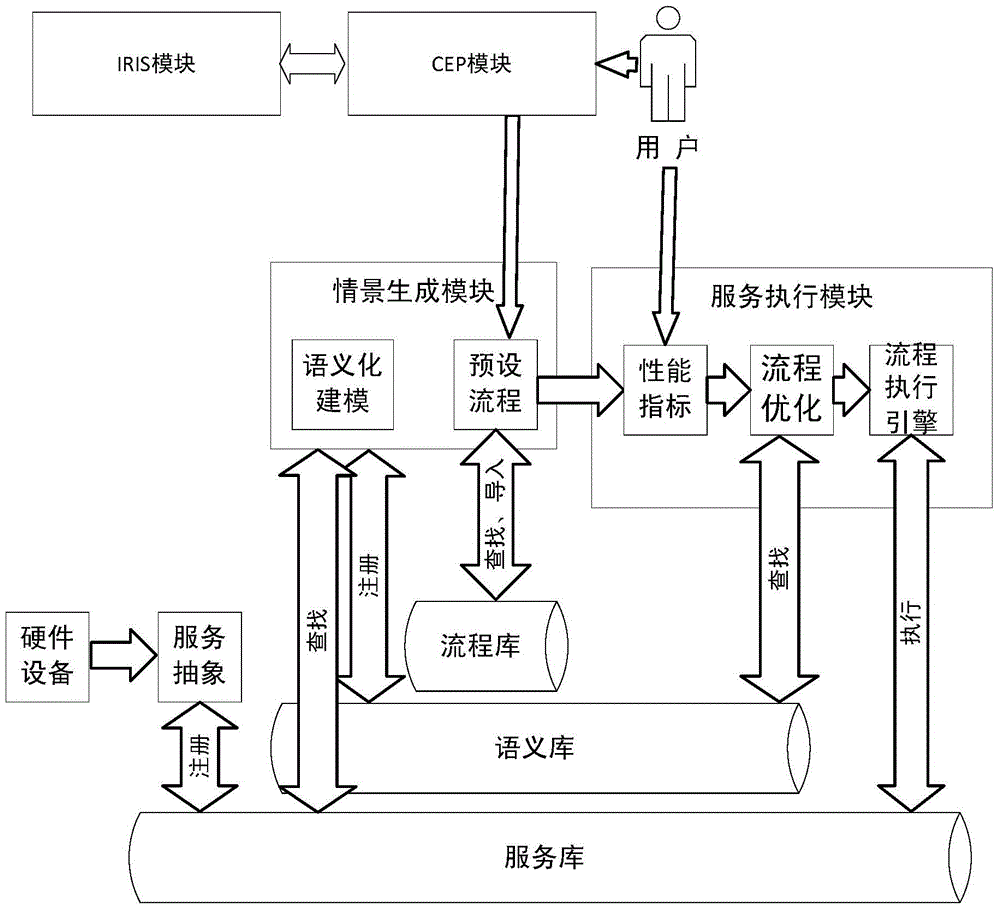

Production line scheduling method and system based on CEP inference engine

A technology of reasoning engine and scheduling method, applied in the field of intelligent manufacturing control, can solve problems such as inflexibility and streamlined production line, and achieve the effects of increasing flexibility, improving production efficiency, and reducing instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to make the objectives, technical solutions and advantages of the present invention clearer and clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

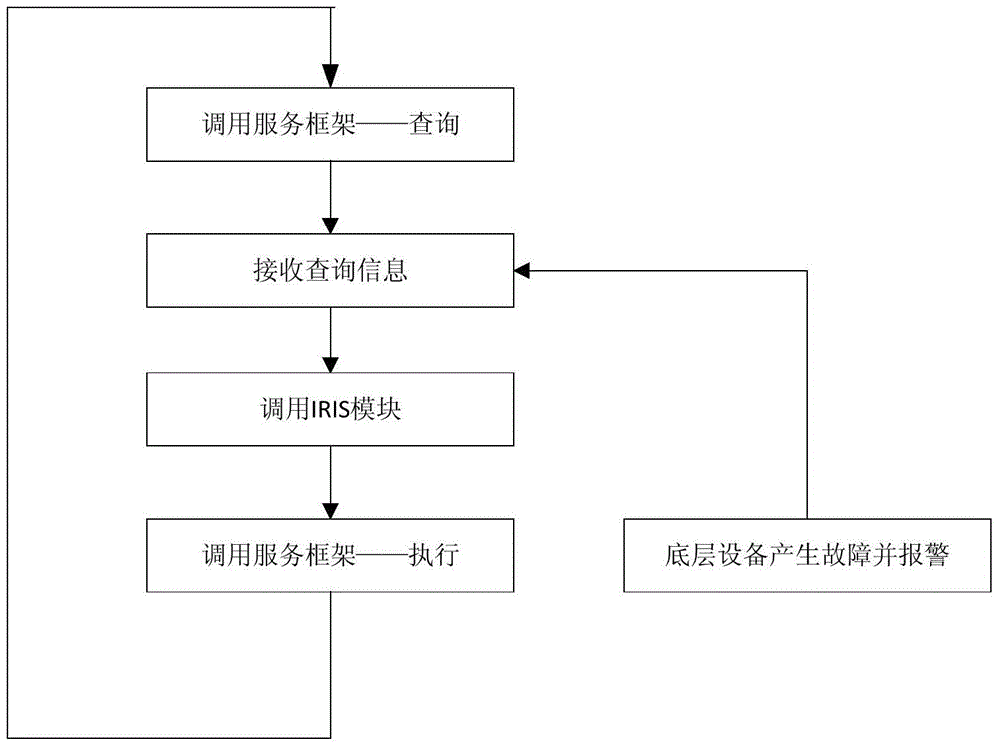

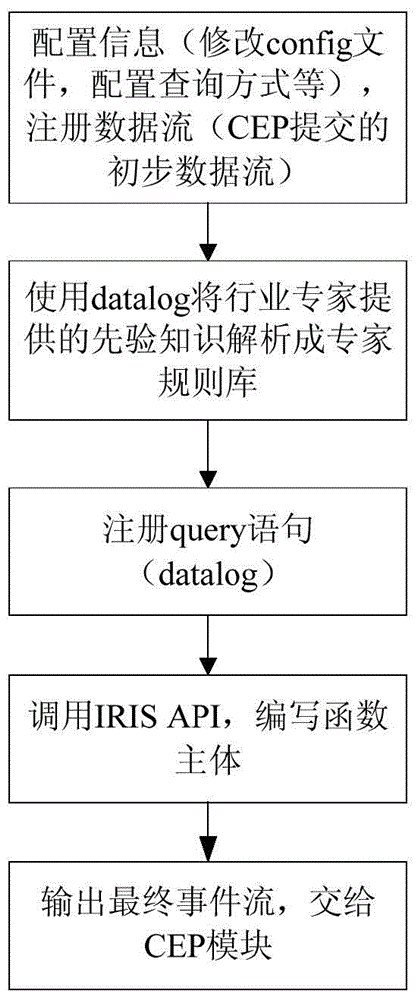

[0042] The present invention includes the following steps:

[0043] 1) Disassemble user orders into atomic operations of the underlying equipment; query the service library to obtain the status and executable operations of the same type of underlying equipment that can complete an atomic operation, and determine the underlying equipment that can complete the atomic operation according to the query results List and the executable operation list of each bottom device; according to the executable operation list, assign corresponding atomic operations to each type of idle bottom device;

[0044] 2) Combine atomic operations of the same purpose into an intermediate data stream according to different purposes of atomic operations, merge and iterate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com