Thermotechnical high-precision temperature measurement relay

A relay, high-precision technology, applied in relays, electromagnetic relays, electromagnetic relay details and other directions, can solve the problems of reduced accuracy, affected work, and reduced accuracy of temperature sensors at high temperature, to improve accuracy, avoid accuracy decline, avoid damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

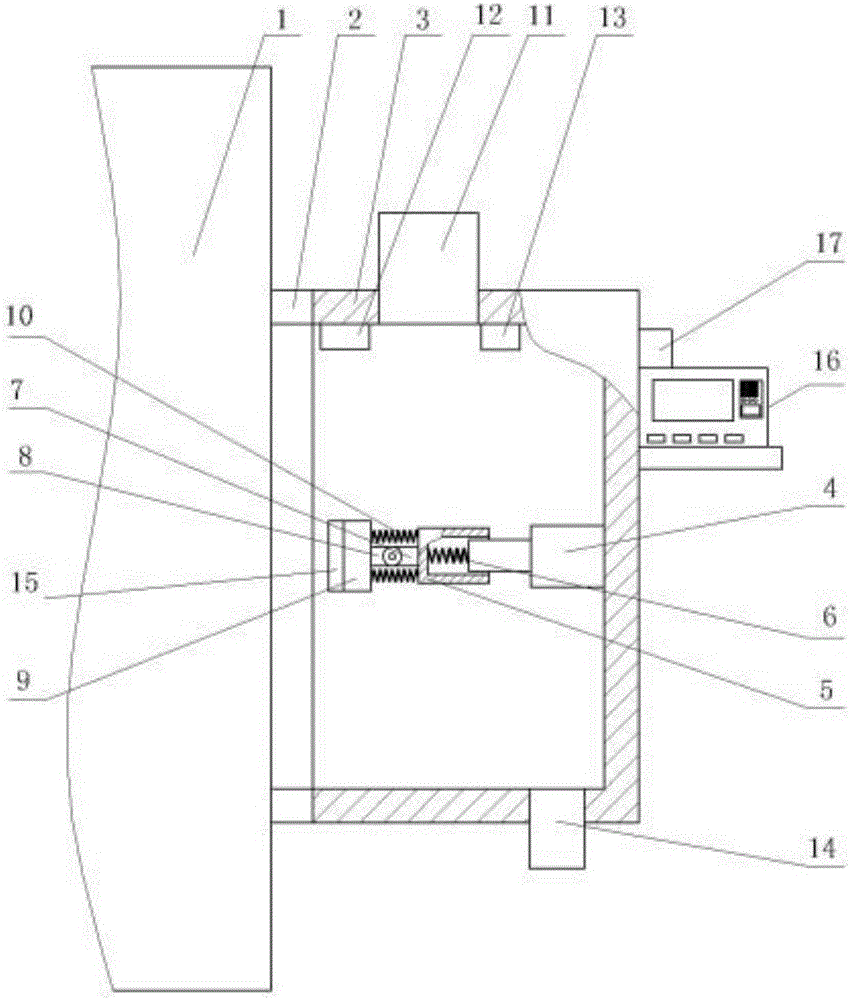

[0021] High-precision temperature measuring relays for thermal work, such as figure 1 As shown, it includes a relay body 1 and a temperature measuring device, wherein the temperature measuring device is installed on the side of the relay body 1, and the temperature measuring device includes a fixed shell 3, a push rod motor 4, a fixed tube 5, a first spring 6, a second A fixed rod 7, a second fixed rod 8, a pressure sensor 9, a second spring 10, a fan 11, a first temperature sensor 12, a humidity sensor 13, a one-way valve 14, a second temperature sensor 15, a control device 16 and an alarm 17. The fixed shell 3 is a shell with an opening on one side, and the openin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com