A method for continuous synthesis of polycarboxylate water reducer

A technology of polycarboxylic acid and water reducer, which is applied in the field of concrete admixtures, can solve the problems of wide molecular weight distribution of polymerization products and the inability to effectively control the molecular structure of feed materials, etc., and achieve the effect of narrow molecular weight distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

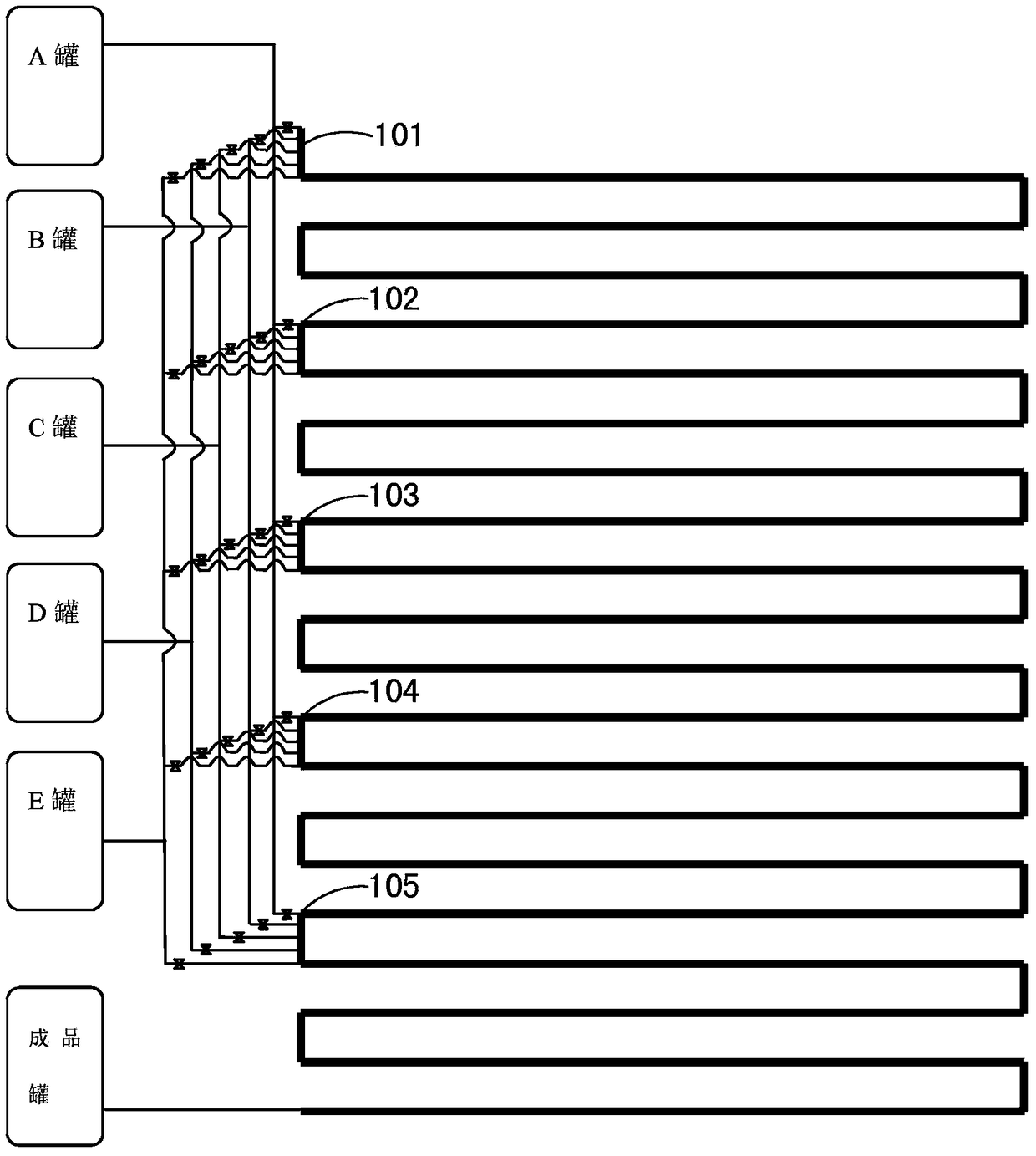

Method used

Image

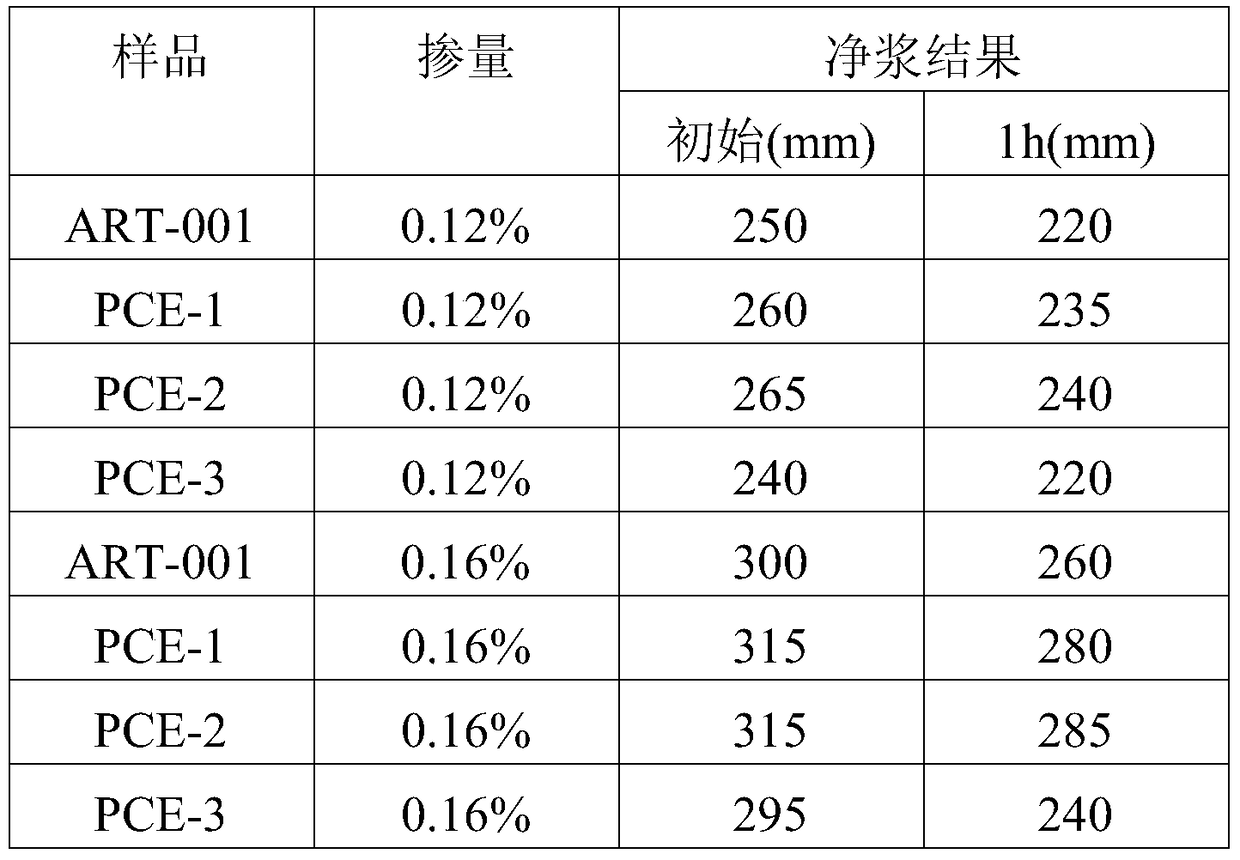

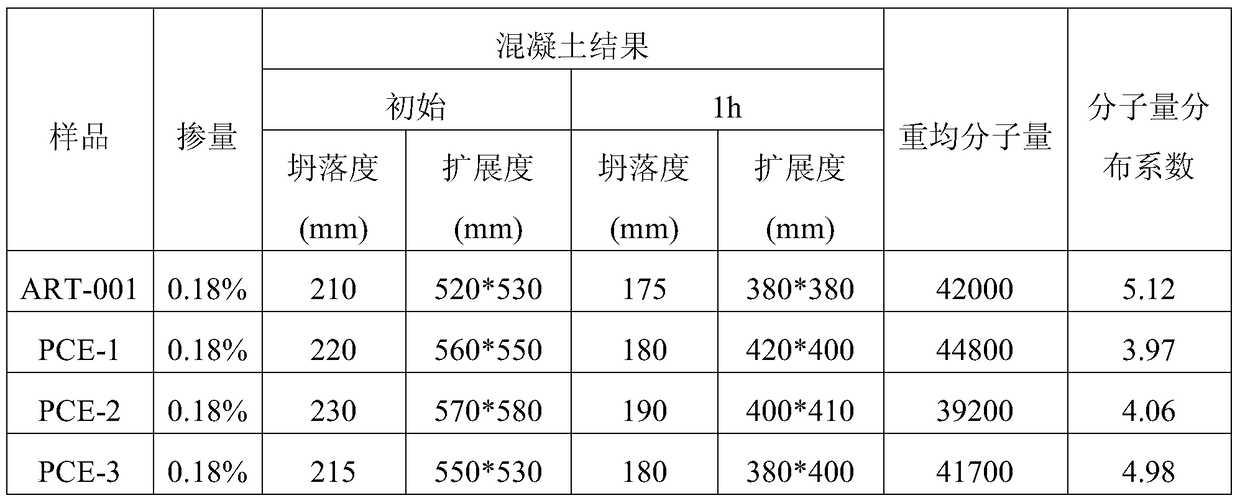

Examples

Embodiment 1

[0069] Add 3000kg of HPEG (methallyl alcohol polyoxyethylene ether) and 3000kg of deionized water to the pretreatment tank A according to the actual formulation requirements of various raw materials used in the synthesis of polycarboxylate water reducer, fully