Sol-gel ionic liquid solid phase microextraction extraction fiber and preparation method thereof

A technology of ionic liquid and extraction head, which is applied in the field of solid-phase microextraction extraction head and its preparation, can solve the problems of weak anti-solvent washing ability, limited application range, and few types of coatings, etc., and achieve high thermal and chemical stability , Expand the application range, and the effect of a wide linear range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

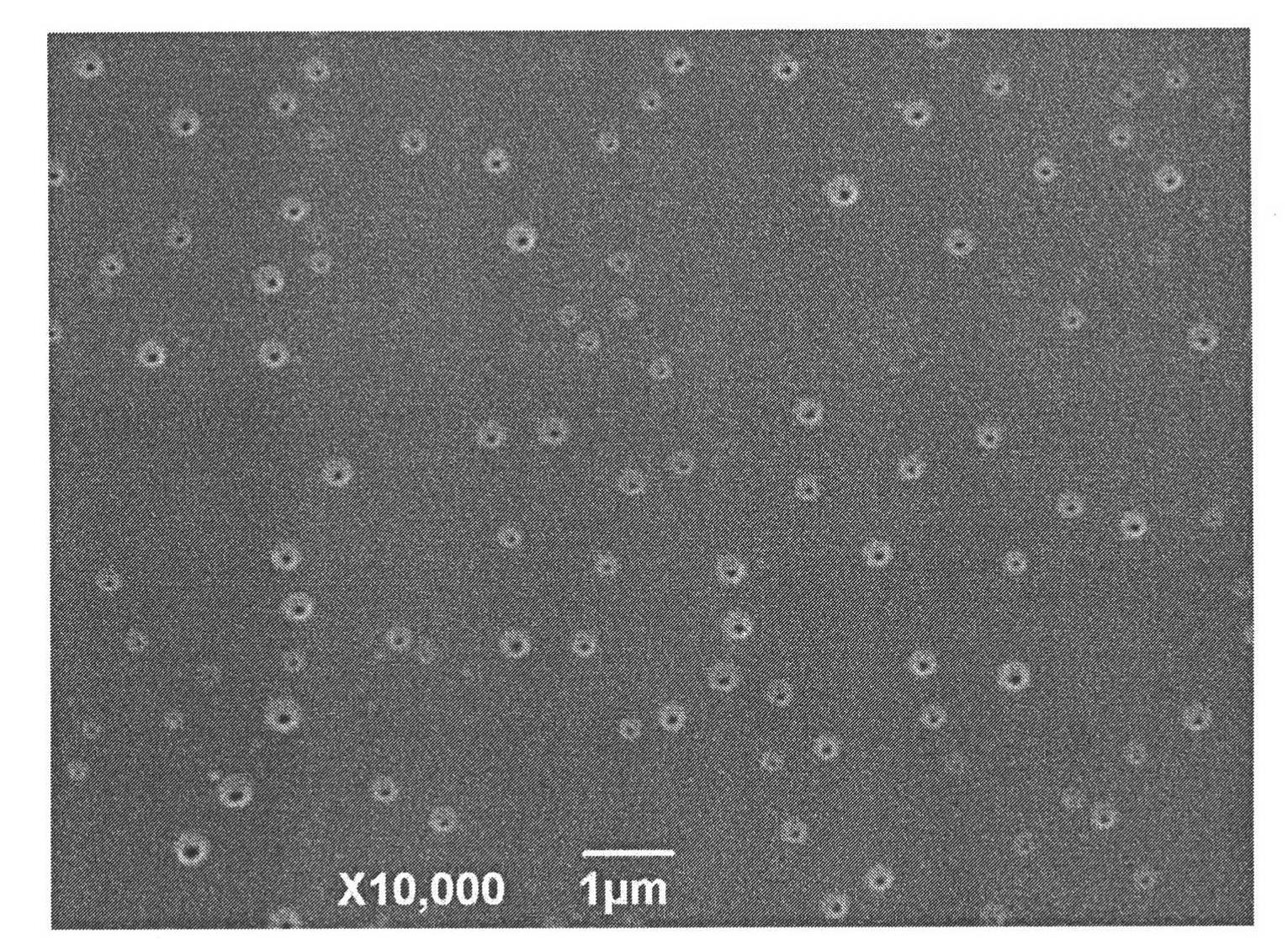

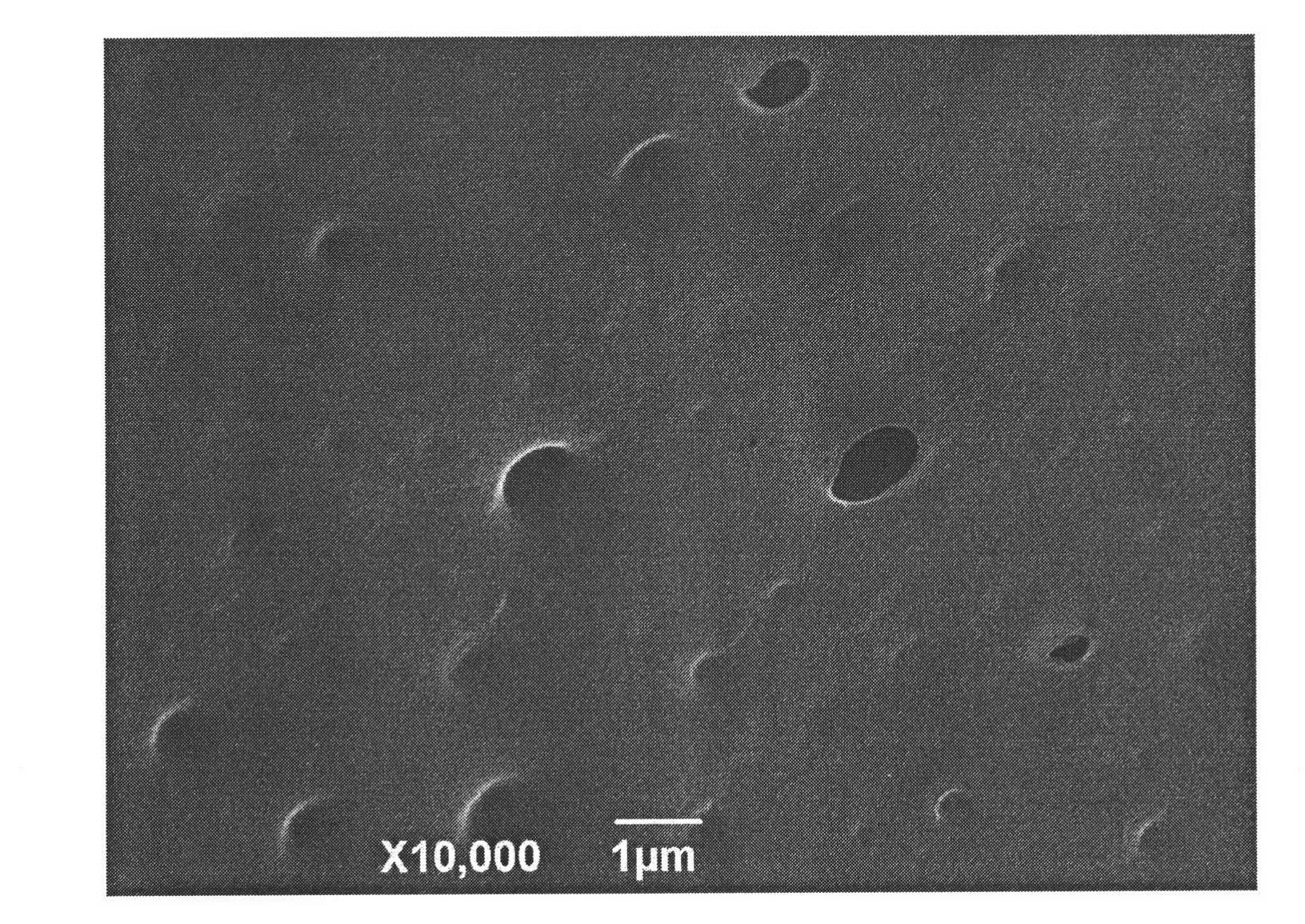

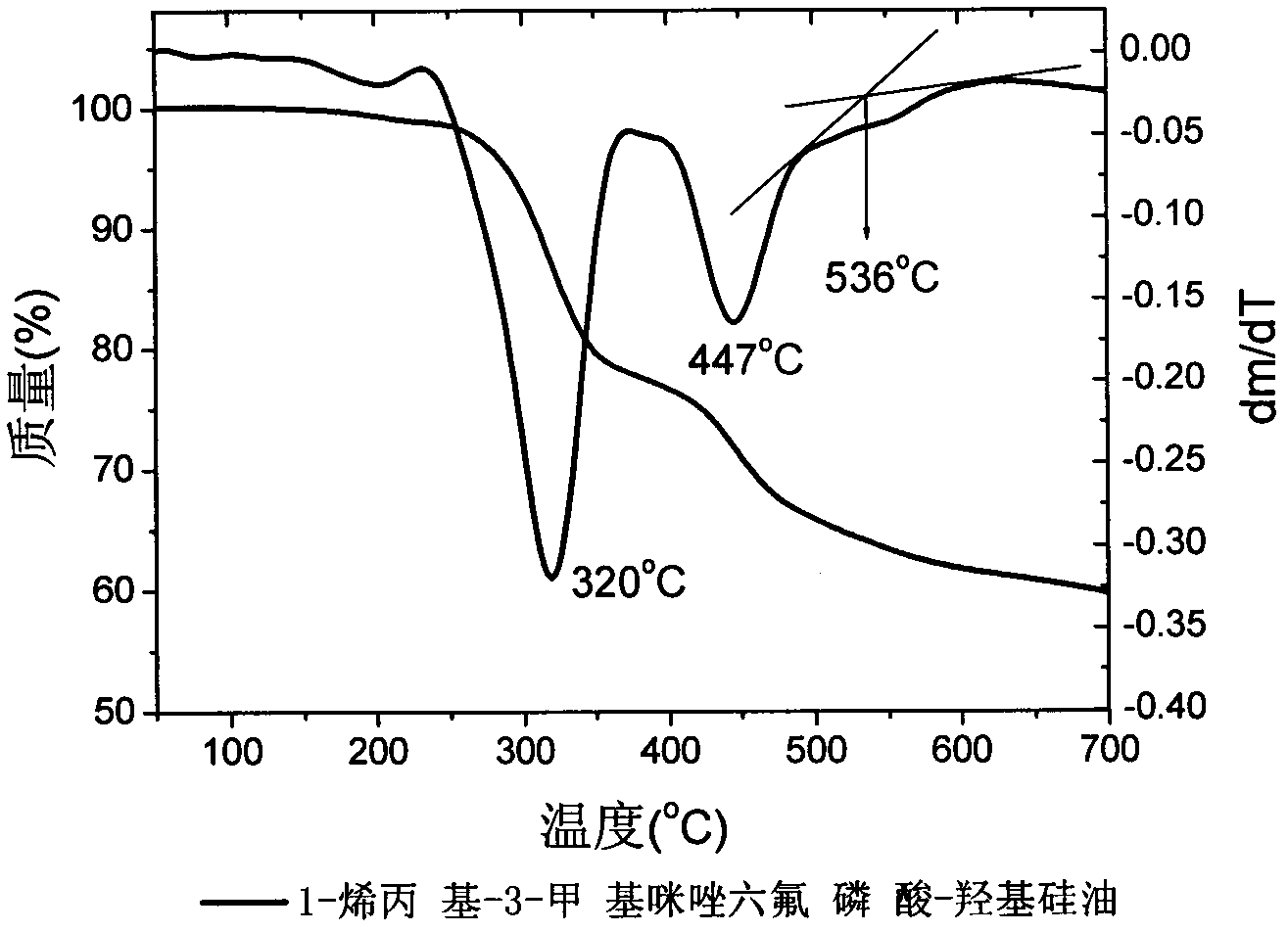

[0027]The method for preparing 1-allyl-3-methylimidazolium hexafluorophosphate ionic liquid solid-phase microextraction extraction head: take 10 mg of ionic liquid containing allyl active groups, dissolve it in 300 μL of dichloromethane, add 30 mg of hydroxyl silicone oil, Add 50 μL of tetraethoxysilane, add 30 μL of γ-methacryloxypropyl trimethoxysilane, add 5 μL of hydrogen-containing silicone oil, add 6 mg of benzophenone, ultrasonically oscillate for 5 minutes, and then add 60 μL of 5% (volume ratio) trifluoroacetic acid in water, continue ultrasonic oscillation for 8 