Colloidal graphite grounding electrode

A technology of colloidal graphite and grounding electrodes, applied in the direction of connecting contact materials, etc., can solve the problems of loss of lightning protection, small graphite grounding surface, and inability to withstand huge lightning currents, etc., to achieve long validity period, small contact resistance, and stable grounding resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

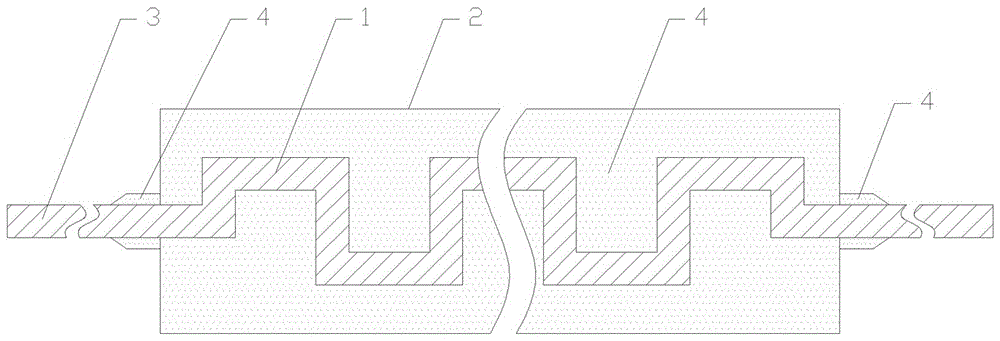

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

[0017] Such as figure 1 Shown: a colloidal graphite ground electrode, including a graphite soft rope 1, is characterized in that: the graphite soft rope 1 is installed in a colloidal graphite block 2, and two ends extend out to be used for connecting the connecting end 3 of the circuit, the described The colloidal graphite block 2 is in an elongated block structure. The colloidal graphite block 2 is formed by mixing and solidifying colloidal graphite 4 and water. The graphite soft rope 1 is in a coiled state in the colloidal graphite block 2, so that the voltage uniform delivery,

[0018] A layer of colloidal graphite 4 is evenly coated on the contact portion between the connecting end 3 and the colloidal graphite block 2 for strengthening the graphite soft rope 1 .

[0019] The colloidal graphite block 2 is formed by mixing and solidifying colloidal graphite 4 and o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com