolyester resin, 5 to 12 parts of liquid nitrile rubber, 3 to 10 parts of chloroprene rubber, 1 to 5 parts of sodium monofluorophosphate, 2 to 5 parts of hexafluorobisphenol A, 1 to 5 parts of 1-allyl-3-methylimidazolium chloride, 2 to 5 parts of graphene, 2 to 10 parts of montmorillonite, 2 to 10 parts of molecular sieve, 2 to 5 parts of titanium dioxide, 3 to 10 parts of silicon carbide, 0.3 to2 parts of 3-isocyanatopropyl triethoxysilane, 0.5 to 3 parts of 1H, 1H, 9H-hexadecafluorononanol, 0.5 to 2 parts of 8-hydroxyquinoline, and 0.2 to 0.5 part of methyl ethyl ketone peroxide. The provided waterproof weatherability polyurethane glass cement has the advantages of high boding strength, excellent weatherability, good waterproof performance, and long service life.

Owner:天长市墨缘玻璃建材有限公司

Preparation method of 3,6-dichloropicolinic acid osmotic membrane for concentrating

ActiveCN105817149AImprove permeabilitySemi-permeable membranesOrganic chemistry4-styrylpyridineIon-exchange membranes

The invention relates to a preparation method of a 3,6-dichloropicolinic acid osmotic membrane for concentrating .A homogeneous anion exchange membrane is immersed into a mixed solution of 4-styrylpyridine, 1-allyl-3-methylimidazolium hexafluorophosphate and vinyl terephthalic acid, irradiation grafting modification is conducted, and the 3,6-dichloropicolinic acid osmotic membrane is obtained.

Owner:中新科农(山东)生态农业有限公司

Preparation method of rare earth load antibacterial agent

InactiveCN105994346ANot easy to loseGood antibacterial and antifungal effectBiocideFungicidesAlcoholMicrosphere

The invention relates to a preparation method of a rare earth-loaded antibacterial agent. A certain amount of Q high-flow rate agarose microspheres is dispersed into ethanol, and bis(pentamethylcobalt cyclopentadiene), 1-allyl-3- Methyl imidazole chloride is subjected to a polymerization reaction to obtain a rare earth-containing Q high-flow agarose microsphere microsuspension product.

Owner:王金明

Preparation method of rare earth loaded antibacterial agent

InactiveCN106962328ANot easy to loseGood antibacterial and antifungal effectBiocideAntifouling/underwater paintsCyclopenteneMicrosphere

The invention relates to a preparation method of a rare earth loaded antibacterial agent. The preparation method of the rare earth loaded antibacterial agent comprises the following steps: dispersing a certain amount of Q high-flow-speed agarose microspheres into ethanol, adding bi(pentamethyl cobalt cyclopentene) and 1-allyl-3-methylimidazolium chloride, and performing polymerization to obtain rare earth-containing Q high-flow-speed agarose microsphere micro-suspension products subjected to surface polymerization.

Owner:王金明

Abietinol-grafted composite elastic material and preparation method thereof

The invention discloses an abietinol-grafted composite elastic material. The abietinol-grafted composite elastic material is prepared from the following raw materials in parts by weight: 0.3 to 1 part of beta-hydroxyalkylamide, 3 to 4 parts of 4-dimethylamino-pyridine, 1 to 2 parts of triethylamine, 0.1 to 0.3 part of 2-bromopropionyl bromide, 1 to 2 parts of 1-allyl-3-methylimidazolium chloride, 50 to 60 parts of methyl methacrylate, 10 to 13 parts of carbon nanotube, 40 to 51 parts of n-butyl acrylate, 0.7 to 1 part of copper bromide, 1.6 to 2 parts of pentamethyl diethylenetriamine, 1 to 2 parts of copper powder, 3 to 4 parts of abietinol, 3 to 4 parts of alkenyl succinate, 0.4 to 1 part of 2-octyl-3(2h)-isothiazolone, 1 to 2 parts of triethanolamine oleic soap, 5 to 7 parts of scolecite, 0.01 to 0.02 part of divinyl benzene, 2 to 3 parts of polytetrafluoroethylene wax, 0.5 to 1 part of tert-butylhydroquinone, 6 to 8 parts of tetrahydrofuran, and a proper amount of ethylene glycol, dimethyl formamide, chloroform, thionyl chloride and 95-98% nitric acid. The abietinol-grafted composite elastic material has the advantages that by adding the abietinol, the dispersing property of filler in resin is improved, the stability and strength of a finished product are improved, and the comprehensive property of the finished product is improved.

Owner:ANHUI HUAYU PIPELINE MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com