Method for processing pepino crisps by microwave puffing

A technology of microwave puffing and processing method, applied in food forming, food drying, food science and other directions, can solve the problems of few high-end products, waste of ginseng fruit resources, low technical content, etc., and achieve unique flavor, strong ginseng fruit aroma, good color and luster. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] The processing method of microwave puffed ginseng fruit chips of the present invention specifically carries out according to the following steps:

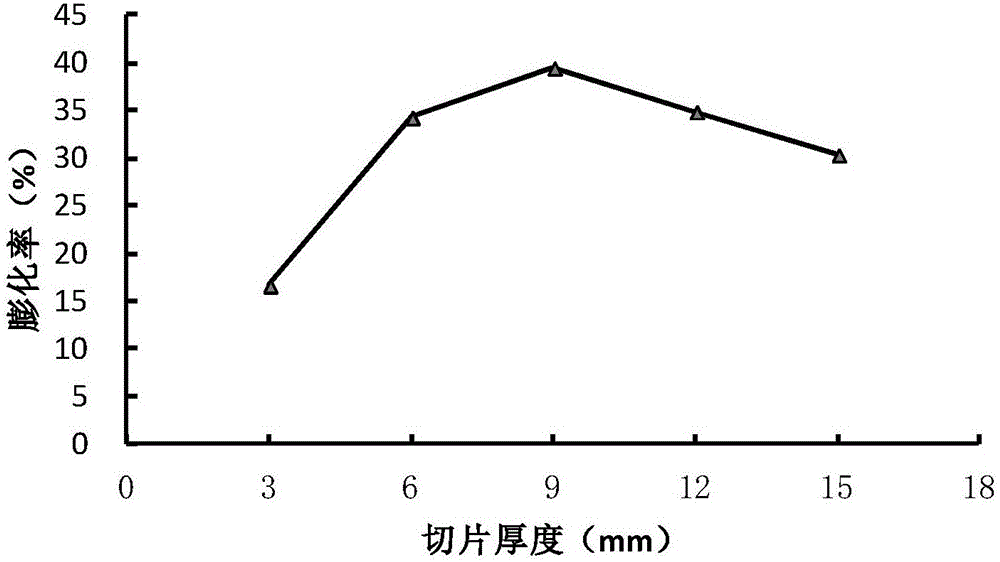

[0070] Step 1, select fresh, eight-mature ginseng fruit without damage by diseases and insect pests, clean it with running water, then peel and slice it, the thickness of the ginseng fruit slice is 6mm, and set aside;

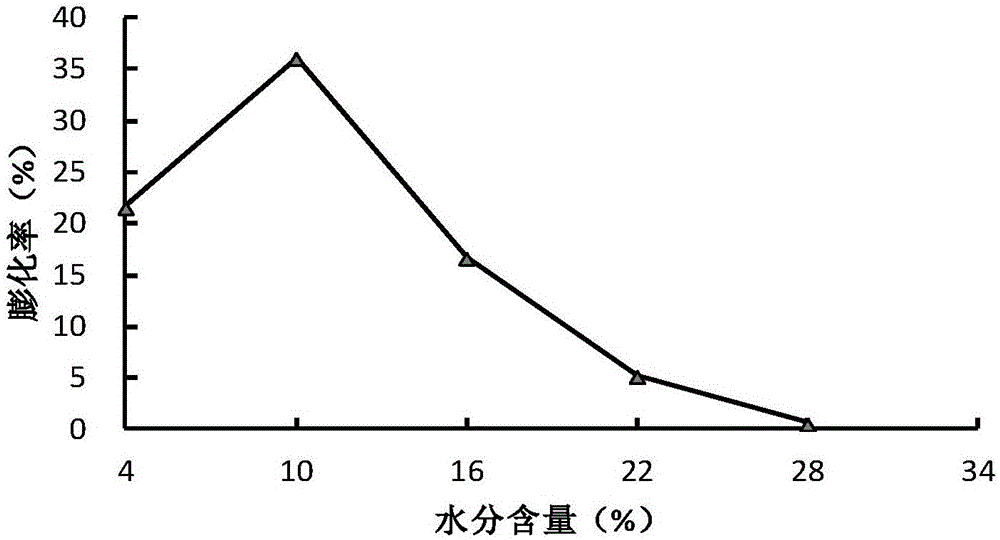

[0071] Step 2, pre-drying: Spread 200g of fresh ginseng fruit slices with a thickness of 6mm on a stainless steel plate, and use a DHG-9240A electric heating constant temperature blast drying oven to perform hot air constant temperature drying at 55°C until the moisture content is 13%;

