Putting green

A green and mixed layer technology, applied in sports accessories, rackets, etc., can solve the problems of unfavorable technology promotion, difficult standardization, and different components, and achieve the effects of simple production method, guaranteed output and stable material properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

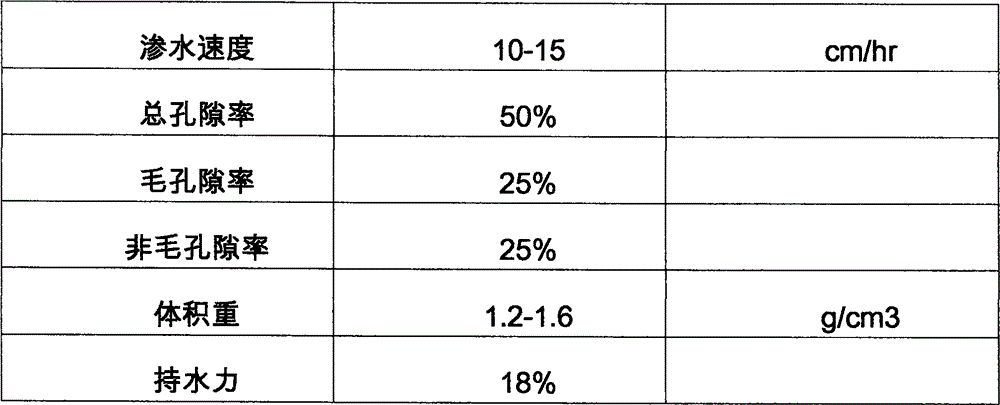

[0017] A kind of putting green that the embodiment of the present invention provides, this putting green comprises foundation, gravel layer, coarse sand filter layer and rhizosphere mixed layer; Described rhizosphere mixed layer comprises the diameter that is less than or equal to 3% of rhizosphere mixed layer total mass Gravel of 2.0-3.4 mm, coarse sand with a diameter of 1.0-2.0 mm less than or equal to 2% of the total mass of the rhizosphere mixed layer, medium-coarse sand with a diameter of 0.25-1.0 mm greater than or equal to 60% of the total mass of the rhizosphere mixed layer Mixture, fine sand with a diameter of 0.15 to 3.4 mm less than or equal to 20% of the total mass of the rhizosphere mixed layer, and sludge particles with a diameter of 0.002 to 0.05 mm greater than or equal to 15% of the total mass of the rhizosphere mixed layer; the sludge particles are It is made by composting, drying in the sun and rolling and crushing. The rhizosphere mixed layer is used for p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com