Mechanical structure of humanoid edge climbing line patrol robot and obstacle crossing method thereof

A line inspection robot and mechanical structure technology, applied in the field of robots, can solve the problems of inability to achieve continuous inspection of ultra-high voltage transmission lines, obstacles or drainage lines that cannot be crossed, etc., and achieve the effect of reducing labor intensity and reducing operating costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

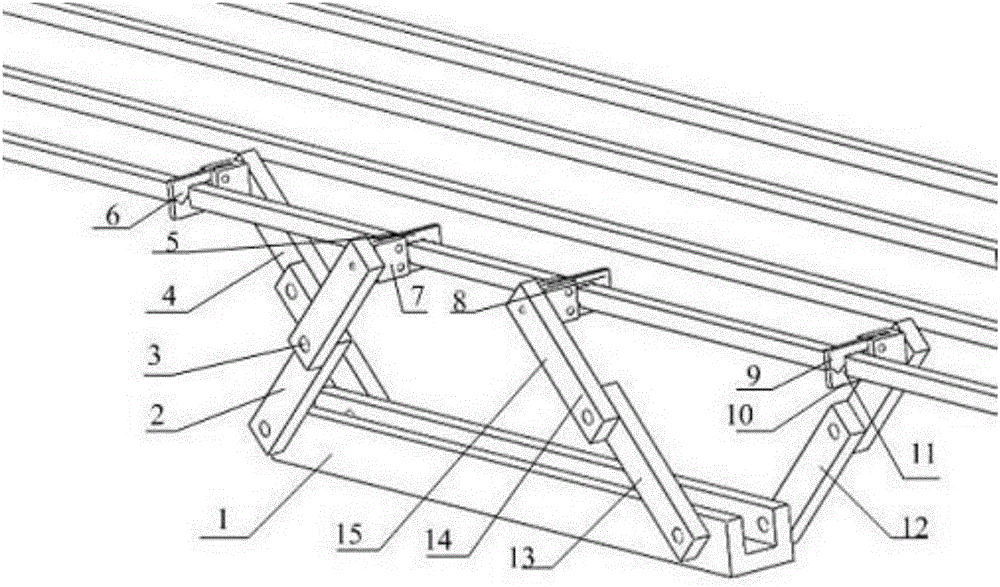

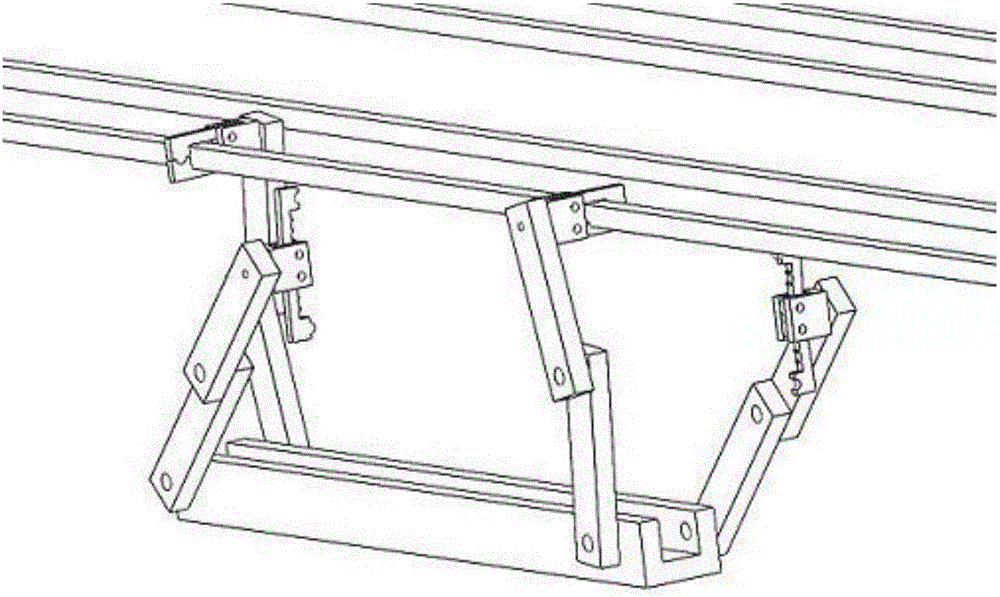

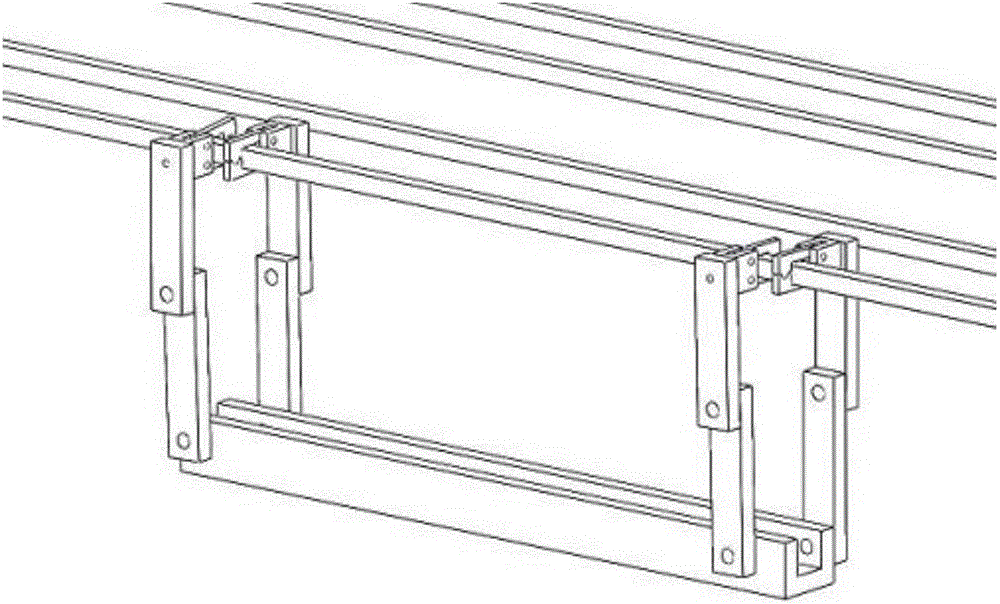

[0029] On the one hand, the present invention provides a mechanical structure of a humanoid climbing type line inspection robot, such as figure 1 shown, including rack 1, where:

[0030] The four corners of the frame 1 are respectively provided with a first mechanical arm 2 , a second mechanical arm 4 , a third mechanical arm 12 and a fourth mechanical arm 14 which can flex and extend forward and backward along the walking direction of the frame 1 ;

[0031] The first manipulator 2, the second manipulator 4, the third manipulator 12 and the fourth manipulator 14 are respectively provided with the first manipulator 5, the second manipulator 6, the third manipulator 11 and the The fourth manipulator 8;

[0032] A rotatable mechanical wrist 7 is arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com