[0072] Step 3, take out the ginseng fruit slices, seal and balance the water for 2 hours;

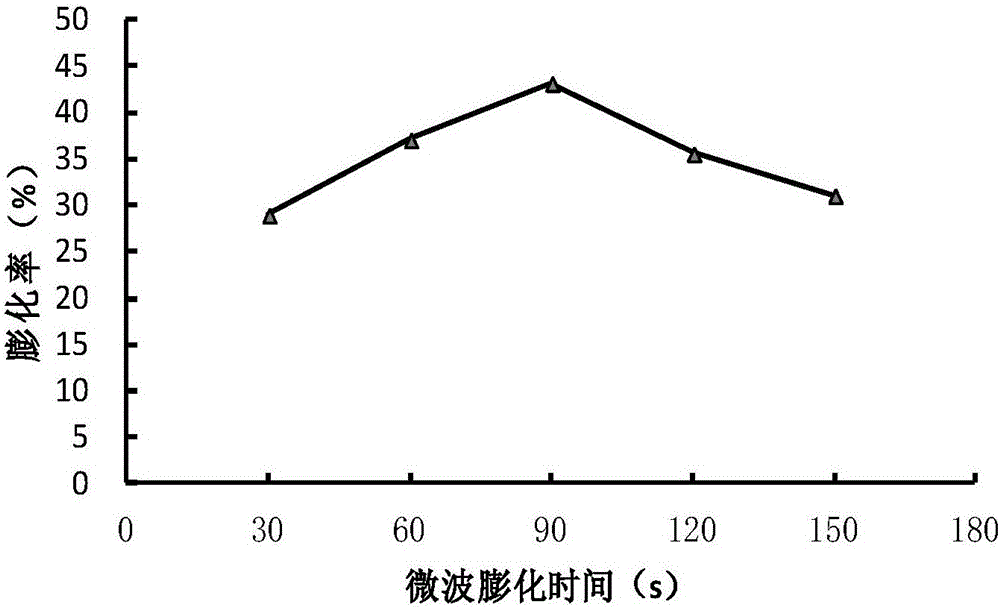

[0073] Step 4, microwave puffing: using a WD700 microwave oven at a microwave power of 420W, microwave puffing for 120s;

[0074] Step 5, secondary drying: at the same temperature as pre-drying, secondary drying at 55° C. until the mo...

Embodiment 2

[0076] The processing method of microwave puffed ginseng fruit chips of the present invention specifically carries out according to the following steps:

[0077] Step 1, select fresh, eight-mature ginseng fruit without damage by diseases and insect pests, clean it with running water, then peel and slice it, the thickness of the ginseng fruit slice is 12mm, and set aside;

[0078] Step 2, pre-drying: Spread 200g of fresh ginseng fruit slices with a thickness of 12mm on a stainless steel plate, and use a DHG-9240A electric heating constant temperature blast drying oven at 95°C to carry out hot air constant temperature drying until the moisture content is 7%;

[0079] Step 3, take out the ginseng fruit slices, seal and balance the water for 4 hours;

[0080] Step 4, microwave puffing: using a WD700 microwave oven at a microwave power of 700W, microwave puffing for 60s;

[0081] Step 5, secondary drying: at the same temperature as pre-drying, secondary drying at 95° C. until the ...

Embodiment 3

[0083] The processing method of microwave puffed ginseng fruit chips of the present invention specifically carries out according to the following steps:

[0084] Step 1, select fresh, eight-mature ginseng fruit free of diseases and insect pests, clean it with running water, then peel and slice it, the thickness of the ginseng fruit slice is 9mm, and set aside;

[0085] Step 2, pre-drying: Spread 200g of fresh ginseng fruit slices with a thickness of 9mm on a stainless steel plate, and use a DHG-9240A electric heating constant temperature blast drying oven at 85°C to carry out hot air constant temperature drying until the moisture content is 10.5%;

[0086] Step 3, take out the ginseng fruit slices, seal and balance the water for 3 hours;

[0087] Step 4, microwave puffing: using a WD700 microwave oven at a microwave power of 600W, microwave puffing for 65s;

[0088] Step 5, secondary drying: at the same temperature as pre-drying, secondary drying at 85° C. until the moisture ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com