Pressure testing method for segmented oil pool and segmented trial-squeezing tubing string

A technology for reservoir pressure and testing methods, which is applied in the directions of measurement, earthwork drilling and production, cleaning equipment, etc., can solve problems such as lack of applicability, distortion of pressure measurement data, long construction period, etc., and achieve simple and fast calculation methods and reduce testing costs. Cycle, the effect of shortening the test cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

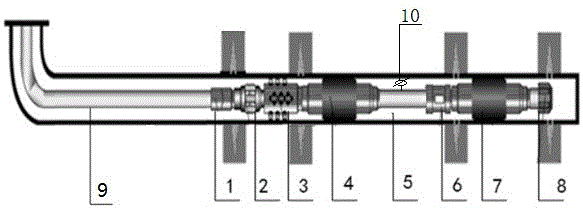

[0032] Such as figure 1 As shown, this embodiment provides a segmented test squeeze tubing string, including hydraulic anchor 3, Y111-type packer 4, tubing adjustment nipple 5, pressure-guiding sandblasting device 6, and Y211-type packer connected in series. The device 7, the guide 8, and the hydraulic anchor 3 are connected with the oil pipe 9 through the safety joint 1.

[0033] The segmented test squeeze tubing string mainly adopts the Y211+Y111 double-sealed single card test squeeze test integrated tubing string, which is set and unsealed by lifting the string up and down, which can not be affected by the construction displacement. Segment test extrusion, segmental pressure drop test can also be carried out.

[0034] The working process of the segmented test squeeze string is as follows: Step 1, connect the segmented test squeeze string to the tail of the tubing 9, and run the tubing 9 into the horizontal well so that the segmented test squeeze string is located at the fi...

Embodiment 2

[0044] Such as figure 1 As shown, a pressure gauge 10 is installed on the oil pipe adjustment sub-joint 5, and the pressure measurement by stopping the pump in step 3 can be performed by using an instrument truck or by using the pressure gauge 10 to record the bottom-hole pressure drop data;

[0045] A centralizer 2 is connected in series between the hydraulic anchor 3 and the tubing 9. The centralizer 2 is connected to the tubing 9 through a safety joint 1. The centralizer 2 can ensure the quality of drilling and cementing. In this embodiment, the specific protection is The position of the whole subsection test extrusion string does not deviate.

Embodiment 3

[0047] A segmented reservoir pressure testing method, comprising the steps of:

[0048] Step 1: Connect the segmental test squeeze tubing string to the tail of the oil tubing 9, and lower the tubing 9 into the horizontal well, so that the segmented test squeeze tubing string is located in the first fracturing section at the toe of the horizontal well to realize inter-stage isolation;

[0049] Step 2: Inject plugging-removing fluid into the first fracturing stage through the staged test squeezing tubing string, at a rate of 0-2m 3 / min displacement squeeze 15 ~ 30min;

[0050] Step 3: 1 to 2 minutes before the end of the squeeze, reduce the displacement step by step to zero, then stop the pump and measure the pressure for 1 to 2 hours, and use the instrument truck or pressure gauge 10 to record the bottom hole pressure drop data;

[0051] Step 4, lift up the segmented test extrusion tubing string to the next section, and repeat steps 2 and 3 to complete the second section of b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com