minutes, centrifuge at 12000r / min for 8 minutes, take out the supernatant for later use. Insert one end of the dry quartz fiber whose protective layer has been removed into the sol clear solution, and place it for 5 hours, pull out the fiber vertically from the solution, repeat the operation several times to obtain a coating with a thickness of 65 μm, and place it in a desiccator for 24 hours after taking it o...

Embodiment 2

[0029] The method for preparing 1-allyl-3-methylimidazolium hexafluorophosphate ionic liquid solid-phase microextraction head: take 30 mg of ionic liquid containing allyl active groups, dissolve it in 700 μL of dichloromethane, add 60 mg of hydroxyl silicone oil, Add 100 μL tetraethoxysilane, add 50 μL γ-methacryloxypropyltrimethoxysilane, add 8 μL hydrogen-containing silicone oil, add 7 mg benzophenone, ultrasonically oscillate for 5 minutes, and then add 70 μL containing 5% (Volume ratio) trifluoroacetic acid in water, continue ultrasonic oscillation for 7 minutes, centrifuge at 10000r / min for 7 minutes, take out the supernatant for later use. Insert one end of the dry quartz fiber whose protective layer has been removed into the sol clear solution, place it for 3.5 hours, pull out the fiber vertically from the solution, repeat the operation several times to obtain a coating with a thickness of 80 μm, and place it in a desiccator for 12 hours after taking it out , and then c...

Embodiment 3

[0031] The method for preparing 1-allyl-3-methylimidazolium hexafluorophosphate ionic liquid solid-phase microextraction head: take 50 mg of ionic liquid containing allyl active groups, dissolve it in 1000 μL of dichloromethane, add 90 mg of hydroxyl silicone oil, Add 150 μL tetraethoxysilane, add 80 μL γ-methacryloxypropyltrimethoxysilane, add 15 μL hydrogen-containing silicone oil, add 8 mg benzophenone, ultrasonically oscillate for 5 minutes, and then add 80 μL containing 5% (volume ratio) trifluoroacetic acid in water, continue ultrasonic oscillation for 10 minutes, centrifuge at 16000r / min for 6 minutes, and take out the supernatant for later use. Insert one end of the dried quartz fiber whose protective layer has been removed into the sol clear solution, place it for 4 hours, pull out the fiber vertically from the solution, repeat the operation several times to obtain a coating with a thickness of 100 μm, and place it in a desiccator for 10 hours after taking it out , an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com