3-dimensional bioscaffolds

A biological scaffold, 3D technology, applied in the field of implants for the treatment of injuries such as but not limited to meniscus injuries, can solve problems such as limited applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

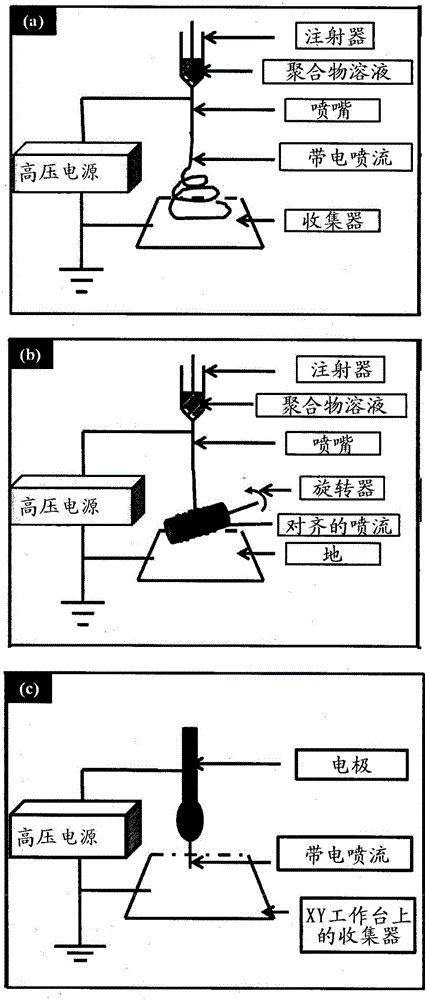

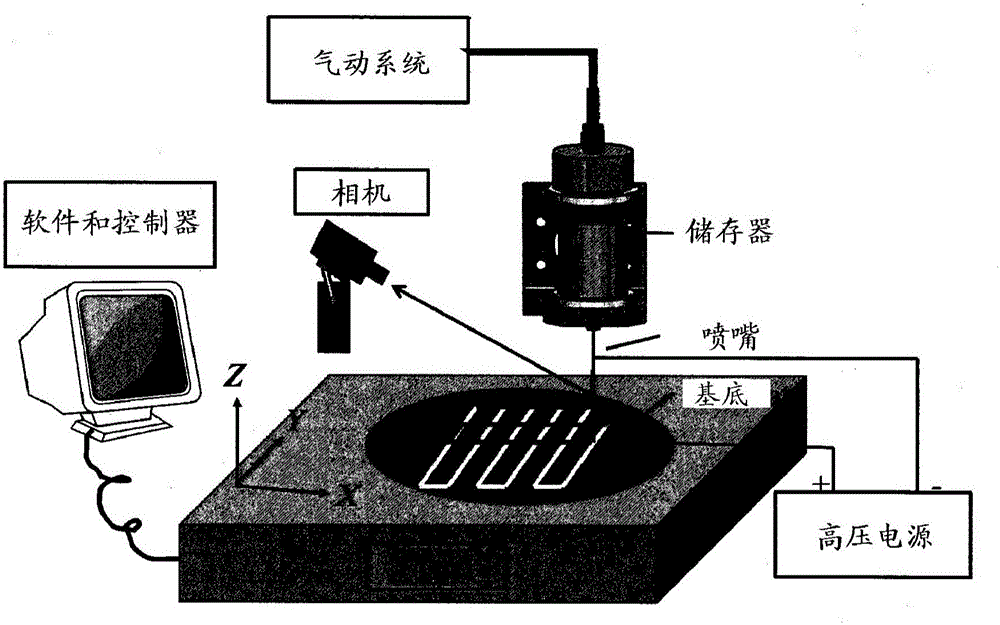

Method used

Image

Examples

Embodiment 1

[0094]Embodiment 1: the influence of PCL solution concentration

[0095] Concentration refers herein to the weight-to-volume ratio of PCL in acetic acid, which is critical for the formation of filaments, and thus for the fabrication of bioscaffolds. In the traditional electrospinning process, the most commonly used PCL solution concentration is 8% to 12% (Seeram et al. 2005), while in the E-jet process, no filaments are produced at such low concentrations ( Figure 4 a). A broad line of solution appeared only on the substrate, which was attributed to insufficient time for the solvent to evaporate. Complete drying of the printed wires took more than 5 min, making it impossible to construct bioscaffold structures. Increasing the concentration of PCL solution up to 70% was investigated to study the effect of concentration on silk production and bioscaffold fabrication, and the results are shown here.

[0096] PCL filaments can be obtained using a 30% solution. Repeated printing...

Embodiment 2

[0100] Example 2: Characterization of Biological Scaffolds

[0101] Figure 5 SEM examination of E-jetted PCL filaments is shown in a. Parallel filaments were obtained, and the surface of the printed filaments was generally smooth. Under the action of high voltage, uniform filaments with a diameter of 20.5±1.9 μm were realized. This is much smaller than filaments produced using a microextrusion system with a filament diameter of 100 μm (Kalita et al. 2003, Wei et al. 2012). Filaments have been shown to enhance cell attachment and modulate cell signaling pathways, thereby accelerating extracellular matrix production (Nur-E-Kamal et al. 2005, Li et al. 2006).

[0102] According to literature reports, the pore size of electrospun bioscaffolds is small compared to the size of cells, thereby limiting the passage of cells into bioscaffolds (Kidoaki et al. 2005). To evaluate this, a 10-layer bioscaffold ( Figure 5 b). The obtained pore size was 450±50 μm. A large pore size wo...

Embodiment 3

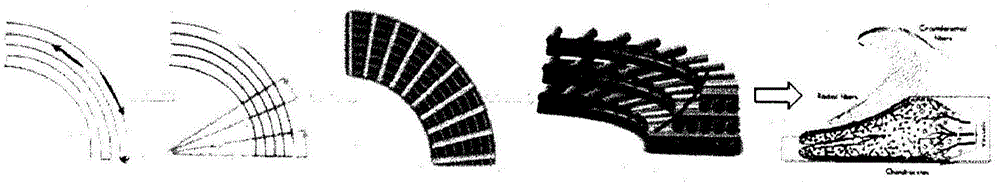

[0105] Example 3: In Vitro Study of Chondrocyte Response on Biological Scaffolds

[0106] After 3 days of culture, the viability of chondrocytes on the fibrous bioscaffolds was assessed using a live / dead staining method. It was found that a large number of live chondrocytes (highlighted part in the figure) attached to and spread on the surface of collagen-coated PCL filaments, showing good cell viability ( Figure 7 a). In addition, chondrocytes adhered to the inner surface of the bioscaffold were seen, showing good cell infiltration. Some cells were well in focus in the plane, while others were not, implying that these cells were attached in different layers of the bioscaffold.

[0107] Figure 7 b shows sGAG production on cell-loaded bioscaffolds and controls. The amount of sGAG content on each sample increased with incubation time. However, sGAG produced by chondrocytes on bioscaffolds was significantly higher than that of controls at all time points. The results show...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com