Garbage progressive grading pyrolysis device capable of preventing generation of dioxin

A technology for grading pyrolysis and waste, applied in lighting and heating equipment, combustion methods, combustion types, etc., can solve the problems of insufficient heat utilization efficiency, high waste incineration cost, and large one-time investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Take the processing of domestic waste and medical waste in the present invention as an example below.

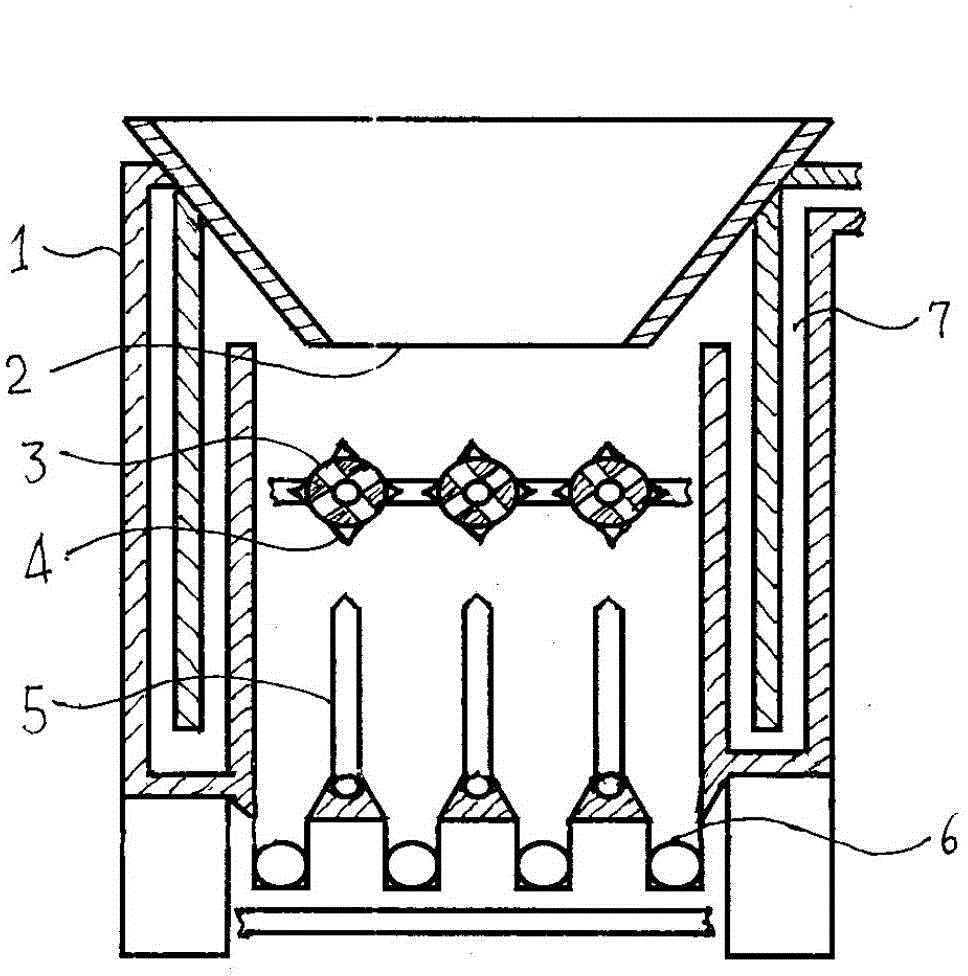

[0026] As shown in the accompanying drawing, the garbage progressive graded pyrolysis device for preventing dioxin generation in the present invention includes a pyrolysis chamber 1 with a garbage inlet 2, an ember output mechanism 6, and a flue gas channel 7, below the garbage inlet 2 Three primary heat transfer pipes 3 are placed horizontally at intervals, and three secondary heat transfer pipes 5 are vertically arranged at intervals below the primary heat transfer pipes 3. The primary heat transfer pipes 3 form a rotatable connection with the power mechanism. The stage heat transfer pipe 5 is provided with an air transfer port for transferring hot air, and the flue gas channel 7 is curved up and down along the wall of the pyrolysis chamber 1 .

[0027] The primary heat transfer pipe 3 is provided with convex spines 4 which are dislocated at intervals. The convex sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com