Digital controlled lathe capable of conducting automatic loading and suitable for shaft parts

An automatic feeding and CNC lathe technology, applied in the field of mechanical parts processing, can solve the problems of low feeding efficiency, prone to material jams, complex structure, etc., and achieve the effect of automatic feeding and feeding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

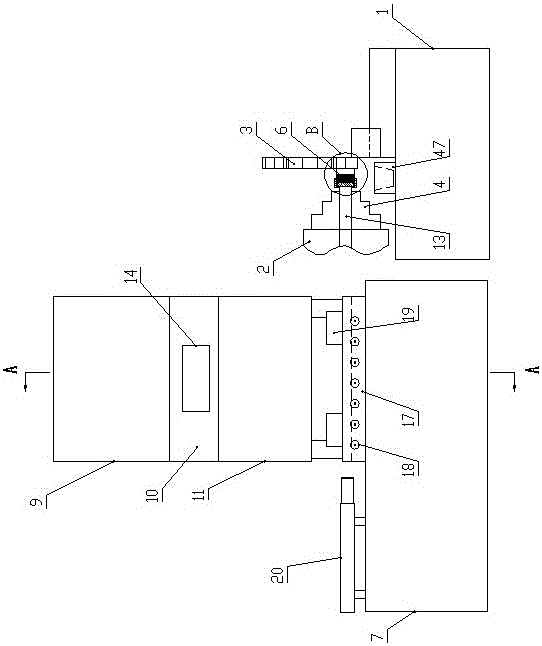

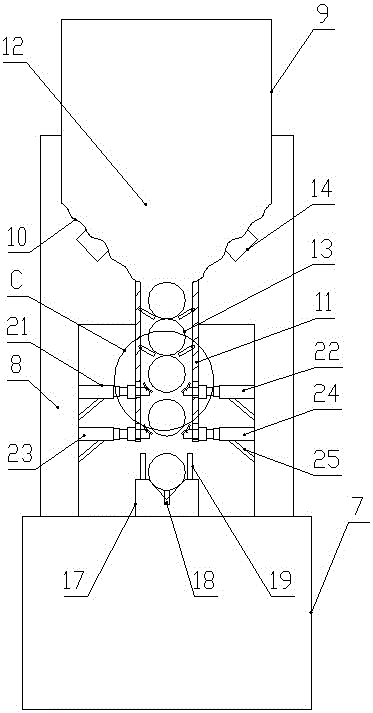

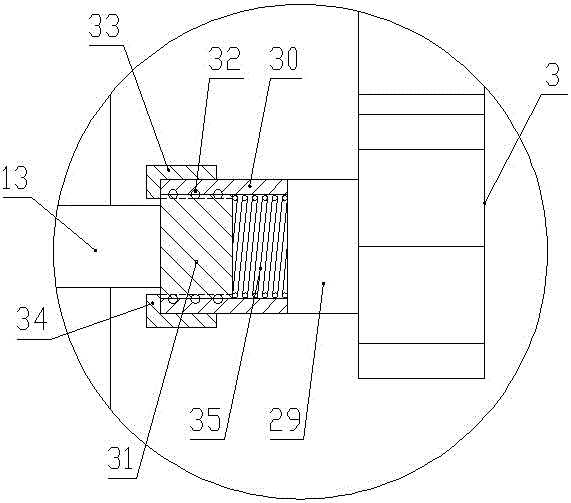

[0018] Such as Figure 1-4 As shown, an automatic feeding numerical control lathe suitable for shaft parts of the present invention includes a lathe body 1. A hollow spindle 2 is arranged on the lathe body 1, and the hollow spindle 2 is arranged in a horizontal direction in the front and rear directions. There is a slide rail in the horizontal direction, a tool holder 3 is slid on the slide rail, a hollow chuck 4 is fixedly connected to the front end of the hollow spindle 2 coaxially, and a cutting mechanism 5 and an electromagnetic adsorption mechanism 6 are provided on the tool holder 3. Electromagnetic adsorption mechanism 6 is located directly in front of the hollow chuck 4, and an automatic feeding device is provided behind the lathe body 1; the automatic feeding device includes a bin base 7, which is fixedly connected with a bin bracket 8, and the automatic feeding device The storage box 9, the bellows expansion joint 10 and the lowering box 11 are fixedly connected from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com