Composite encapsulating structure for high-frequency electrical product

An electrical product, high-frequency technology, applied in the field of composite potting structure of high-frequency electrical products, can solve the problems of high thermal conductivity, high adhesive force, easy to fall off, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

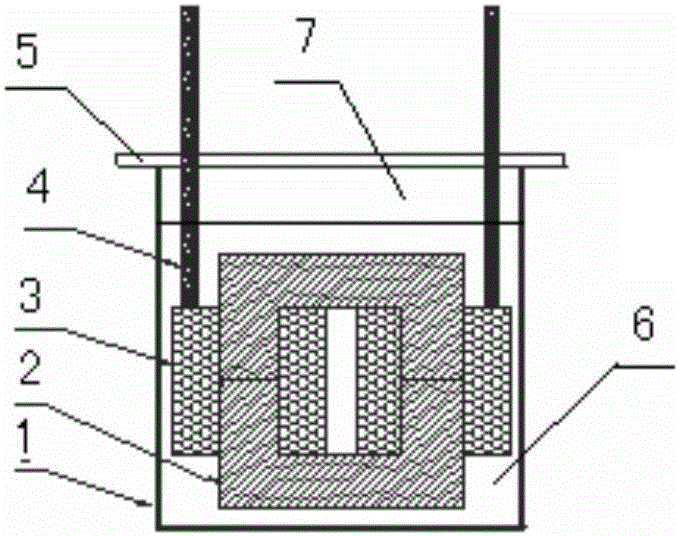

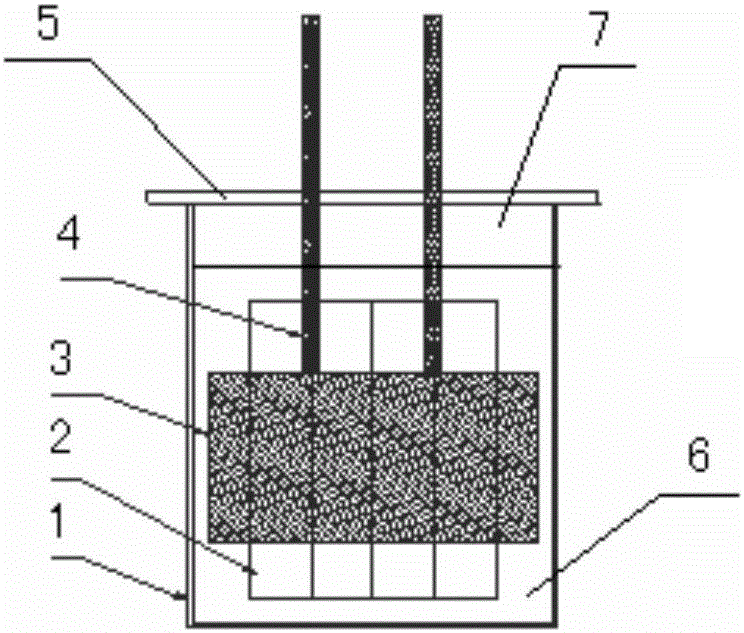

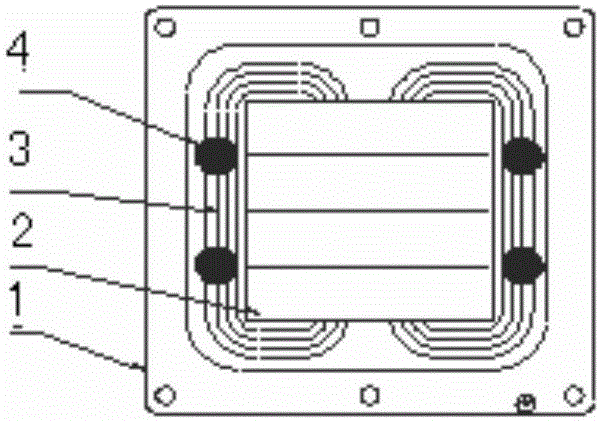

[0019] see Figure 1 to Figure 3 , the compound encapsulation structure of the high-frequency transformer shown in the figure, including the casing 1 and the cover 5 covering the top opening of the casing 1, and the iron core 2, winding 3, and winding 3 of the high-frequency transformer arranged in the casing 1 Lead out through a pair of lead wires 4 which pass through the cover 1 . A soft rubber insulator 6 is potted between the iron core 2 , winding 3 and the inner wall of the housing 1 of the high frequency transformer, and a hard rubber insulator 7 is potted between the upper surface of the soft rubber insulator 6 and the bottom surface of the cover 5 . The maximum distance between the upper surface of the soft rubber insulator 6 and the bottom surface of the cover 5 is 25-30 mm.

[0020] The operation process is to put the iron core 2 and winding 3 of the high-frequency transformer that have passed the intermediate test into the shell 1, then carry out soft glue potting,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com