Production method and equipment for producing metatitanic acid through titanium dioxide slurry

A technology of production equipment and production methods, which is applied in chemical instruments and methods, titanium compounds, inorganic chemistry, etc., to achieve the effect of ensuring recovery rate, high efficiency and good sedimentation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

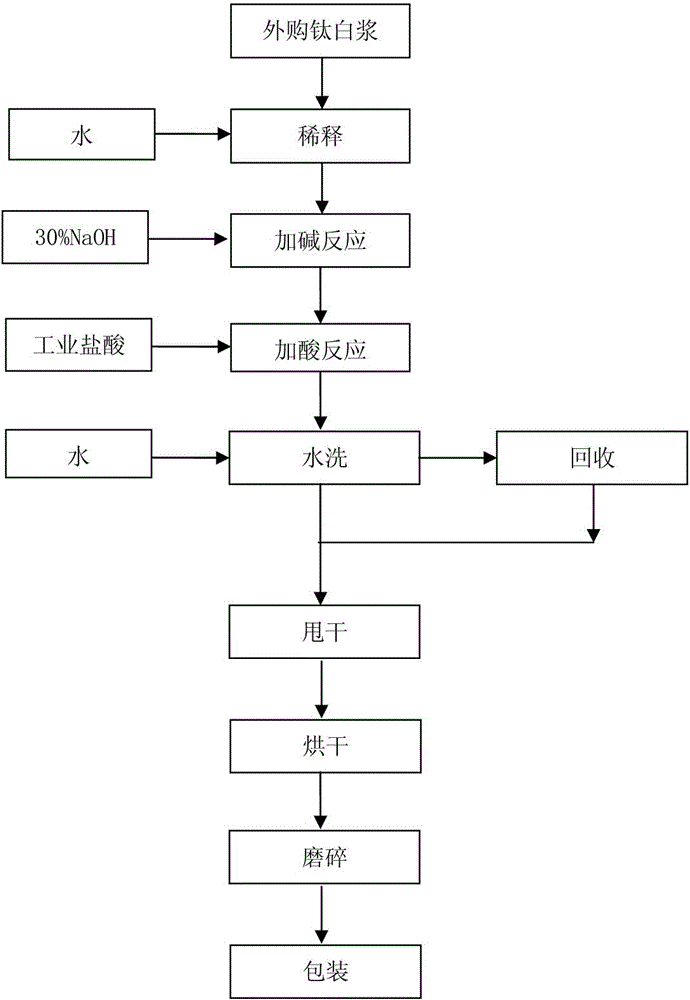

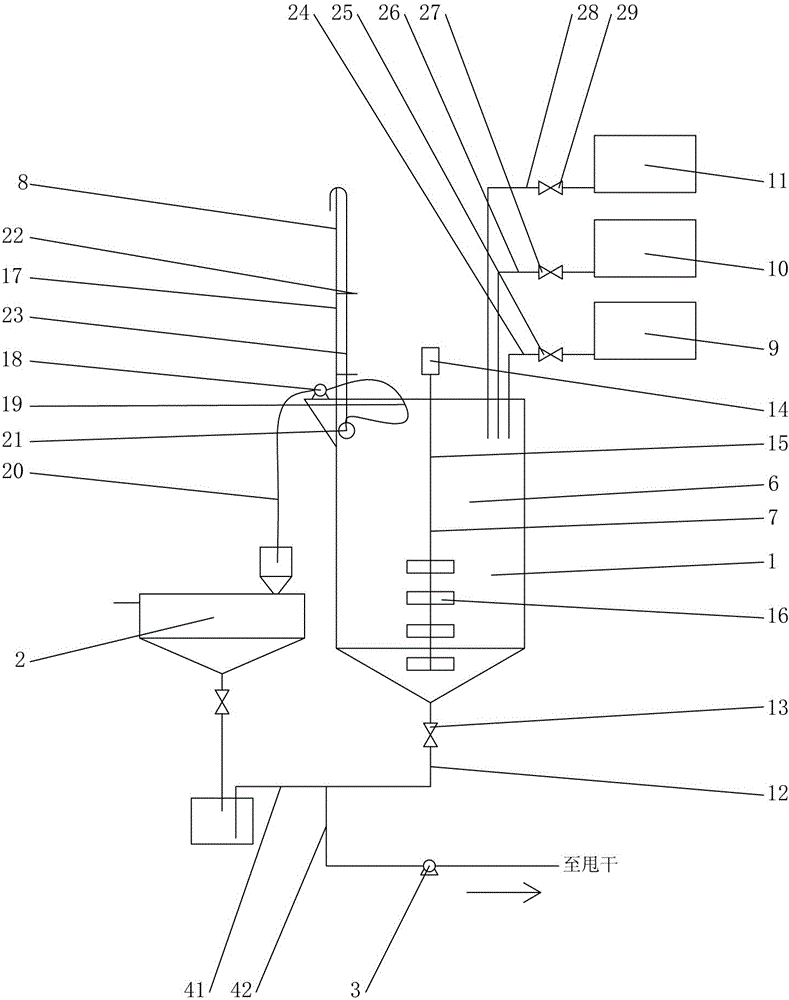

[0063] Such as Figure 1 to Figure 8 Shown, titanium white slurry produces metatitanic acid production method, and this method comprises the following steps:

[0064] A. Dilution: Put 700Kg of purchased titanium dioxide slurry into the washing tank 6, start the stirring device 7, open the water inlet valve 29, add 10 tons of water, and stir for 10 minutes;

[0065] B. Alkali addition reaction: open the lye valve 25 and add 30% NaOH solution, stir evenly to make the pH value reach 9-11, open the water inlet valve 29 and add 1500Kg water, stir for 10 minutes to clarify;

