Electrode terminal and preparation method thereof, battery cover board assembly, battery, battery bank, battery pack and electric vehicle

An electrode terminal and battery cover technology, which is applied in electric vehicles, battery pack parts, electrical components, etc., can solve the problems of poor connection reliability and difficult welding, and can ensure the overcurrent capacity and connection strength, and ensure the connection reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] This embodiment is used to illustrate the method for preparing an electrode terminal provided by the present invention.

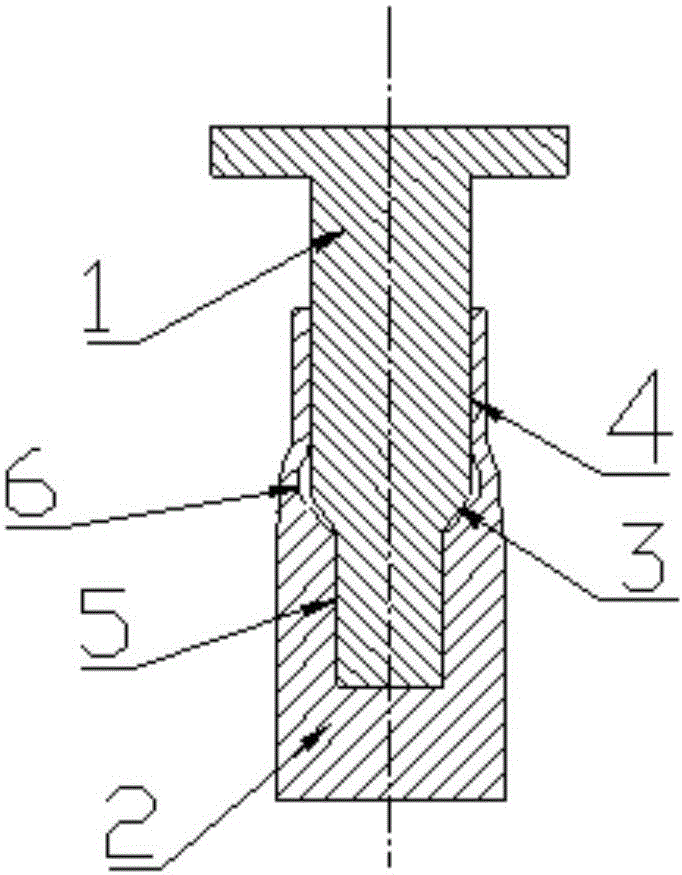

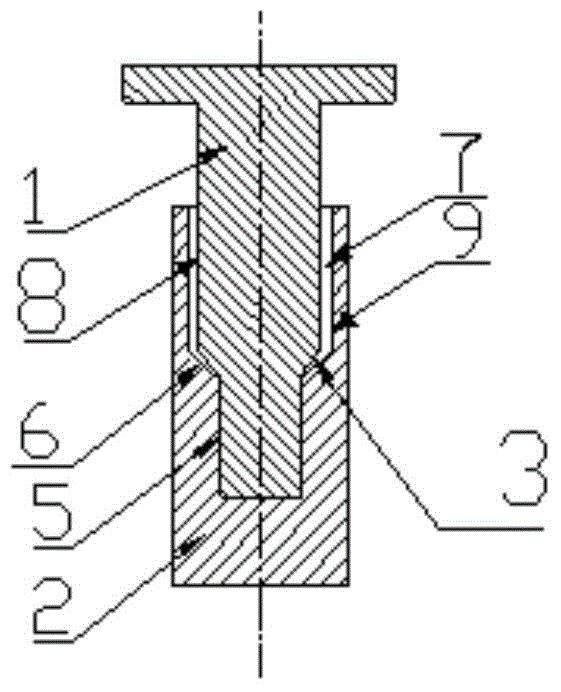

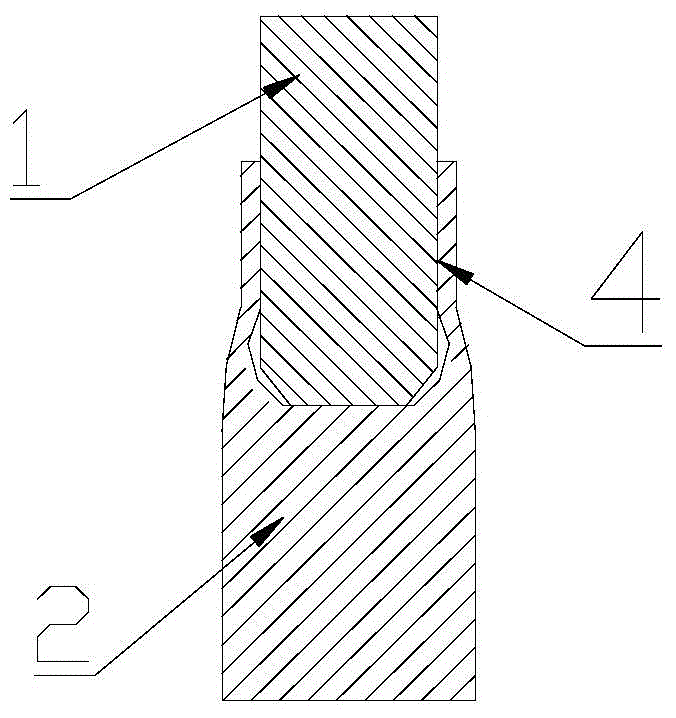

[0050] Such as figure 2 As shown, the connector: the outer diameter of the positioning pin is 5.03mm, the length of the positioning pin is 6mm, the height of the transition zone is 5mm, the diameter of the outer connection area of the insertion end is 10mm, and the length of the outer connection area of the insertion end is 10mm; Terminal: The diameter of the mating area is 5.00mm, the depth of the mating area is 6cm, and the diameter of the inner connection area of the socket is 12mm. Wherein, the depth of the interference region between the outer diameter of the positioning pin and the inner diameter of the matching area is 5 mm, and the interference amount is 0.03 mm.

[0051] Insert the positioning pin into the mating area, the gap between the outer connection area and the inner connection area is 1.5mm, perform electromagnetic pulse weld...

Embodiment 2

[0054] This embodiment is used to illustrate the method for preparing an electrode terminal provided by the present invention.

