Preparation method of beta-zeolite

A beta zeolite and a technology for preparation steps, applied in the field of preparation of zeolite molecular sieves, can solve the problems of reducing synthesis cost, complex treatment method, short crystallization time and the like, and achieve the effect of reducing synthesis cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

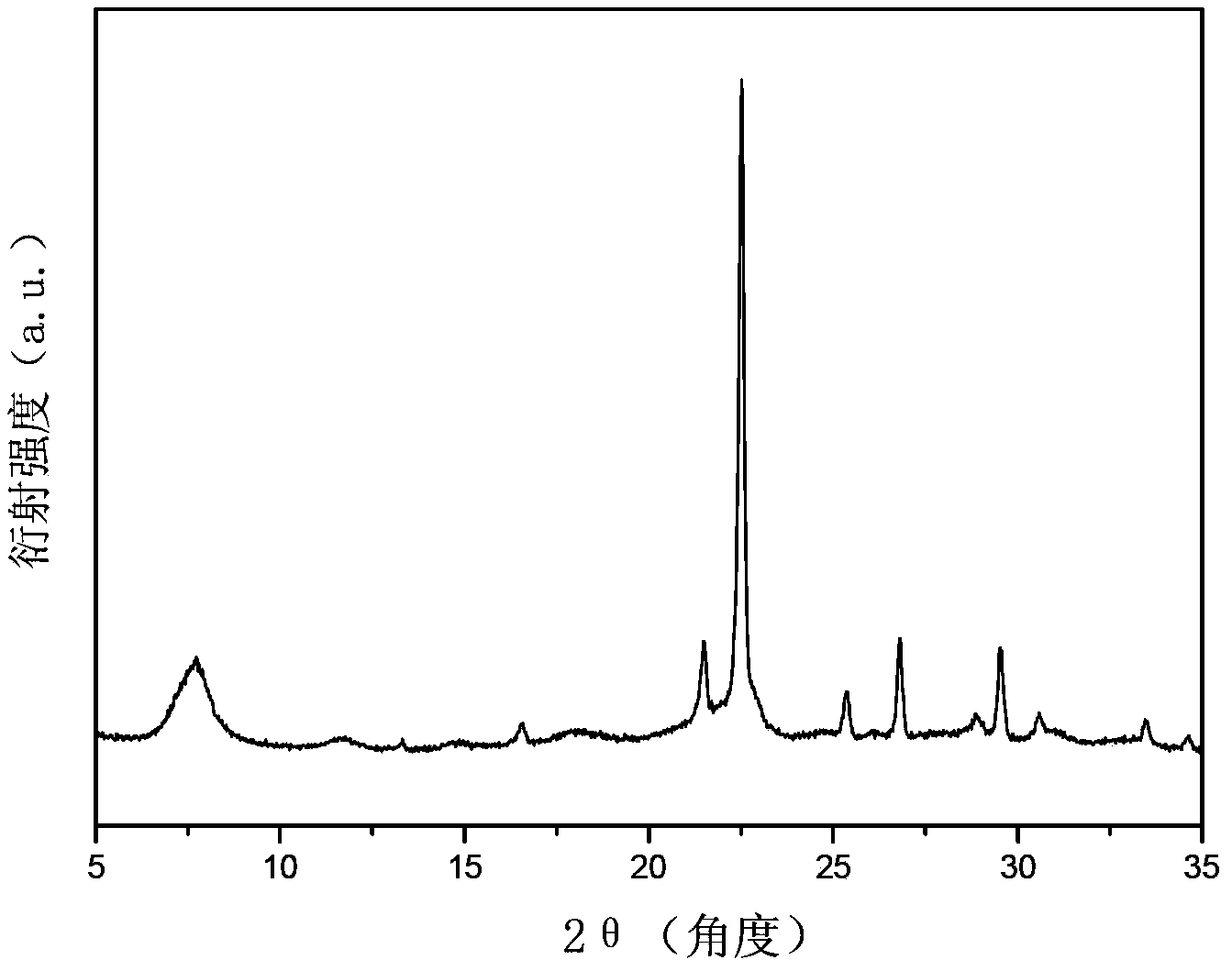

Image

Examples

Embodiment 1

[0023] Take 6.75g deionized water, add 1.10g tetraethylammonium bromide (effective content 95%), 0.42g sodium hydroxide (effective content 96%), 0.36g sodium aluminate (Al 2 o 3 Content 45%), stir until the mixed solution is clear, add 3.00g coarse-porous silica gel (SiO 2 content 96%), stirred for 2 hours, aged at 80°C for 12 hours, placed the resulting initial reaction mixture on a multi-layer sieve plate in the reactor, and added 1.00 g of deionized water and 0.50 g of triethylamine at the bottom of the reactor, Crystallize at 140° C. for 24 hours, filter, wash and dry the resulting sample to obtain a zeolite beta sample.

Embodiment 2

[0025] Take 6.75g deionized water, add 1.50g tetraethylammonium bromide (effective content 95%), 0.48g sodium hydroxide (effective content 96%), 0.18g sodium aluminate (Al 2 o 3 Content 45%), stir until the mixed solution is clear, add 3.00g coarse-porous silica gel (SiO 2 content 96%), stirred for 2 hours, aged at 80°C for 12 hours, placed the resulting initial reaction mixture on a multi-layer sieve plate in the reactor, and added 0.85g deionized water and 0.55g triethylamine to the bottom of the reactor, Crystallize at 140° C. for 24 hours, filter, wash and dry the resulting sample to obtain a zeolite beta sample.

Embodiment 3

[0027] Take 9.25g deionized water, add 1.60g tetraethylammonium bromide (effective content 95%), 0.45g sodium hydroxide (effective content 96%), 0.16g sodium aluminate (Al 2 o 3 Content 45%), stir until the mixed solution is clear, add 3.00g of white carbon black (SiO 2 content 98%), stirred for 2 hours, aged at 80°C for 12 hours, placed the resulting initial reaction mixture on a multi-layer sieve plate in the reactor, and added 0.80 g of deionized water and 0.50 g of triethylamine to the bottom of the reactor, Crystallize at 140° C. for 24 hours, filter, wash and dry the resulting sample to obtain a zeolite beta sample.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com