Drilling fluid recovery and solid control device

A drilling fluid and vacuuming device technology, applied in the field of oil drilling, can solve the problem that the mud recovery efficiency is difficult to meet the drilling construction and other problems, and achieve the effects of saving equipment purchase costs and maintenance costs, improving recovery rate, and improving screening efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] In this example, the upstream and downstream are distinguished by the flow direction of the drilling fluid. One end of the drilling fluid inflow is the upstream and the other end is the downstream.

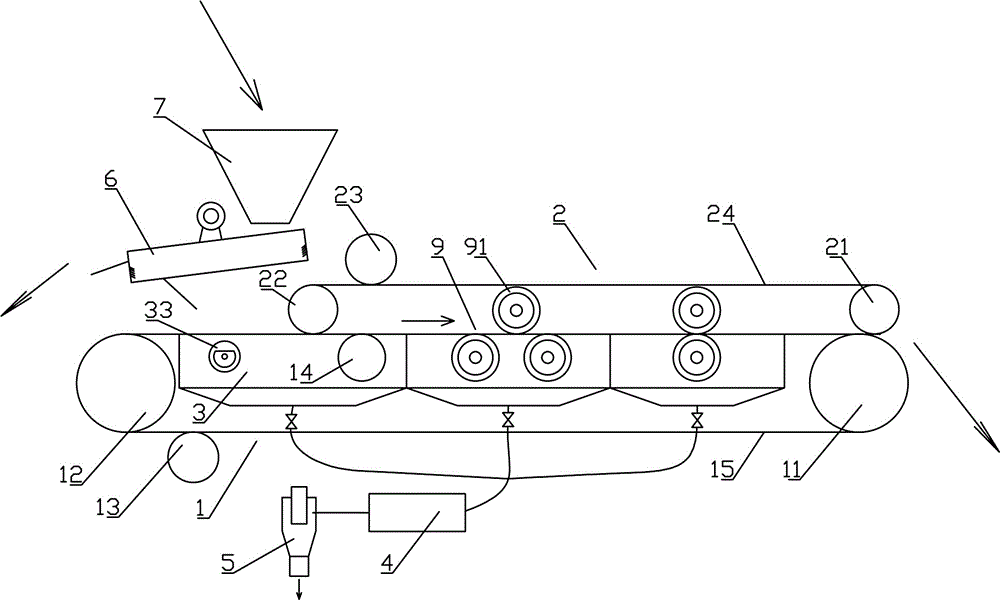

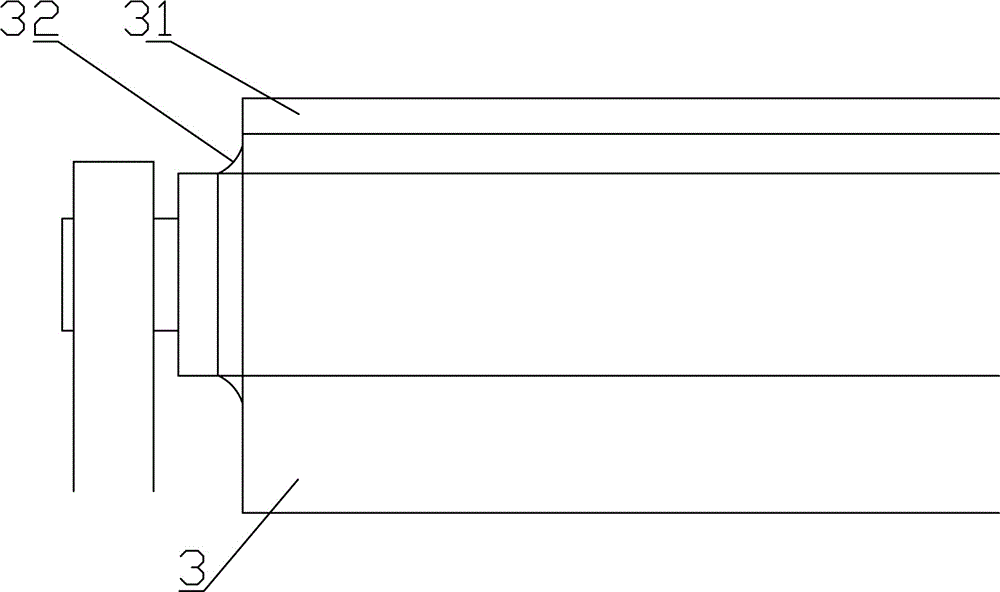

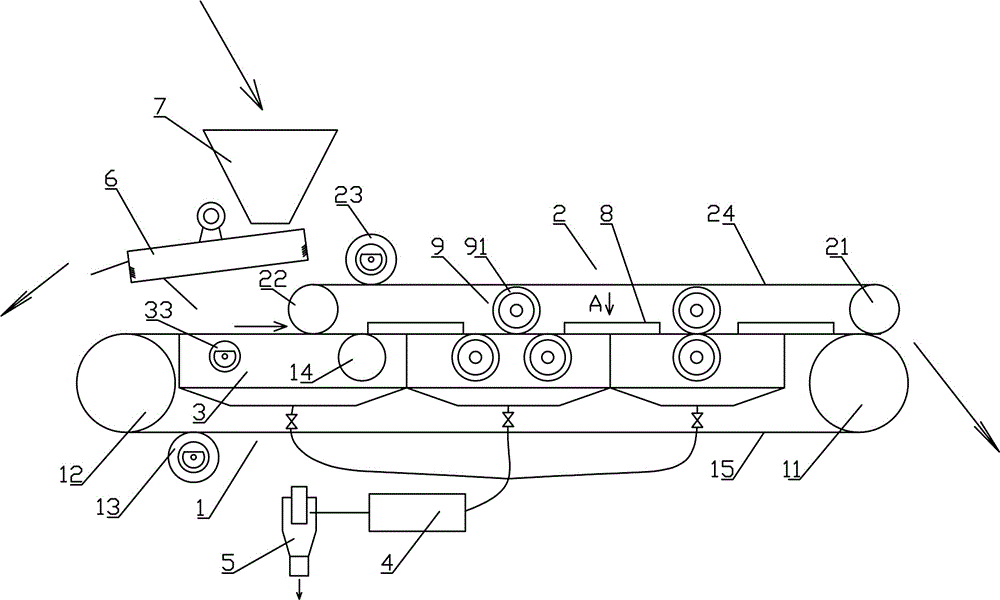

[0041] Such as figure 1 Among them, a solid control device for drilling fluid recovery, including a belt screen 1, in the belt screen 1, the belt screen 15 bypasses the belt screen driven roller 12 and the belt screen driven to rotate by the driving device The driving roller 11; the driving device is a commonly used motor, reducer and transmission mechanism, etc., which will not be described in detail here, and the driving device is not shown in the figure. Such as figure 1 , 3 Among them, the upper layer of the belt screen 15 of the belt screen 1 runs from left to right.

[0042] Such as figure 1 , 3 Among them, a belt pressing device 2 is provided above the belt screen 1;

[0043] In the described belt pressing device 2, the pressing belt 24 bypasses the belt pressi...

Embodiment 2

[0057] On the basis of Example 1, the preferred scheme is as figure 1 , 3 Among them, at least one negative pressure chamber 3 is provided under the upper layer of the belt screen 15, and the negative pressure chamber 3 is connected with the vacuum device 4. With this structure, when the drilling fluid enters between the upper layer of the belt screen 15 and the lower layer of the pressure belt 24, the vacuuming of the negative pressure chamber 3 can further improve the screening efficiency, especially suitable for high-mesh belt screens network.

[0058] preferred as figure 1 , 3 Among them, the diameter of the belt screen driving roller 11 is greater than the diameter of the pressing belt driving roller 22. With this structure, the volume of the whole device can be reduced, and it is convenient to arrange the negative pressure chamber 3 .

[0059] There are multiple negative pressure chambers 3, arranged along the upstream and downstream directions of the belt screen 15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com