[0055] Such as figure 2 As shown, the connector: the outer diameter of the positioning pin is 3.00mm, the length of the positioning pin is 8mm, the height of the transition zone is 3mm, the diameter of the outer connection area of the insertion end is 8mm, and the length of the outer connection area of the insertion end is 15mm; Terminal: The diameter of the mating area is 3.04mm, the depth of the mating area is 10cm, and the diameter of the inner connection area of the socket is 9mm. Wherein, the depth of the interference area between the outer diameter of the positioning pin and the inner diameter of the matching area is 3 mm, and the interference amount is 0.04 mm. The outer connection area of the connector is parallel to the axis, and the inner connection area and the outer connection area form an included angle of 9°.

[0056] Insert ...

Embodiment 3

[0059] This embodiment is used to illustrate the method for preparing an electrode terminal provided by the present invention.

[0060] Such as figure 2 As shown, the connector: the outer diameter of the positioning pin is 8.05mm, the length of the positioning pin is 15mm, the height of the transition zone is 5mm, the diameter of the outer connection area of the insertion end is 8mm, and the length of the outer connection area of the insertion end is 20mm; Terminal: The diameter of the mating area is 8mm, the depth of the mating area is 10cm, and the diameter of the inner connection area of the socket is 20mm. Wherein, the depth of the interference region between the outer diameter of the positioning pin and the inner diameter of the matching area is 10 mm, and the interference amount is 0.08 mm. The outer connection area of the connector is parallel to the axis, and the inner connection area and the outer connection area form an included angle of 15°.

[0061] Inse...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com