Fabrication method of holographic speckle structured organic light emitting diode

A technology of light-emitting diodes and a manufacturing method, which is applied in the fields of semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of difficult control of groove depth of nano moth-eye structure, increased leakage current, dispersion band, etc., and achieves improved dispersion. and spectral drift phenomenon, the effect of directional enhancement of light

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Embodiment 1: The angle between the speckle object light and the reference light is 45 degrees.

[0043] The technical solution of the present invention will be clearly and completely described below in conjunction with the accompanying drawings and specific implementation methods. Obviously, the described embodiments are only some of the embodiments of the present invention, not all of them. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

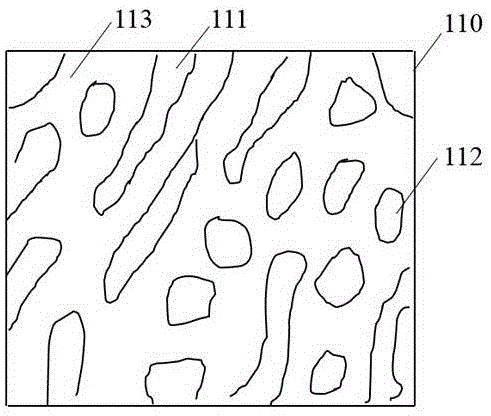

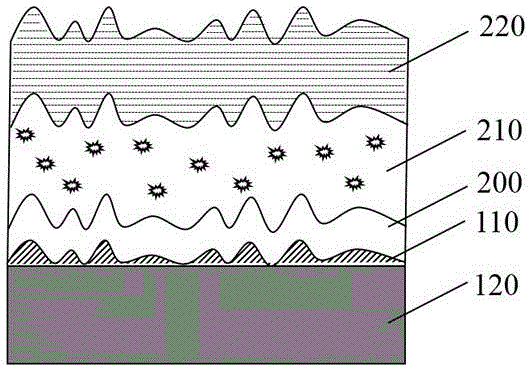

[0044] The invention discloses a method for manufacturing an organic light-emitting diode with a speckle structure. join figure 1 As shown, the speckle structure 110 includes quasi-randomly distributed striped grooves 111 , quasi-randomly distributed speckled pits 112 and quasi-randomly distributed raised stripes 113 .

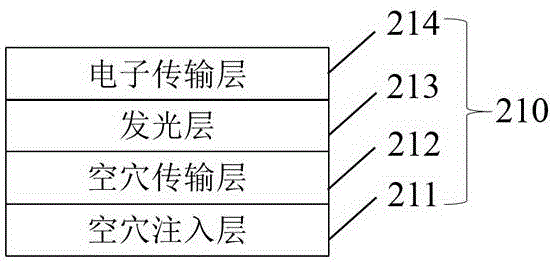

[0045] see figure 2 and image 3 As mentioned a...

Embodiment 2

[0069] Embodiment 2: The angle between the speckle object light and the reference light is 30 degrees.

[0070] In Embodiment 2, the angle between the speckle object light and the reference light is 30 degrees, and all other process steps and parameters are completely the same as in Embodiment 1. see Figure 11 , the test results show that within the range of 60-degree and 120-degree field of view, the light extraction efficiency of the present invention is directionally increased by 200%, and the 60-degree directional enhancement of the field of view is agreed to be due to the holographic speckle reproduction of positive and negative first-order images. It is also twice the angle of 30 degrees between the speckle object light and the reference light. It shows that the present invention can realize the enhancement of OLED directional light output by adjusting the angle between the speckle object light and the reference light.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com