Environment-friendly high-pressure water jet dedusting system

A high-pressure water jet and high-pressure water pump technology, applied in water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve groundwater or seawater pollution, waste of fresh water resources, air pollution and other problems , to achieve the effects of reducing wear and tear, achieving zero discharge, and avoiding water pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

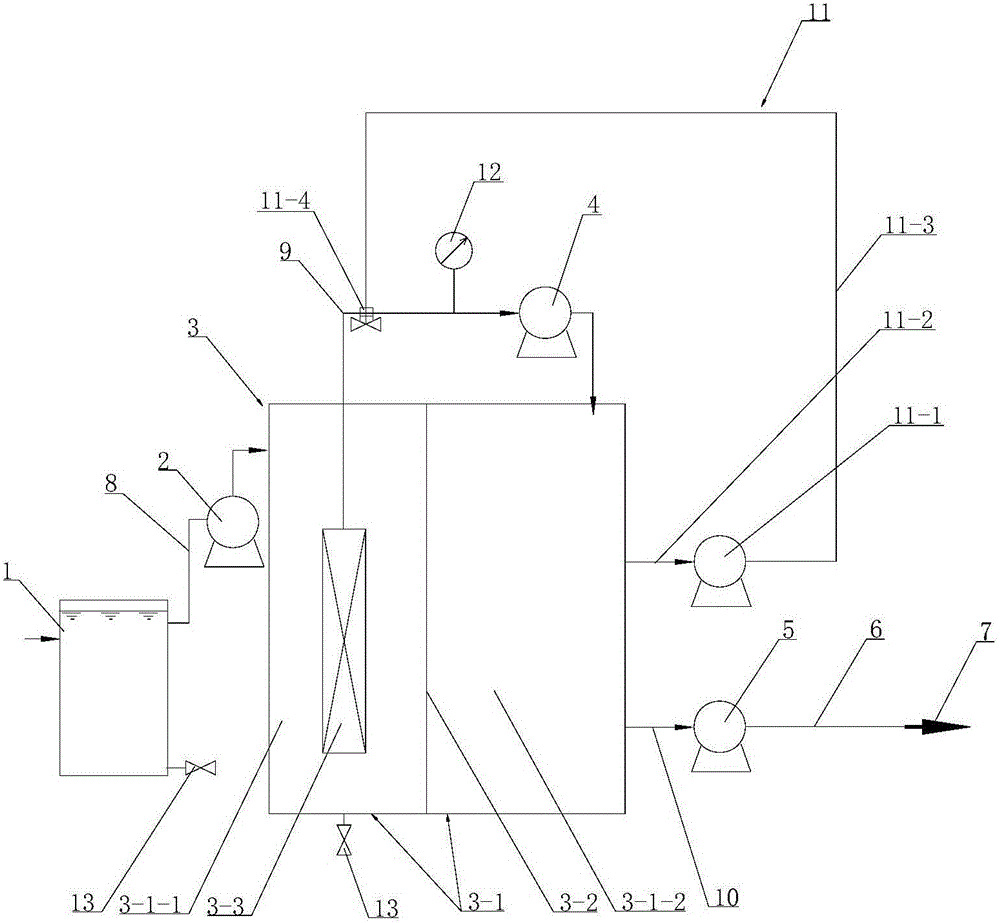

[0015] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0016] See figure 1 , an environment-friendly high-pressure water jet rust removal system, including a sedimentation tank 1, the sedimentation tank is used to store river water or reclaimed water and return sewage after derusting, and a sewage lift pump 2, a membrane treatment device 3, and a negative Pressure pump 4, high-pressure water pump 5, high-pressure water delivery hose 6 and spray gun 7.

[0017] The membrane treatment device includes a general treatment tank 3-1, in which a partition 3-2 is arranged, and the partition divides the interior of the general treatment tank into a membrane tank 3-1-1 and a clean water storage tank 3 -1-2. A membrane module 3-3 for filtration is installed in the membrane tank. Specifically, the membrane ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com