Multi-axle distributed driving pure electric vehicle seriation platform

A technology of pure electric vehicles and electric buses, which is applied in the direction of electric power devices, power devices, vehicle components, etc., can solve the problems of small load mass, large unsprung mass, and limited use, so as to reduce manufacturing difficulty and cost, drive Small slip ratio and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

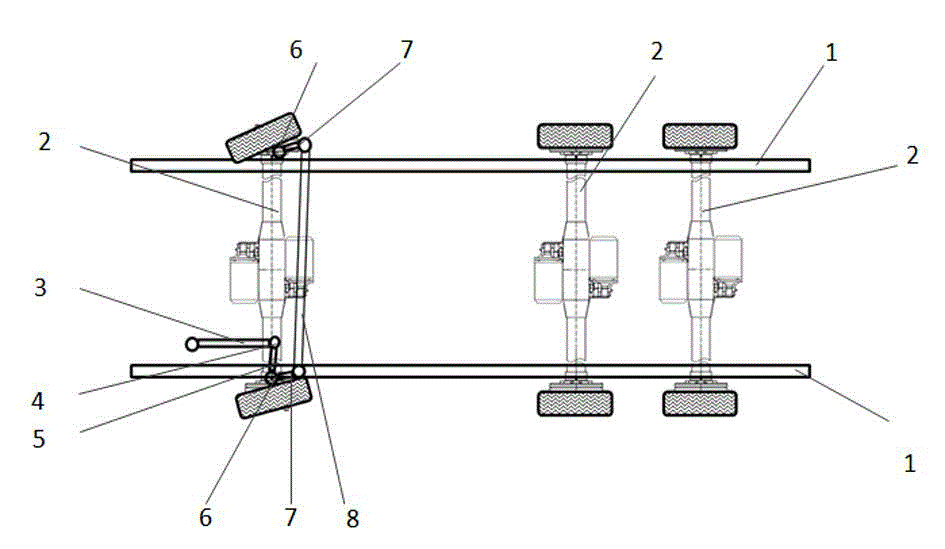

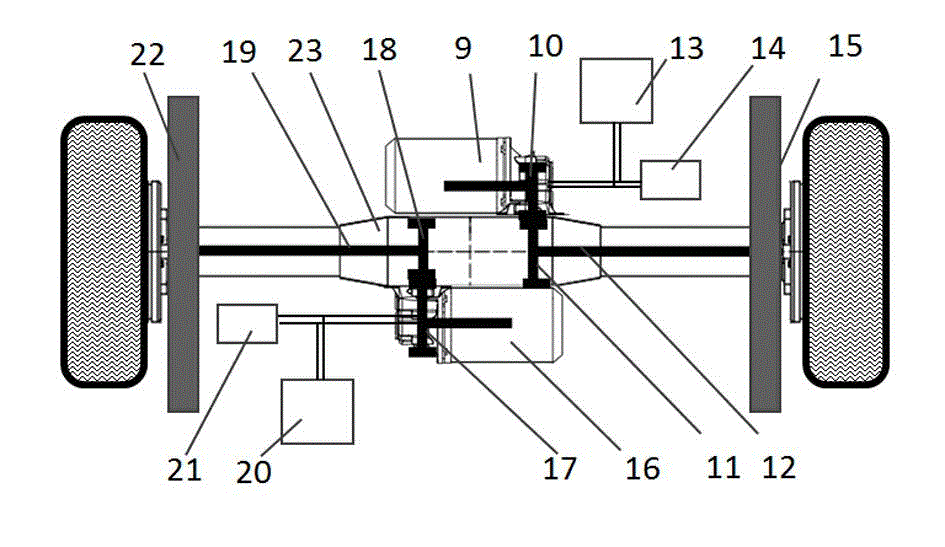

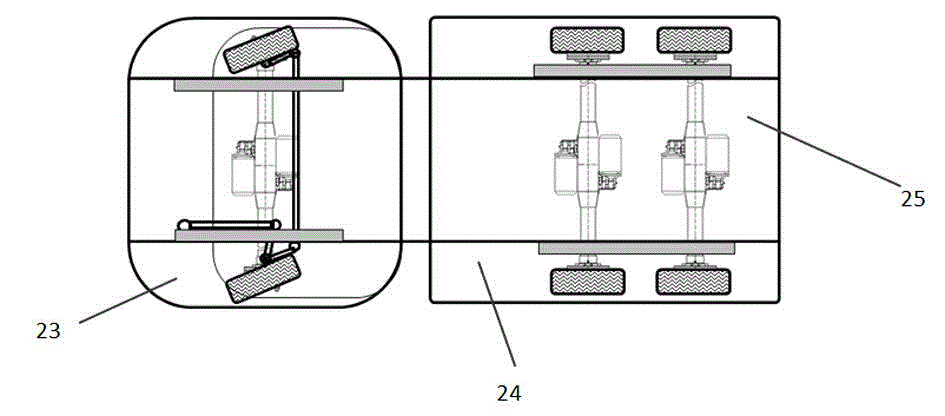

[0030] A series platform for multi-axis distributed drive pure electric vehicles, including a frame and two or more double-motor drive axles arranged under the frame, specifically two-axis distributed drive chassis platforms assembled into 4×2 and 4×4 drive forms; three Axis distributed drive chassis platforms are assembled into 6×4, 6×6 drive forms; four-axis distributed drive chassis platforms are assembled into 8×4, 8×6, 8×8 drive forms. The front axle can also be designed as a non-drive axle, eventually forming a series platform for pure electric vehicles with M×N multi-axis distributed drive.

[0031] The two-axis distributed drive vehicle series platform is specifically divided into electric two-axis full-drive chassis platform (4×4) and electric two-axis single-drive chassis platform (4×2).

[0032] Three-axis distributed drive vehicle series platform, if the front axle is designed as a non-drive steering axle, and the rear four wheels are driven by two drive axles, a 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com