Hydrothermal synthesis method of monoclinic phase vanadium dioxide nano-powder

A vanadium dioxide nano, hydrothermal synthesis technology, applied in the field of photocatalytic materials, can solve the problems of complex preparation process, difficult control, unfavorable synthesis product repeatability and mass production, and achieve high chemical activity and large specific surface area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] At room temperature, 2.2 g of ammonium dioxalate dioxovanadate complex was dissolved in 50 mL of deionized water and transferred to a reaction kettle for hydrothermal crystallization. The heating rate in the reactor was 5°C min -1 (that is, increase by 5°C per minute), keep at a constant temperature of 180°C for 20 hours, then naturally cool to room temperature and take it out; after washing with alcohol, dry it in an environment of 60±1°C to obtain monoclinic vanadium dioxide nanopowder body.

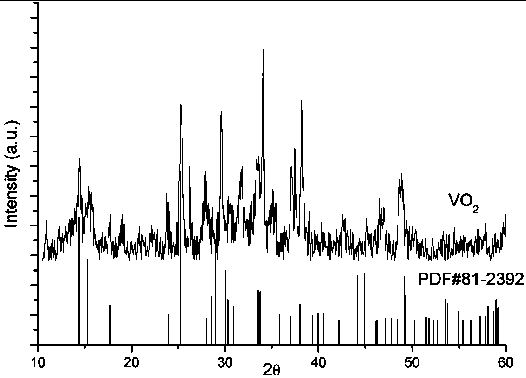

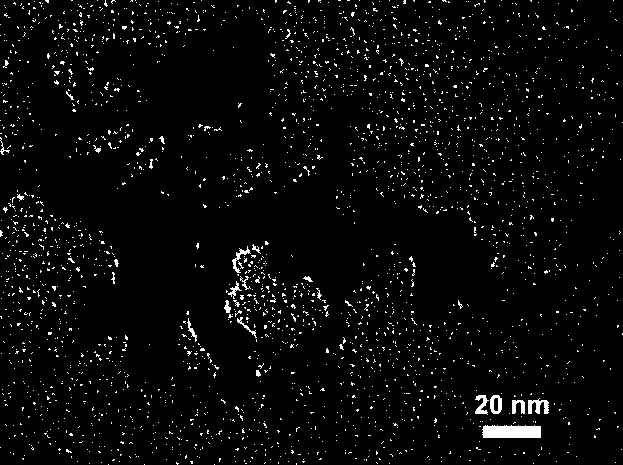

[0032] figure 1 It is the VO of embodiment one hydrothermal synthesis 2 The XRD pattern of nanoparticles (that is, monoclinic vanadium dioxide nanopowder) shows that it has a monoclinic C2 / m(12) structure. figure 2 It is the VO of embodiment one hydrothermal synthesis 2 TEM photo of nanoparticles, VO can be seen from the small black dots in the picture 2 The shape of the nanoparticle is about 1-2 nanometers in diameter.

Embodiment 2

[0034] At room temperature, 2.2 g of ammonium dioxalate dioxovanadate complex was dissolved in 30 mL of deionized water, transferred to a reaction kettle for hydrothermal crystallization. Heating rate is 5°C min -1 , kept at 180°C for 20 h, then cooled naturally to room temperature and taken out. After alcohol washing, dry at 60±1°C to obtain monoclinic phase vanadium dioxide nanopowder.

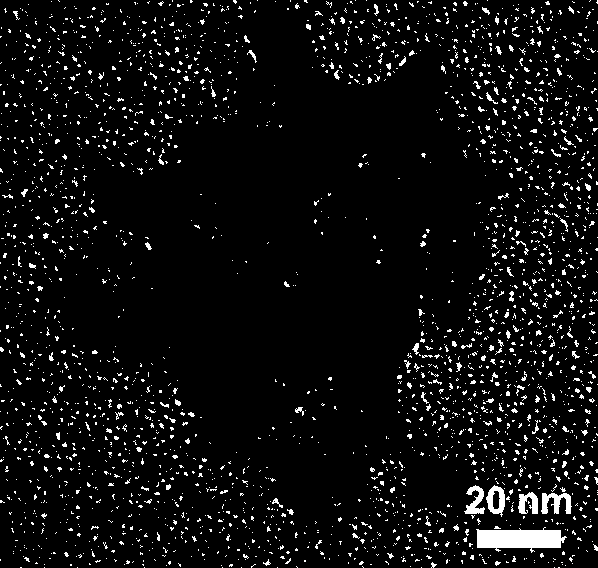

[0035] image 3 It is the VO of embodiment two hydrothermal synthesis 2 TEM photo of nanoparticles, VO can be seen from the small black dots in the picture 2 The shape of the nanoparticle is still about 1-2 nanometers in diameter. It shows that changing the concentration of the raw material solution within a certain range has little effect on the shape and size of the synthesized nanoparticles, which is beneficial to the repeated preparation and mass production of the product.

Embodiment 3

[0037] Take 2.2 g of ammonium dioxalate dioxovanadate complex and dissolve it in 50 mL of deionized water, transfer it to a reaction kettle for hydrothermal crystallization. Heating rate is 5°C min -1 , kept at 200°C for 20 h, then cooled naturally to room temperature and taken out. After alcohol washing, dry at 60±1°C to obtain monoclinic phase vanadium dioxide nanopowder.

[0038] Figure 4 It is the VO of embodiment three hydrothermal synthesis 2 TEM photo of nanoparticles, VO can be seen from the small black dots in the picture 2 The shape of the nanoparticle is still about 1-2 nanometers in diameter. It shows that changing the hydrothermal temperature within a certain range has little effect on the morphology and size of the synthesized nanoparticles, which is beneficial to the repeated preparation and mass production of products.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com