Embroidered instep process and instep applying same

A technology for embroidering shoes and shoe uppers, applied in the mechanism, application, embroidery machine and other directions of embroidery machines, can solve the problems of human health threat, troublesome production process, insufficient comfort, etc., and achieve more flexible production, save labor costs, Good stereo effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

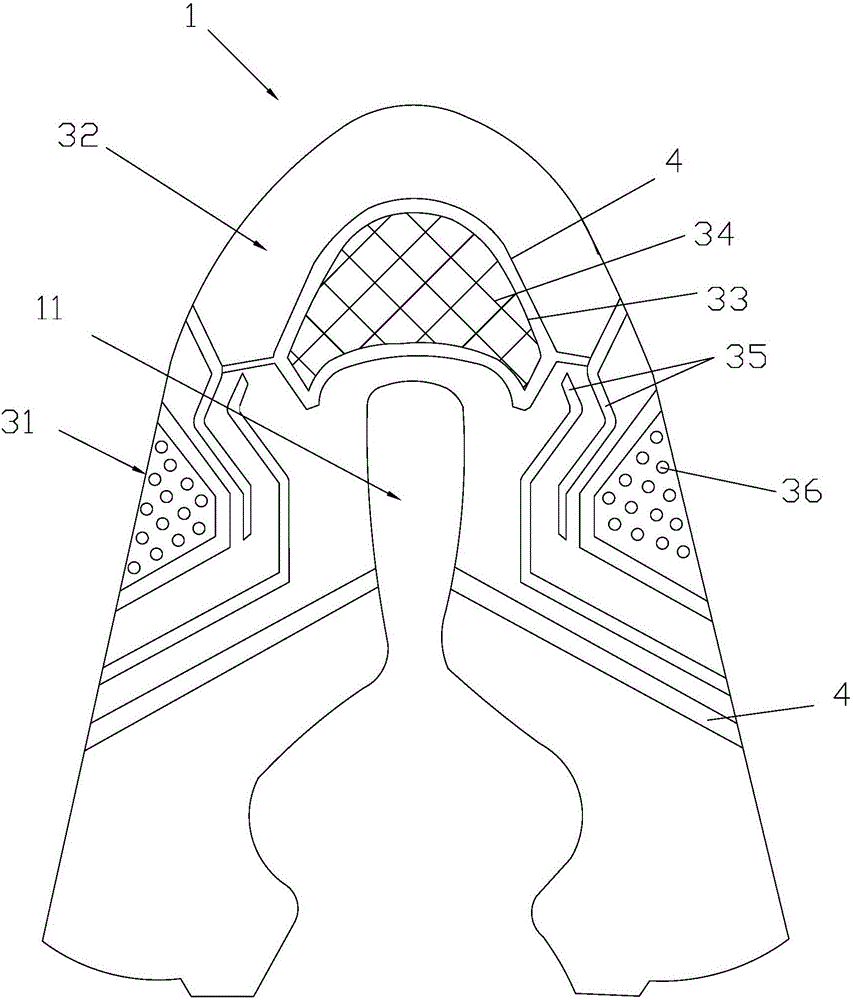

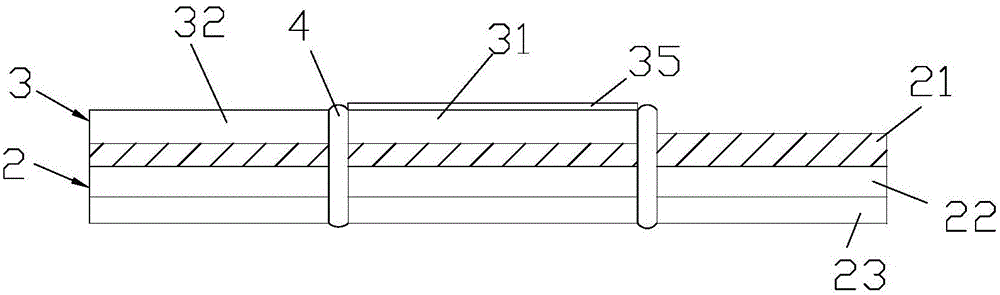

[0020] Such as figure 1 with figure 2 As shown, an embroidered vamp process includes the following steps: (1) designing the vamp by computer to make artwork; (2) according to the design artwork in step (1), cutting different fabrics into shoe vamps by laser machine The splicing parts 3 of the base cloth 2 and the upper; (3) typesetting the splicing parts 3 cut in step (2) on the base cloth 2, and then according to the embroidery thread texture of the artwork, the splicing parts 3 of the upper are passed through the embroidery machine. The splicing part 3 is embroidered on the base cloth 2; (4) the redundant base cloth 2 of the upper is cut along the edge of the splicing part 3 by a laser machine again to form the upper of the finished shoe shape.

[0021] The process is greatly simplified, the production efficiency is improved, and labor costs are saved, and various fabrics with different properties can be used for production according to requirements. The product production...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com