Method for multistage sand prevention of ocean natural gas hydrate depressurization production

A technology for hydrate and natural gas, which is applied in the direction of production fluid, earthwork drilling, wellbore/well components, etc. It can solve the problems of production decline, increase of production pressure difference, and increase of sand control medium clogging, so as to improve the later production capacity, The effect of increasing the production pressure difference and increasing the production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

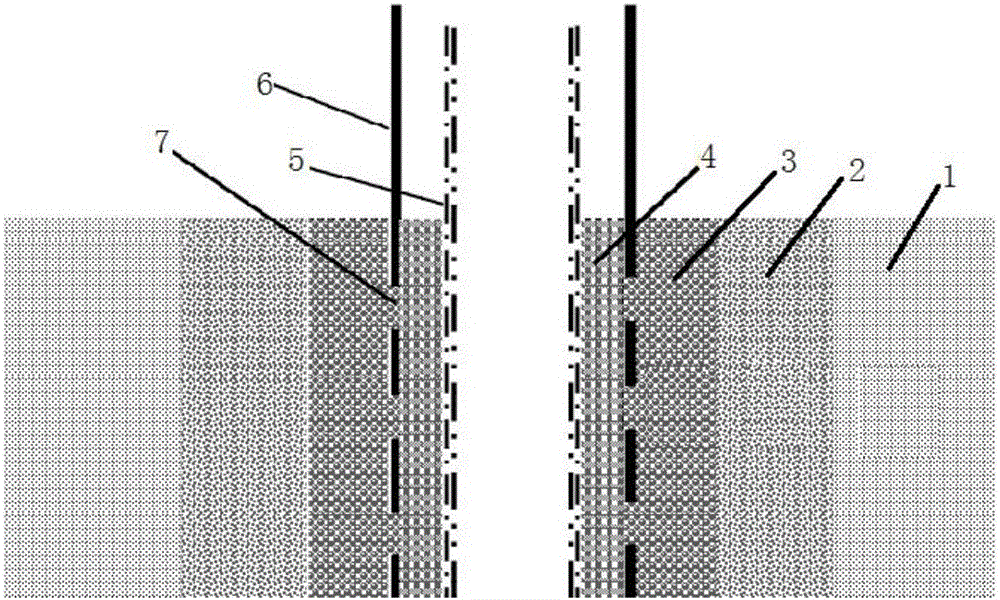

[0030] The concrete implementation of the present invention mainly comprises the following steps:

[0031] A sand control screen in a casing is a fourth-level sand retaining barrier; it is characterized in that it includes the following steps:

[0032] S1: Use low production differential pressure for decompression mining, monitor the particle size and sand content concentration of the produced sand through the online particle size analyzer, control the bottom hole flow pressure to be 0.5-2.5MPa lower than the hydrate phase equilibrium pressure, and decompose and recover the hydrate At the same time, the muddy and silty components near the wellbore are discharged, leaving only uniform sand with coarse particle size and good sorting coefficient in the formation near the wellbore outside the casing 6, forming a shale-removed coarse sand belt 2; when the wellhead dynamic When the sand production monitoring equipment monitors that the mud content drops below 0.3‰, the depressurizat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com