Construction method for outer wall socket type plate buckle steel pipe scaffold

A socket-type, scaffolding technology, which is applied in the scaffolding supported by the house structure, the accessories of the scaffold, the structural support of the house, etc., can solve the problems of assembly and disassembly, reliability, safety, and economical insufficiency, and achieve high construction and dismantling Efficiency, good integrity, and guaranteed stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

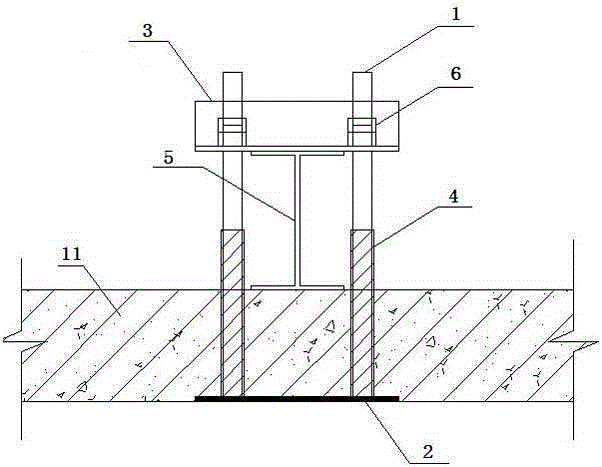

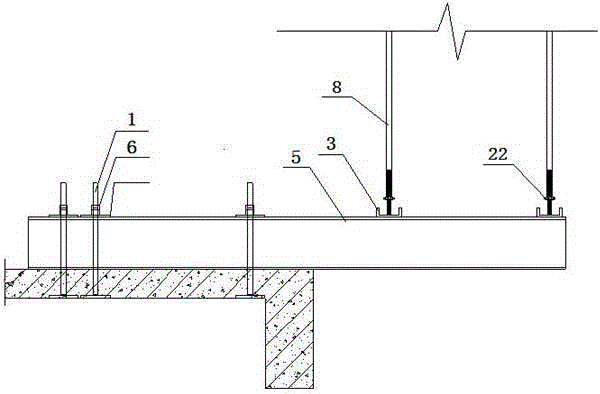

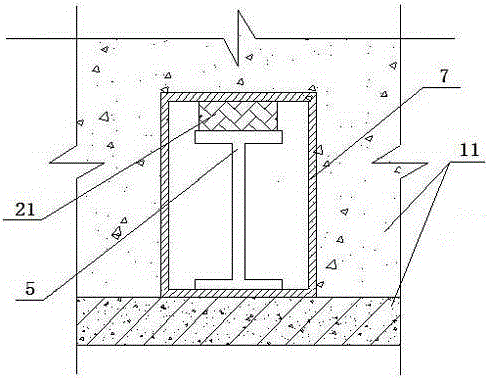

[0063] The construction method of the present invention takes 4 buildings with 18 floors as an example. Floor-mounted steel pipe fastener scaffolding is used for the outer wall scaffolding below the 3rd floor, and cantilevered socket-type buckle-type steel pipe scaffolding is used for the above 3rd floor, respectively on the 3rd, 9th, and 15th floors. Complete 3 overhangs. When the exterior wall scaffolding is erected, a buckle-type pressed-shaped steel pick-up plate is laid on each floor, and wooden boards are added to hard-isolate the steel overhang layer.

[0064] Such as Figure 6 and Figure 7 As shown, the specific construction method steps are as follows:

[0065] Step 1. Socket-type buckle-type outer frame erection parameters: the pole adopts Φ48×3.2 standard steel pipe; the step distance is 2.0m, the horizontal distance between the poles is 0.9m, the vertical distance is 0.9, 2.1m, and the wall pole is two steps and three spans , The number of working layers of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com