High-gamut light diffuser and production process thereof

A light diffusion sheet and high color gamut technology, which is applied in optics, optical components, instruments, etc., can solve the problems of low color gamut and poor color reproduction of LED backlights, and achieve improved color gamut, improved purity, and reduced effect of thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

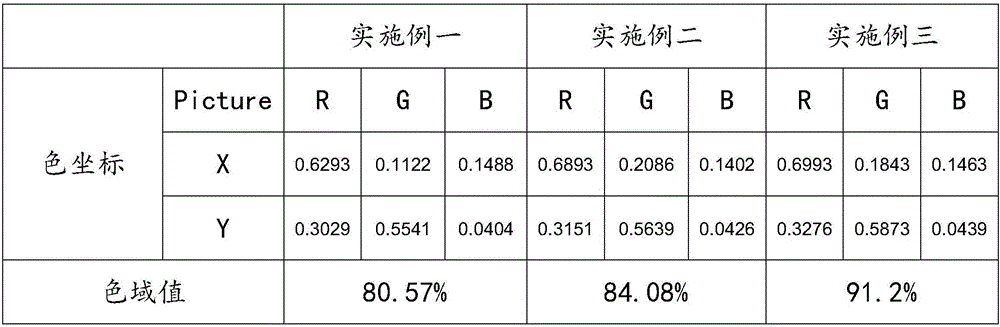

Embodiment 1

[0032] A high color gamut light diffusion sheet, the composition and parts by weight of the light diffusion sheet are:

[0033] 99 raw materials

[0034] 1 part of optical masterbatch;

[0035] The material includes one or a mixture of light-transmitting PP plastic particles, PC plastic particles, PMMA plastic particles, ABS plastic particles, PS plastic particles, and MS plastic particles;

[0036] Described optical master batch comprises the mixture of 0.5 part of red optical master batch and 0.5 part of green optical master batch; The composition and parts by weight of described red optical master batch are:

[0037] 97 raw materials

[0038] 0.1 part of lubricating dispersant

[0039] 1 part of red fluorescent powder

[0040] 1 part silicone microsphere;

[0041] The composition and parts by weight of the green optical masterbatch are:

[0042] 97 raw materials

[0043] 0.1 part of lubricating dispersant

[0044] 1 part green fluorescent powder

[0045] 25 parts o...

Embodiment 2

[0054] The main steps and processes of this embodiment are the same as those in Embodiment 1, and will not be repeated here. The difference lies in the corresponding proportion of components: 15 parts of optical masterbatch, including 7.5 parts of red optical masterbatch and 7.5 parts of green optical masterbatch The mixture; wherein, the composition and parts by weight of red optical masterbatch are: 81 parts of this material, 0.5 part of lubricating dispersant, 5 parts of red fluorescent powder, 12.5 parts of organosilicon microspheres; The composition and parts by weight of green optical masterbatch are : 81 parts of raw materials, 0.5 parts of lubricating and dispersing agent, 5 parts of green fluorescent powder, 12.5 parts of silicone microspheres.

[0055] Select 85 parts of raw materials by weight ratio, select 7.5 parts of green optical masterbatch and 7.5 parts of red optical masterbatch, stir and mix evenly and put them into an extrusion molding machine, and form a di...

Embodiment 3

[0060] The main steps and processes of this embodiment are the same as those of Embodiment 1, and will not be repeated here. The difference lies in the selection and corresponding proportions of the components:

[0061] 30 parts of optical masterbatch, which contains a mixture of 15 parts of red optical masterbatch and 15 parts of green optical masterbatch; wherein, the composition and weight parts of red optical masterbatch are: 66 parts of this material, 0.9 parts of lubricating and dispersing agent, red fluorescent 9 parts of powder, 25 parts of silicone microspheres; the composition and parts by weight of the green optical masterbatch are: 66 parts of this material, 0.9 parts of lubricating dispersant, 25 parts of green fluorescent powder, and 25 parts of silicone microspheres.

[0062] Select 70 parts of raw materials by weight ratio, select 15 parts of green optical masterbatch and 15 parts of red optical masterbatch, stir and mix evenly and put them into an extrusion mol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com