Plastic optical fiber laser-welding technique and application thereof

A plastic optical fiber and laser welding technology, applied in laser welding equipment, welding equipment, manufacturing tools, etc., can solve problems such as difficult quality assurance, low production efficiency, and high labor intensity, and achieve small vibration stress and thermal stress and slow down aging Speed, less resin degradation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

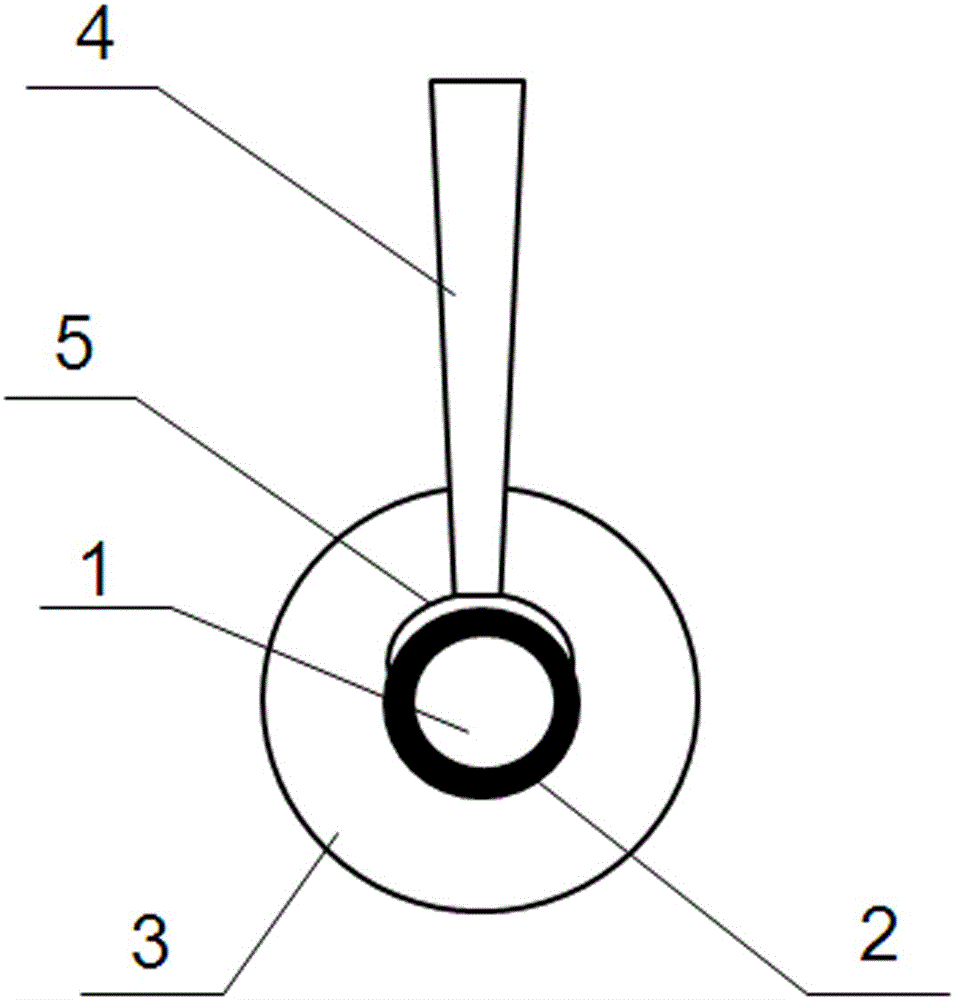

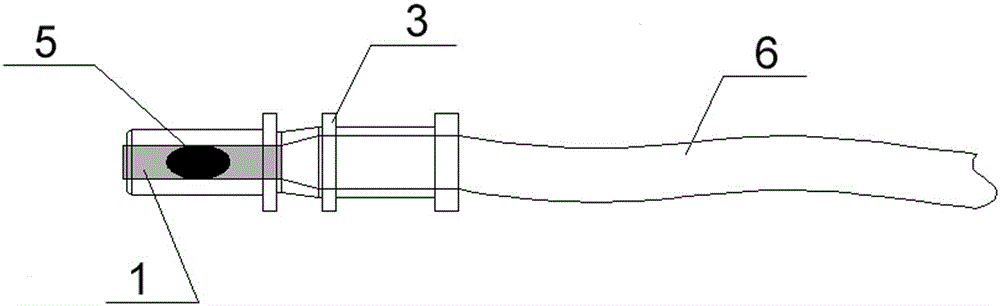

[0025] Such as figure 1 and 2 Shown, the plastic optical fiber laser welding process of the present invention is:

[0026] 1. Install the plastic ferrule (3) on the inner sheath (2) outside the plastic optical fiber core (1) at one end of the plastic optical fiber (6) to be welded;

[0027] 2. The semiconductor laser emits near-infrared laser light (4) passing through the plastic ferrule (3);

[0028] 3. The laser light (4) is absorbed by the inner sheath (2) of the plastic optical fiber (6);

[0029] 4. The inner sheath (2) converts light energy into heat energy and melts the contact surface of the inner sheath (2);

[0030] 5. Heat energy is simultaneously transmitted to the inner surface of the plastic ferrule (3) that transmits the near-infrared laser, forming a melting zone, and the melting zone produces intermolecular mixing;

[0031] 6. A welding seam is formed at the welding surface (5) during the rapid cooling process.

Embodiment 2

[0033] Such as figure 1 and 2 As shown, the wavelength of the near-infrared laser (4) used in the present invention is 940nm.

[0034] The technical parameters of the laser welding process of the present invention are: energy density ED=0.364J / mm 2 , Welding power P=40W, the power is 40W, the beam transmission mode is optical fiber, and the welding speed is 40mm / s.

[0035] The above plastic optical fiber inner sheath (2) is made of PA12 plastic containing carbon black, and the plastic ferrule (3) is made of transparent PA12 plastic.

[0036] This process uses a semiconductor laser welding process to weld the plastic ferrule to the inner sheath of the plastic optical fiber. Laser welding can produce precise, strong and sealed welds, and there is less resin degradation, less debris, and no pollution due to the non-contact nature of the laser. Another advantage is that laser welding produces less vibration than other joining methods. The stress and thermal stress are small, ...

Embodiment 3

[0038] Such as figure 1 and 2 As shown, the wavelength of the near-infrared laser (4) used in the present invention is 810nm.

[0039] The technical parameters of the laser welding process of the present invention are: energy density ED=0.351J / mm 2 , welding power P=20W, beam transmission mode is optical fiber, welding speed is 5mm / s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com