Double-rear earth doping modification abrasion-resistant alloy cast iron and preparation method thereof

A wear-resistant alloy and double rare earth technology, which is applied in the field of preparation of wear-resistant alloy cast iron and wear-resistant alloy cast iron, can solve the problem of large geometric dimensions and machining allowances of cylinder liners, comprehensive performance indicators not clearly specified, and the level of cylinder liner casting technology. Low-cost problems, to achieve low cost, high wear resistance, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

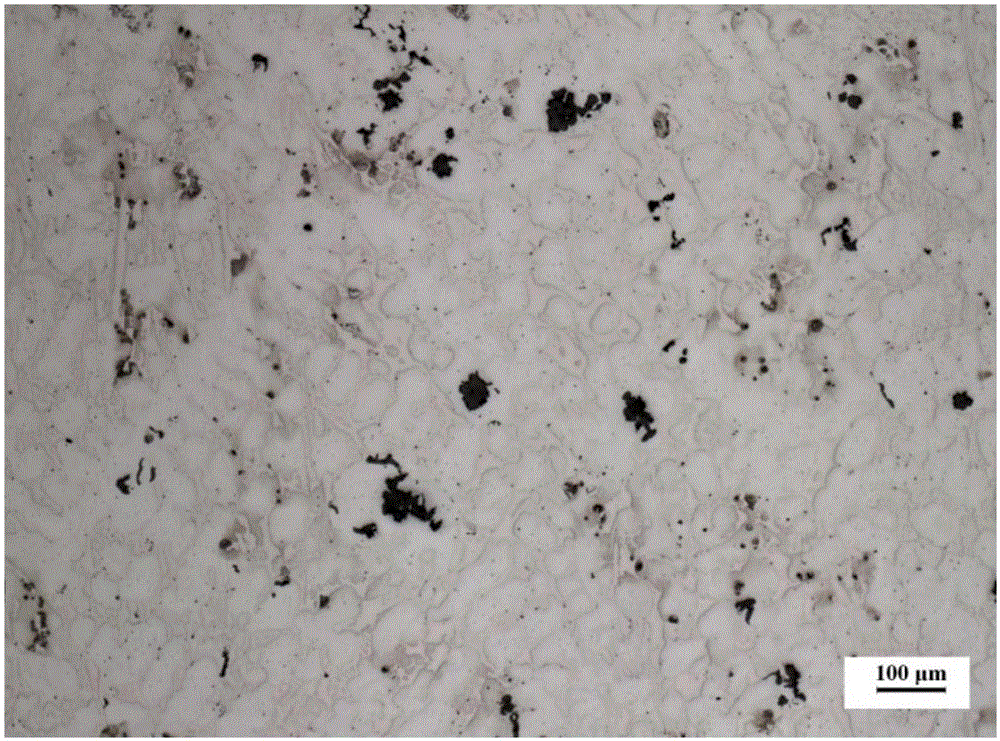

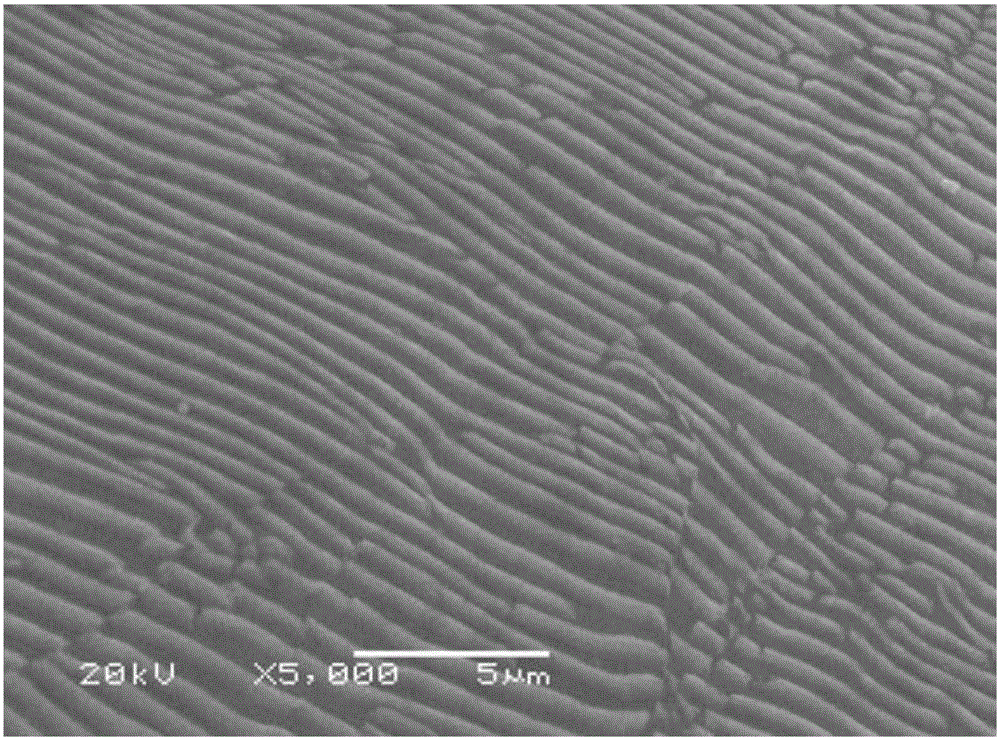

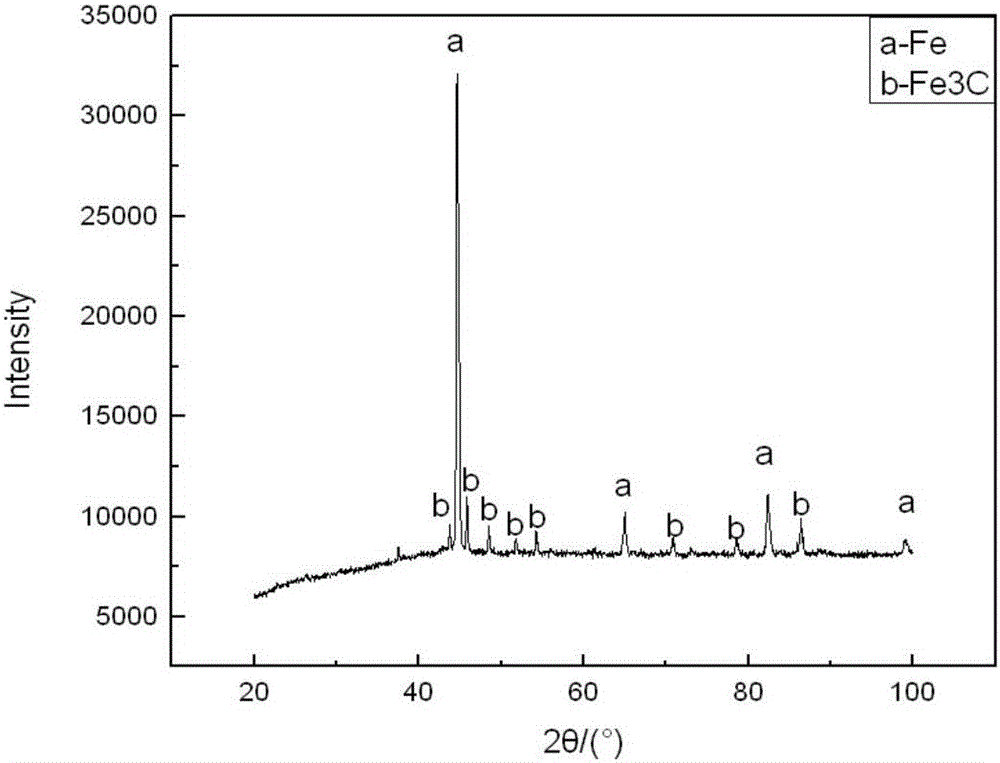

[0029] A double rare earth doped modified vermicular graphite cast iron, which is made of the following components in weight percentage: C3.1-3.2%, Si-0.9%, Mn-0.6%, Cu: 1.0-1.5%, P: 0.2-0.4 , B: 0.02-0.04%, S-0.0005%, La: 0.03-0.04%, Ce: 0.06-0.07%, and the rest are Fe and unavoidable impurities.

[0030] The preparation method comprises the following steps:

[0031] (1) Allocation of raw materials: Determine the ingredients of raw materials such as 45 steel, pig iron, ferrophosphorus, ferromanganese, ferroboron, ferrosilicon, and copper according to the above-mentioned cast iron composition ratio;

[0032] (2) Raw material smelting: In the smelting furnace, the prepared raw materials are smelted at 1450°C to obtain molten iron;

[0033] (3) Inoculation: Add the lanthanum-cerium double rare earth mixture before the ladle, and then pour the molten iron into the ladle for inoculation in the ladle. The incubation time is about 10 minutes, and the temperature of the molten iron ...

Embodiment 2

[0036] A double rare earth doped modified vermicular graphite cast iron, which is made of the following components in weight percentage: C3.1-3.2%, Si-0.9%, Mn-0.6%, Cu: 1.0-1.5%, P: 0.2-0.4 , B: 0.02-0.04%, S-0.0005%, La: 0.06-0.08%, Ce: 0.12-0.14%, and the rest are Fe and unavoidable impurities.

