Continuous production vacuum distillation equipment and process for recovery of iron-containing waste acid liquid

A technology of distillation equipment and waste acid liquid, applied in inorganic chemistry, chlorine/hydrogen chloride, halogen/halogen acid, etc., can solve the problems of increased treatment cost, high treatment cost, inability to reuse, etc., to improve treatment efficiency and treatment effect , the effect of accelerating the evaporation reaction speed and improving the utilization rate of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

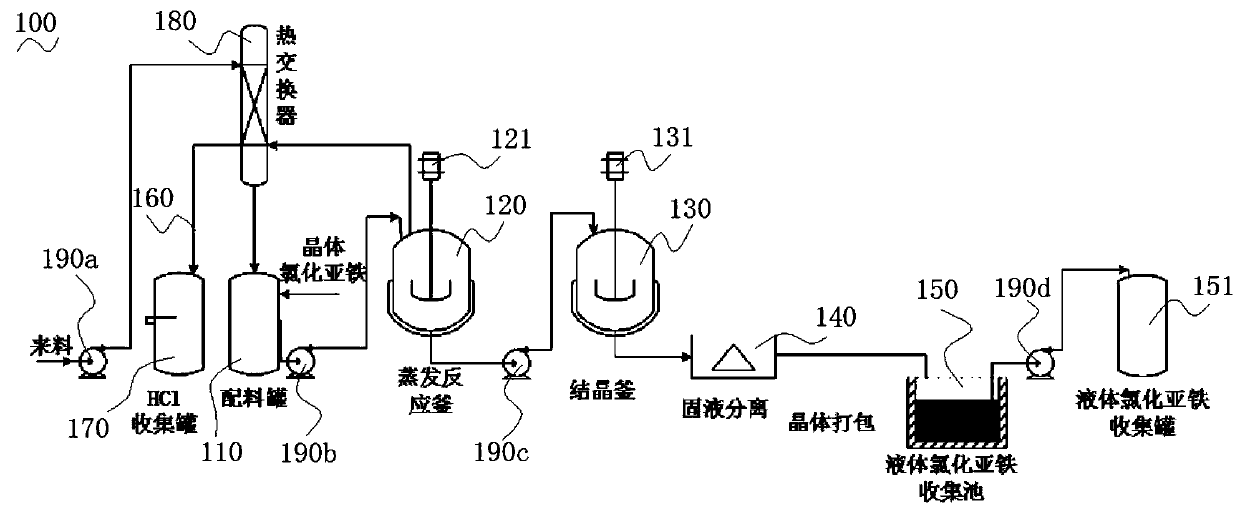

[0030] Such as figure 1 Shown is a structural schematic diagram of a continuous production vacuum distillation equipment for recycling iron-containing waste acid liquid according to the present invention.

[0031] A continuous production vacuum distillation equipment 100 for recovery of iron-containing waste acid liquid, including a batching tank 110 for configuring ferrous chloride solution, connected to the output end of batching tank 110 for evaporating the ferrous chloride solution into a concentrated solution Evaporation reaction still 120, be connected to the crystallization still 130 of ferrous chloride crystal that concentrate liquid is separated out ferrous chloride crystal in evaporating reaction still 120 output ends, be connected to ferrous chloride crystal and ferrous chloride crystallization after crystallization still 130 output ends The solid-liquid separation tank 140 that ferric solution is separated, be connected to the ferrous chloride solution collection p...

specific Embodiment 2

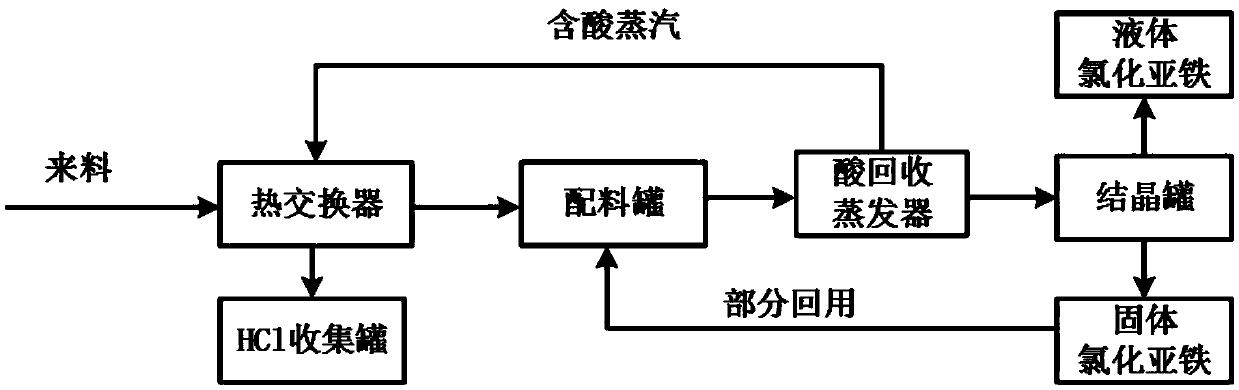

[0038] Such as figure 2 Shown is a process flow diagram of a continuous production vacuum distillation process for the recovery of iron-containing waste acid liquid of the present invention.

[0039] A continuous production vacuum distillation process for recovering iron-containing waste acid liquid, ① transporting the iron-containing waste acid liquid to be treated to the heat exchanger 180 for heating, and then transporting the heated iron-containing waste acid liquid to the batching tank 110; 2. Add ferrous chloride crystals to the batching tank 110 to obtain a ferrous chloride solution, and then transport the ferrous chloride solution to the evaporation reactor 120; The air pipe 160 and the heat exchanger 180 enter the HCl collection tank 170 after heat exchange occurs, and the evaporated concentrated solution is transported to the crystallization tank 130; ④ the crystallization tank 130 is cooled and crystallized; Ferrous solution and ferrous chloride crystal are separa...

specific Embodiment 3

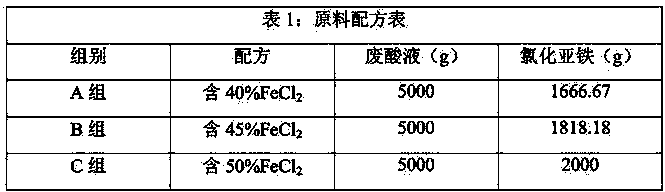

[0044] Specific embodiment 3: the recovery and treatment effect of the distillation process of the present invention and the rationality of process parameter selection are verified by specific experiments.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com