Semi-blanching colocasia esculenta processing and manufacturing method

A production method and technology of taro, applied in food ultrasonic treatment, function of food ingredients, food science, etc., can solve problems such as loss of nutrients, shortened shelf life, easy mildew of taro, etc., to achieve smooth production workshop and improved market reflection , The effect of shortening the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

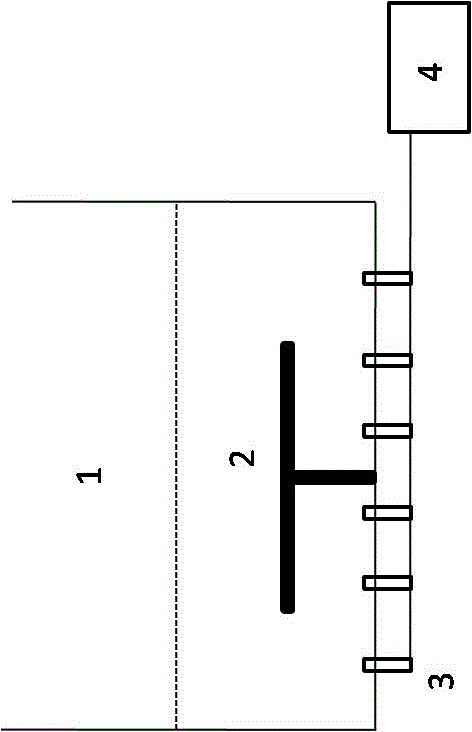

Image

Examples

Embodiment 1

[0030] A method for processing half blanched taro, comprising the following steps:

[0031] (1) The taro is selected, removed impurities, moldy and deteriorated taro, washed, and then peeled under the condition of spraying the color-protecting agent. The peeled taro is quickly soaked in the color-protecting agent, and the ultrasonic power is 1000 for 30 minutes. ;

[0032] Among them, the color-protecting agent is composed of 1.5% citric acid, 0.3% vitamin C, 0.2% EDTA, and 0.5% chitosan mixed solution; the molecular weight of chitosan is 100,000 Da, and the degree of deacetylation is 75%.

[0033] (2) The peeled taro is transported to the weighing device by a feeding machine; after calculation, according to the ratio of taro and air bubbles is 100kg: 500L, it is transported to the first air bubble net belt cleaning machine, and the air bubbles float to clean the surface;

[0034] (3) After cleaning, the taro is transported to the mesh belt blower to dry the water drops and f...

Embodiment 2

[0041] A method for processing half blanched taro, comprising the following steps:

[0042] (1) After the taro is selected, impurities are removed, moldy and deteriorated taro is removed, cleaned, and then peeled under the condition of spraying the color-protecting agent, the peeled taro is quickly soaked in the color-protecting agent, and the high-power ultrasonic treatment is performed for 30 minutes; the ultrasonic power 1500W;

[0043]Among them, the color-protecting agent is composed of 1.5% citric acid, 0.3% vitamin C, 0.2% EDTA, and 0.5% chitosan mixed solution; the molecular weight of chitosan is 120,000 Da, and the degree of deacetylation is 85%.

[0044] (2) The peeled taro is transported to the weighing device by a feeding machine; after calculation, according to the ratio of taro and air bubbles is 100kg: 500L, it is transported to the first air bubble net belt cleaning machine, and the air bubbles float to clean the surface;

[0045] (3) After cleaning, the taro ...

Embodiment 3

[0053] A method for processing half blanched taro, comprising the following steps:

[0054] (1) The taro is selected, removed impurities, moldy and deteriorated taro, washed, and then peeled under the condition of spraying the color-protecting agent. The peeled taro is quickly soaked in the color-protecting agent, and 2000W power ultrasonic treatment for 30 minutes;

[0055] Among them, the color-protecting agent is composed of 1.5% citric acid, 0.3% vitamin C, 0.2% EDTA, and 0.5% chitosan mixed solution; the molecular weight of chitosan is 150,000 Da, and the degree of deacetylation is 70%.

[0056] (2) The peeled taro is transported to the weighing device by a feeding machine; after calculation, according to the ratio of taro and air bubbles is 100kg: 500L, it is transported to the first air bubble net belt cleaning machine, and the air bubbles float to clean the surface;

[0057] (3) After cleaning, the taro is transported to the mesh belt blower to dry the water drops and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com