[0037] The preparation method comprises the following steps:

[0038] (1) Allocation of raw materials: Determine the ingredients of raw materials such as 45 steel, pig iron, ferrophosphorus, ferromanganese, ferroboron, ferrosilicon, and copper according to the above-mentioned cast iron composition ratio;

[0039] (2) Raw material smelting: In the smelting furnace, the prepared raw materials are smelted at 1500°C to obtain molten iron;

[0040] (3) Inoculation: Add the lanthanum-cerium double rare earth mixture before the ladle, and then pour the molten iron into the ladle for inoculation in the ladle. The incubation time is about 10 minutes, and the temperature of the molten iron ...

Embodiment 3

[0043] A double rare earth doped modified vermicular graphite cast iron, which is made of the following components in weight percentage: C: 3.1-3.2%, Si-0.9%, Mn-0.6%, Cu: 1.0-1.5%, P: 0.2-0.4 , B: 0.02-0.04%, S-0.0005%, La: 0.12-0.16%, Ce: 0.24-0.28%, and the rest are Fe and unavoidable impurities.

[0044] The preparation method comprises the following steps:

[0045] (1) Allocation of raw materials: Determine the ingredients of raw materials such as 45 steel, pig iron, ferrophosphorus, ferromanganese, ferroboron, ferrosilicon, and copper according to the above-mentioned cast iron composition ratio;

[0046] (2) Raw material smelting: In the smelting furnace, the prepared raw materials are smelted at 1500°C to obtain molten iron;

[0047] (3) Inoculation: Add the lanthanum-cerium double rare earth mixture before the ladle, and then pour the molten iron into the ladle for inoculation. The incubation time is about 10 minutes, and the temperature of the molten iron is 1450°C; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com