A kind of optical fiber humidity sensor based on tungsten disulfide and preparation method thereof

A technology of humidity sensor and tungsten disulfide, which is applied in instruments, scientific instruments, and material analysis through optical means, can solve problems such as complex structure, and achieve the effect of low production cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

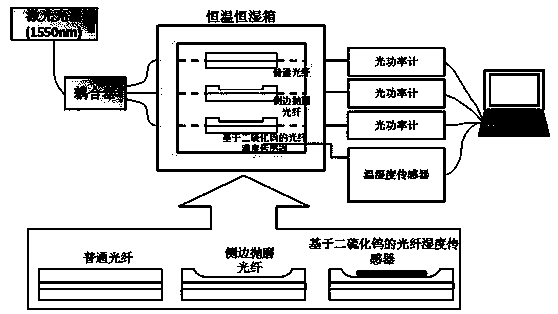

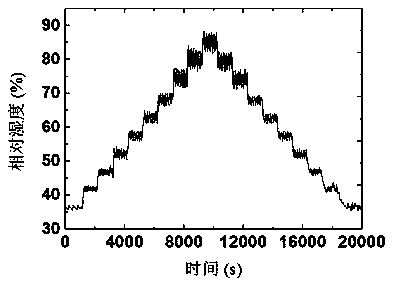

Method used

Image

Examples

Embodiment 1

[0033] A preparation method of an optical fiber humidity sensor based on tungsten disulfide, comprising the steps of:

[0034] S1. Preparation of side-polished single-mode optical fiber: by polishing, a part of the cladding and fiber core of the optical fiber is removed to form a flat area of a certain length on the surface of the optical fiber, that is, the polishing area; the polishing of the side-polished optical fiber The remaining depth of the grinding surface is 61μm (a part of the fiber core is polished off), and the length of the polishing area is 13.5mm;

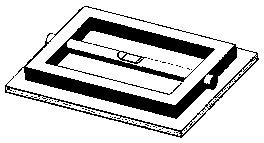

[0035] S2, deposition of tungsten disulfide film layer: as figure 1 , use UV glue to fix the side polished part on the glass slide, with the polished side facing up, then use UV glue to make a groove around the polished area, the size of the groove is 2×0.5×0.1cm 3 , drop the tungsten disulfide dispersion into the tank, place it at room temperature, wait until the water and alcohol evaporate naturally, and form ...

Embodiment 2

[0049] A preparation method of an optical fiber humidity sensor based on tungsten disulfide, comprising the steps of:

[0050] S1. Preparation of side-polished single-mode optical fiber: by polishing, a part of the cladding and fiber core of the optical fiber is removed to form a flat area of a certain length on the surface of the optical fiber, that is, the polishing area; the polishing of the side-polished optical fiber The remaining depth of the grinding surface is 70μm (a part of the fiber core is polished off), and the length of the polishing area is 5mm;

[0051] S2. Deposit tungsten disulfide film layer: Use UV glue to fix the side polishing part on the glass slide, with the polishing side facing up, and then use UV glue to make a groove around the polishing area, the size of the groove is 2×0.5× 0.1cm 3 , drop the tungsten disulfide dispersion into the tank, place it at room temperature, wait until the water and alcohol evaporate naturally, and form a tungsten disu...

Embodiment 3

[0055] A preparation method of an optical fiber humidity sensor based on tungsten disulfide, comprising the steps of:

[0056] S1. Preparation of side-polished multimode optical fiber: remove part of the cladding and fiber core of the fiber by polishing, and form a flat area of a certain length on the surface of the fiber, that is, the polishing area; the polishing surface is 1.5 μm away from the fiber core , the length of the polishing area is 30mm;

[0057] S2. Deposit tungsten disulfide film layer: Use UV glue to fix the side polishing part on the glass slide, with the polishing side facing up, and then use UV glue to make a groove around the polishing area, the size of the groove is 3×2× 0.5cm 3 , drop the tungsten disulfide dispersion into the tank, place it at room temperature, wait until the water and alcohol evaporate naturally, and form a tungsten disulfide film on the polishing area.

[0058] The tungsten disulfide dispersion is prepared by uniformly dispersing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com