Production process for control annunciator of high-strength and abrasion-resistant automobile antiblock brake system (ABS)

An ABS system and control signal technology, which is applied in the production technology field of high-strength wear-resistant automotive ABS system control signal device, can solve the problems of magnetic performance inductive signal influence, large material life and loss, easy entry of sand and gravel into wheels, etc. Achieve the effects of stable signal transmission, long service life and strong magnetism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

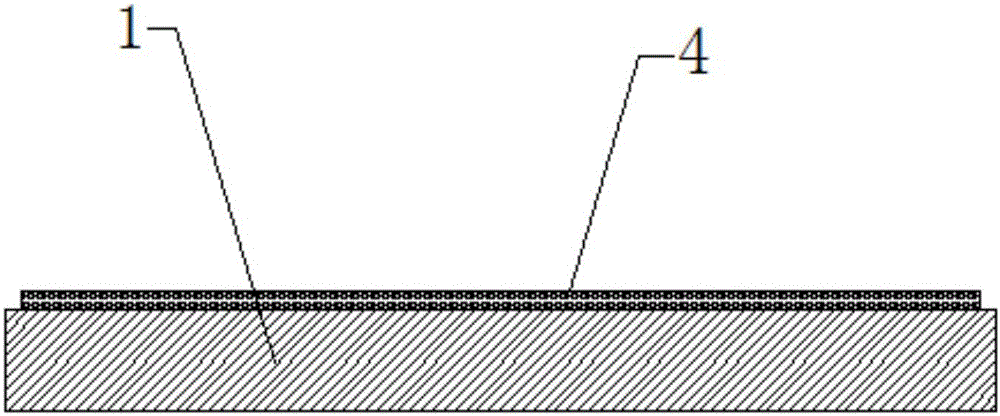

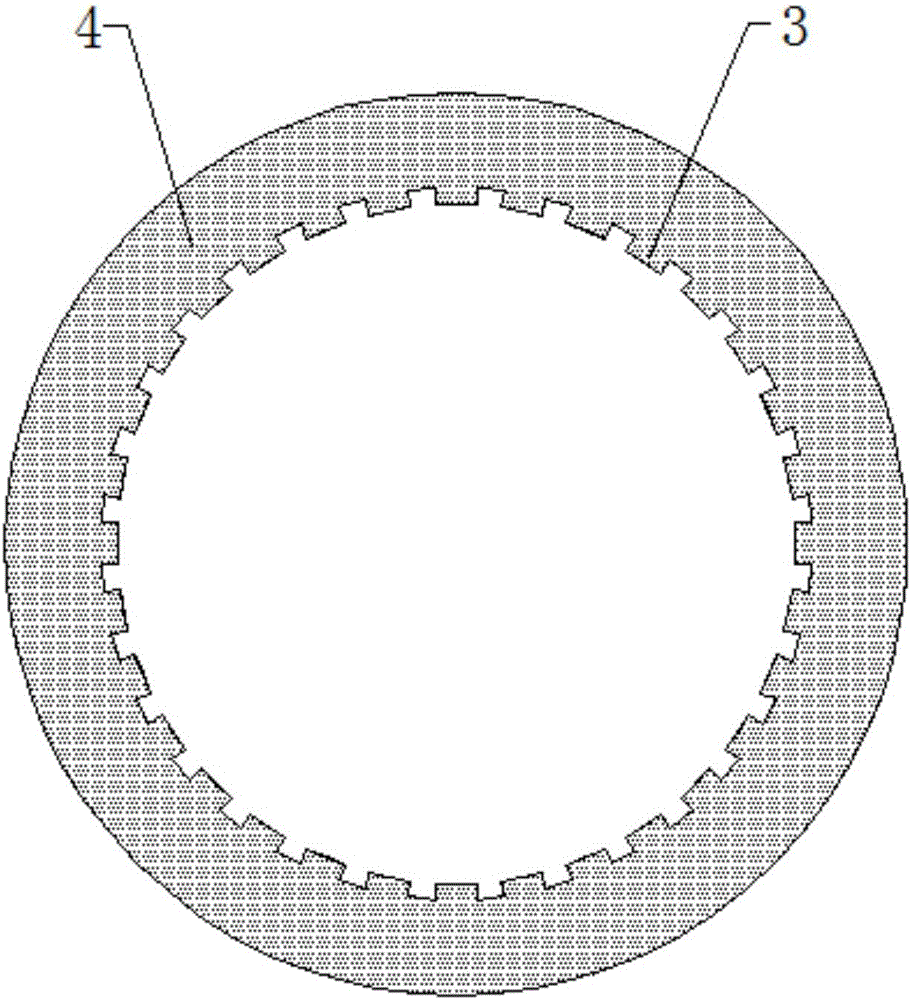

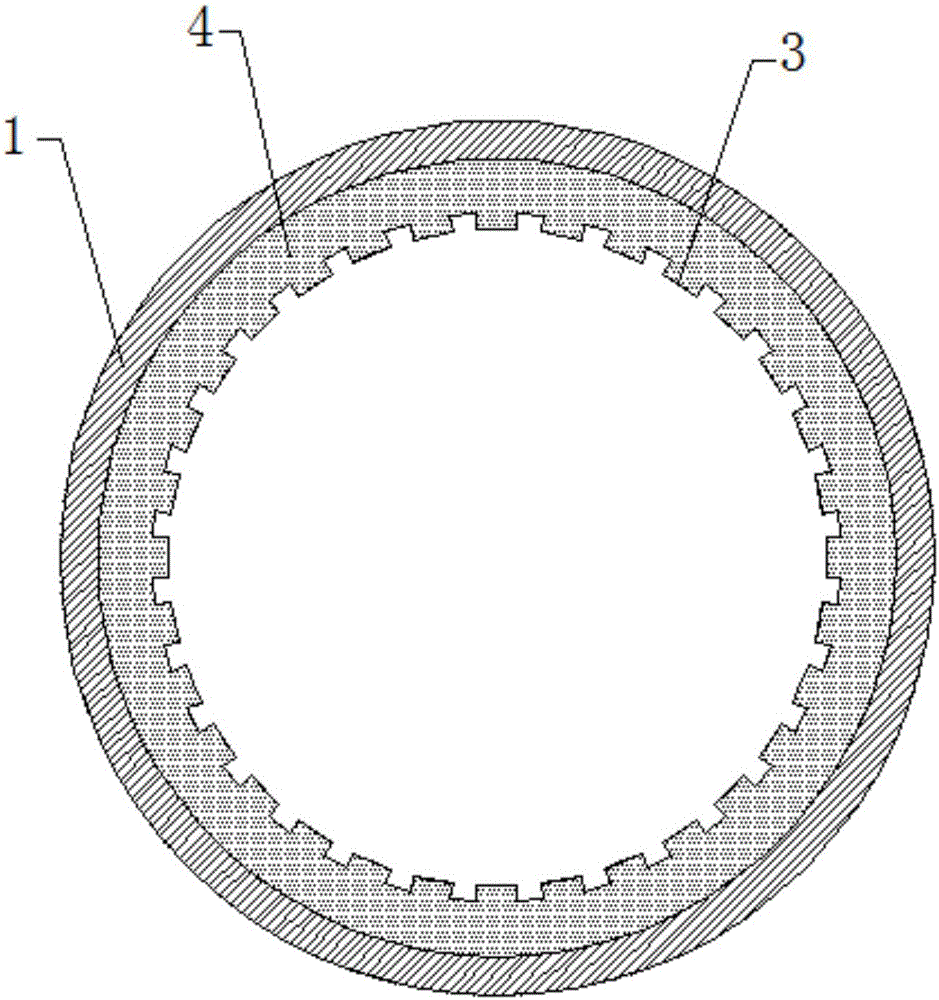

[0033] Embodiment one: with reference to attached Figure 1-3 The production process of the high-strength and wear-resistant automotive ABS system control signal device includes the following steps:

[0034] 1) Components and content of the raw material of the magnetic ring: according to the percentage by weight, it includes 87.5wt% of strontium ferrite, 10wt% of nylon 6610wt%, 1.2wt% of cumyl peroxide and 1wt% of silane coupling agent;

[0035] 2) Sieving and weighing: Weigh the above-mentioned raw material components according to the proportion and pass them through 80, 100, and 120 mesh screens for three-stage screening. The particle size of the raw materials after three-stage screening is more uniform, easier to mix, and can It plays an auxiliary role in the subsequent primary extrusion and secondary extrusion, and improves the mixing uniformity of the particles;

[0036] 3) primary mixing and stirring: the raw materials sieved in step (2) enter into the mixer for mixing ...

Embodiment 2

[0050] Embodiment 2: Different from Embodiment 1,

