Sheet pile structure for supporting and enclosing shore

A technology of structural slabs and sheet piles, which is applied in sheet pile walls, foundation structure engineering, buildings, etc., can solve problems such as short life cycle, high energy consumption, and poor vertical bearing capacity, and achieve improved material performance indicators and overall The effect of simple structure and strong bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

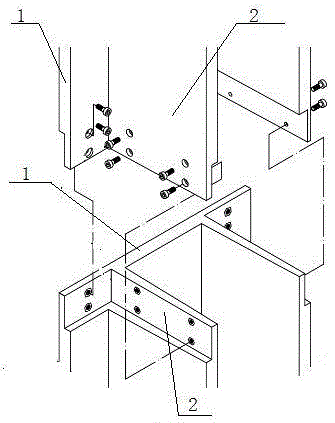

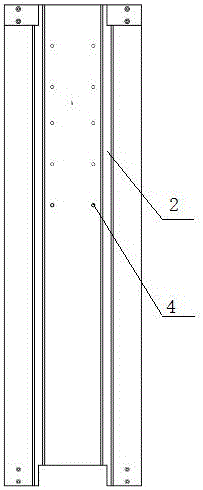

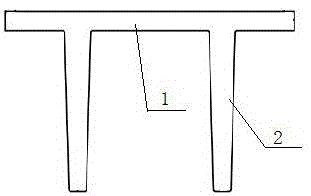

[0050] like figure 1 , 2 3. The inorganic high-performance thin-walled Π structural sheet piles for bank support and bank maintenance are composed of multiple Π structural sheet piles spliced horizontally and vertically. The Π structure is a sheet pile body 1 and two ribs 2, and the two ribs 2 are parallel to each other and perpendicular to the sheet pile body 1 to form a Π structure.

[0051] Further, the lateral splicing is that the sheet pile body is provided with a concavo-convex structure spliced with the laterally adjacent sheet pile bodies, such as Figure 5 The transverse concave-convex structure is open-shaped, and the left and right ends of the open-shaped structure are respectively provided with trapezoidal grooves and convex parts that match each other.

[0052] like Figure 4 , the longitudinal splicing is that both the sheet pile body and the rib are provided with a concavo-convex structure that is spliced with the longitudinally adjacent sheet pile body...

Embodiment 2

[0070] like Image 6 The horizontal concave-convex structure is a closed shape, and the left and right ends of the closed structure are respectively provided with dovetail-shaped grooves and convex parts that match each other. The shapes of the dovetail-shaped grooves and convex parts are trapezoidal at one end and round at the other end. shape. Other conditions are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com