[0066] C, acid addition reaction: After 20-24 hours of precipitation, absorb the supernatant liquid with the liquid suction device 8, then start the stirring device 7, and open the acid liquid valve 27 during stirring to process industrial hydrochloric acid to make the pH value reach 5-7;

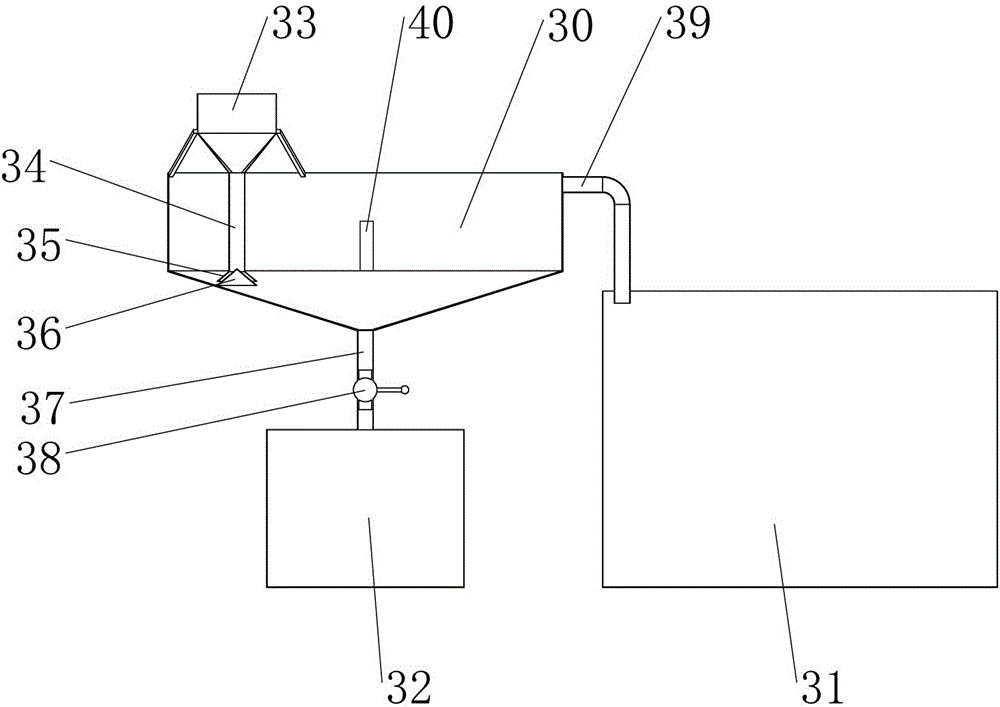

[0067] D. Water washing: Then open the water inlet valve 29 and add 2500Kg of water, stir for 10 minutes, clarify, after ...

Embodiment 2

[0089] Titanium white slurry produces the production method and equipment for metatitanic acid, and its embodiment is as embodiment 1, and difference is that the titanium white slurry that buys out is 750Kg, and described vertical tube and horizontal tube form the included angle of 90.6 °, and described turning The rotating speed is 500 rpm, and there are 8 serpentine cooling pipes.

Embodiment 3

[0091] Titanium white slurry produces the production method and equipment for metatitanic acid, and its embodiment is as embodiment 1, and difference is that the titanium white slurry that buys out is 800Kg, and described vertical tube and horizontal tube form the included angle of 90.6 °, and described rotating The rotating speed is 400 rpm, and there are 10 serpentine cooling pipes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com