dissolve and stir to obtain solution a Add acrylic acid 360.3kg in pretreatment tank B, deionized water 3000kg, stir to obtain solution b; Add ammonium persulfate 14.7kg in pretreatment tank C, deionized water 60kg, stir to obtain solution c; Pretreatment tank D Add 16.6kg of thioglycolic acid, 80kg of deionized water, and stir to obtain solution d.

[0070] The first feeding point is located at the starting end of the tubular reactor, and the speed of each feeding pump is controlled. At the first feeding point, 6000 kg of a solution and 1680.15 kg of b solution are evenly pumped into the tubular reactor in a 50°C constant temperature water bath. kg, solution c 29.88kg, solution d 48.3kg;

[0071] When the mixed materia...

Embodiment 2

[0078]According to the actual formulation requirements, add 2400kg of HPEG and 3600kg of deionized water into the pretreatment tank A, and fully dissolve and stir the various raw materials used in the synthesis of polycarboxylate water reducer to obtain solution a; 2500kg of deionized water was stirred evenly to obtain solution b; 13.2kg of ammonium persulfate and 60kg of deionized water were added to pretreatment tank C, and solution c was obtained by stirring; 20.1kg of mercaptopropionic acid and 120kg of deionized water were added to pretreatment tank D , Stir evenly to obtain solution d. Add 19.2kg of sodium ascorbate and 80kg of deionized water into pretreatment tank E, and stir to obtain solution e.

[0079] The first feeding point is located at the starting end of the tubular reactor, and the speed of each feeding pump is controlled. At the first feeding point, 3600 kg of a solution and 1129.71 kg of b solution are evenly pumped into the tubular reactor in a 40°C consta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com