Semiconductor and fabrication method thereof

A technology for semiconductors and devices, applied in the field of semiconductor devices and their preparation, can solve the problems that the source and drain regions need to be sufficiently large and small.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

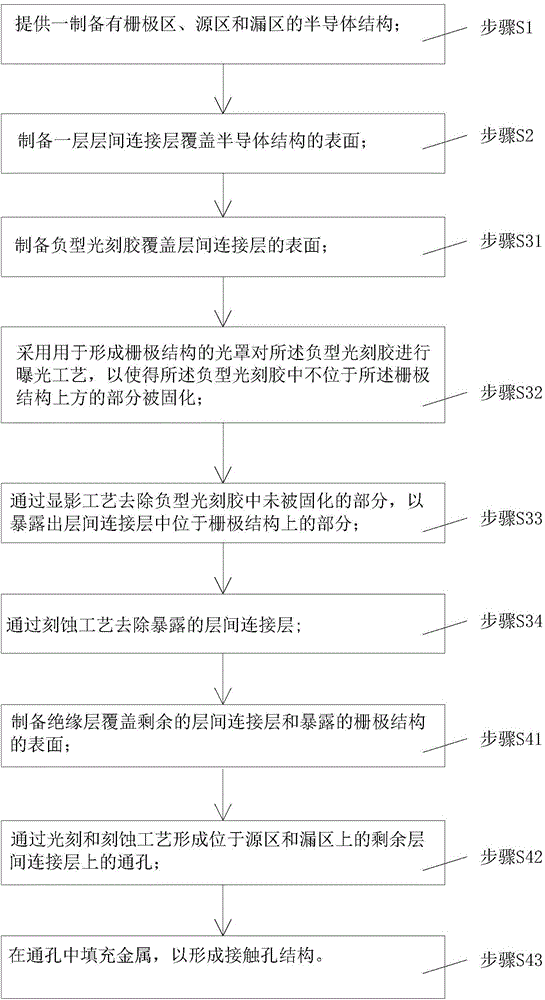

[0049] The preparation method of interlayer connecting layer of the present invention mainly comprises the following steps:

[0050] Step S1, providing a semiconductor structure prepared with a gate structure, a source region and a drain region;

[0051] Step S2, preparing a layer of interlayer connection layer covering the surface of the semiconductor structure;

[0052] Step S3, removing the interlayer connection layer covering the gate structure;

[0053] Step S4 , continuing to prepare a contact hole structure on the remaining interlayer connection layer located on the source region and the drain region.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com