Intensive cooling control device and control method of microalloyed steel continuous casting slab corners in vertical bending segment

A technology of micro-alloy steel and control device, which is applied in the field of control in the field of steelmaking-continuous casting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

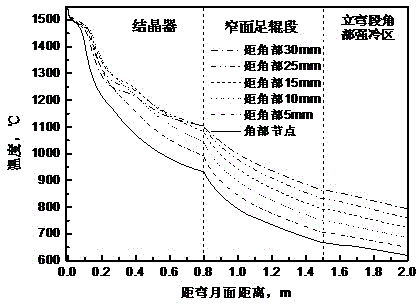

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

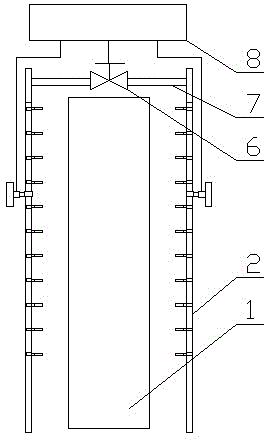

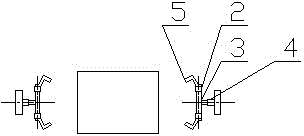

[0026] like Figure 1-2 The shown micro-alloy steel continuous casting slab corner vertical bending section forced cooling control device includes two sets of spray racks 2 installed on both sides of the continuous casting slab vertical bend section 1, and each set of spray racks includes two connecting rods. 3 two spray racks connected together, each of the connecting rods is connected to the horizontal driving device 4 of the spray rack, and a set of spray pipes 5 are installed on each of the spray racks, and the spray pipes A water supply pipeline 7 is connected through a solenoid valve 6 , and the solenoid valve and the horizontal drive device are connected to a continuous casting machine control system 8 . The spray pipes described in this embodiment are connected together through the water supply main pipe, and the solenoid valve is installed on the water supply main pipe.

[0027] In the micro-alloy steel continuous casting slab corner vertical bending section forced c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com