Denture engraving fixture applicable to club-shaped materials

A rod-shaped material and denture technology, which is applied in medical science, dentistry, dental prosthesis, etc., can solve the problems of low precision and complex structure of dentures, and achieve the effect of improving processing efficiency and ensuring processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

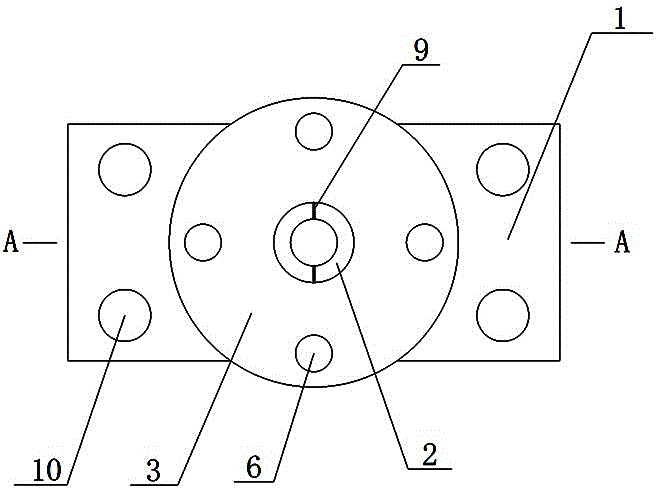

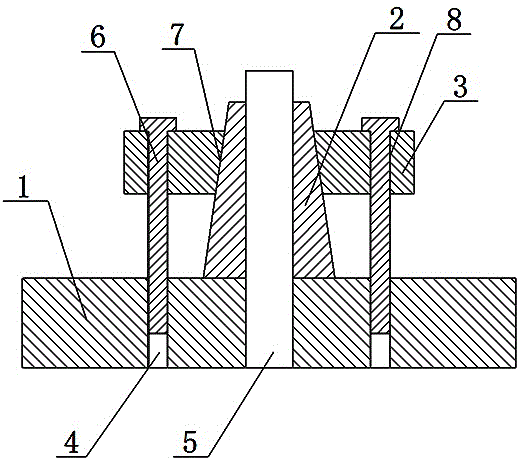

[0013] The present invention will be further described below in conjunction with the accompanying drawings, and the protection scope of the present invention is not limited to the following:

[0014] like figure 1 and figure 2 As shown, a denture carving fixture suitable for rod-shaped materials includes a base 1, a conical collet 2, and a locking disc 3. The middle of the base 1 is provided with a feeding hole 5, and the conical collet 2 is fixedly installed on the base 1, the hollow part inside the conical collet 2 is used to install the denture material, and the axis line of the hollow part coincides with the axis line of the feeding hole 5, therefore, during processing , insert the titanium rod into the conical chuck 2 from the feeding hole 5. After the denture is processed, remove it, and after the end face is flattened, the titanium rod is pushed up, and the next processing can be performed, so that the same The titanium rod is processed for many times, and the conica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com