[0051] 1) Components and content of the raw material of the magnetic ring: according to the percentage by weight, it includes 88wt% of strontium ferrite, 669wt% of nylon, 1.4wt% of cumyl peroxide and 0.9wt% of silane coupling agent;

[0052] 3) Primary mixing and stirring: the raw materials sieved in step (2) enter into the mixer for mixing in turn, and the stirring speed is 120r / min;

[0053] 4) Drying: The mixed material enters the dryer for drying, the drying temperature is 110°C, the temperature during the drying process starts from 0°C, and gradually increases the temperature to 110°C at a rate of 5°C per minute , and keep warm and dry for 1.2 hours;

[0054] 5) One-time extrusion: the mixed material enters the extruder for extrusion molding, and the material is extruded in a molten state, the extrusion temperature is 260°C, and a primary preheating device is installed at the feed port of the extruder;

[0055] 7) Seco...

Embodiment 3

[0058] Embodiment 3: Different from Embodiment 1,

[0059] 1) Components and content of magnetic ring raw materials: according to weight percentage, it includes 90wt% of strontium ferrite, 668wt% of nylon, 1.5wt% of cumyl peroxide and 0.8wt% of silane coupling agent;

[0060] 3) primary mixing and stirring: the raw materials sieved in step (2) enter into the mixer for mixing in turn, and the stirring speed is 150r / min;

[0061] 4) Drying: The mixed material enters the dryer for drying, the drying temperature is 100°C, the temperature during the drying process starts from 0°C, and gradually increases the temperature to 100°C at a rate of 5°C per minute , and keep warm and dry for 1.5 hours;

[0062] 5) One-time extrusion: the mixed material enters the extruder for extrusion molding, and the material is extruded in a molten state, the extrusion temperature is 270°C, and a primary preheating device is installed at the feed port of the extruder;

[0063] 7) Secondary mixing and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com