Metal capacitor structure and preparation method thereof

A metal capacitor and capacitor structure technology, applied in capacitors, circuits, electrical components, etc., can solve the problems of chip failure, easy breakdown of metal capacitor structures, poor reliability, etc., and achieve the effect of improving the breakdown voltage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

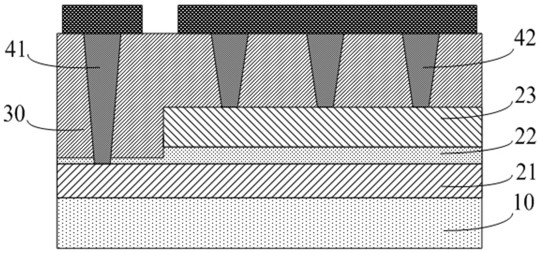

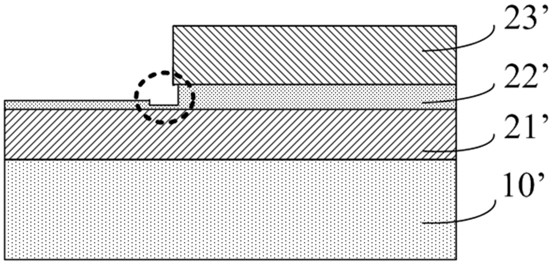

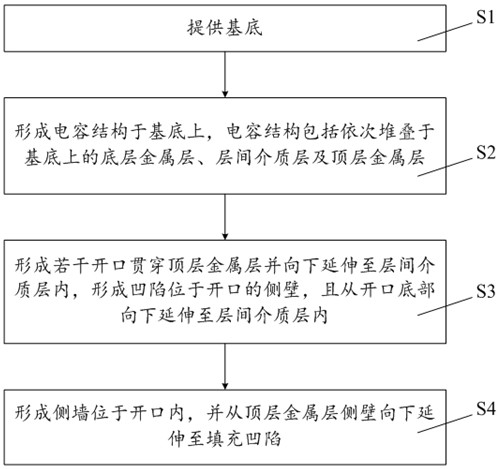

[0038] figure 2 It is a schematic cross-sectional view of forming a depression in the preparation method of the metal capacitor structure. Please refer to figure 2 , a bottom metal layer 21', an interlayer dielectric layer 22' and a top metal layer 23' are formed on the substrate 10', since the interlayer dielectric layer 22' determines the capacitance value of the metal capacitance structure, if the interlayer dielectric layer 22' If the defect density is low, the breakdown voltage of the metal capacitor structure is mainly limited by the etching of the top metal layer 23 ′. During the fabrication of the metal capacitor structure, it is necessary to use a patterned photoresist layer (not shown in the figure) as a mask to etch the top metal layer 23' to form an opening through the top metal layer 23', which exposes the interlayer The surface of the dielectric layer 22'. However, in order to completely remove the top layer metal layer 23' in the opening without residue, ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com