Transparent antistatic electronic tape carrier sheet and its preparation method

An antistatic and electronic technology, applied in the field of transparent antistatic electronic tape carrier sheet and its preparation, can solve the problems of mechanical strength, insufficient transparency and light transmittance, etc., achieve long-term and stable antistatic effect, avoid migration and precipitation, and antistatic The effect is even and

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

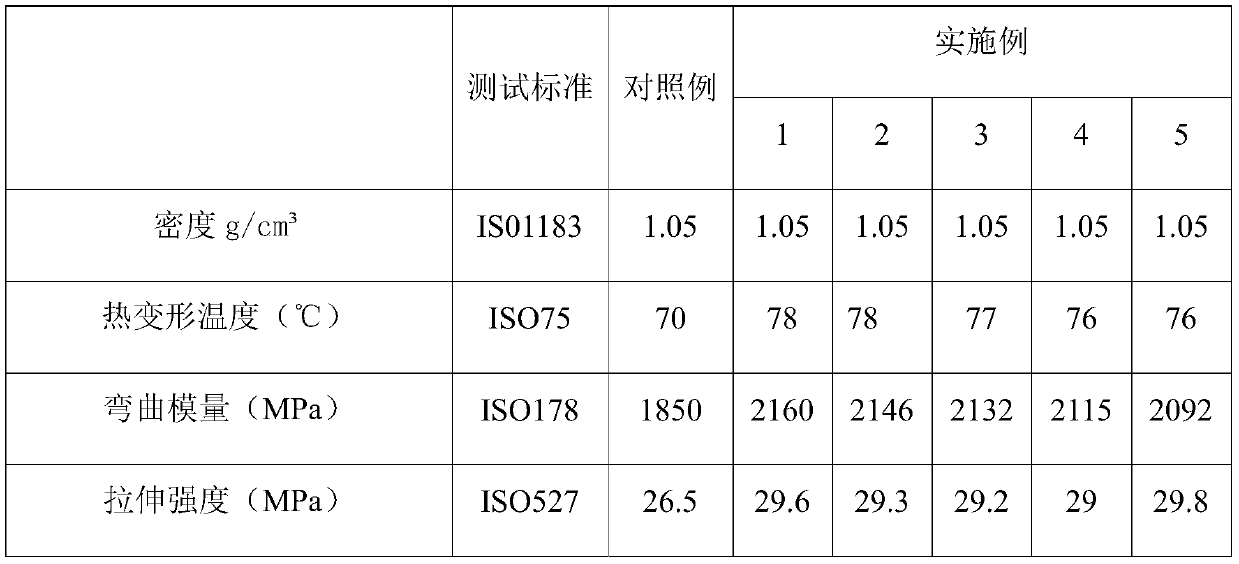

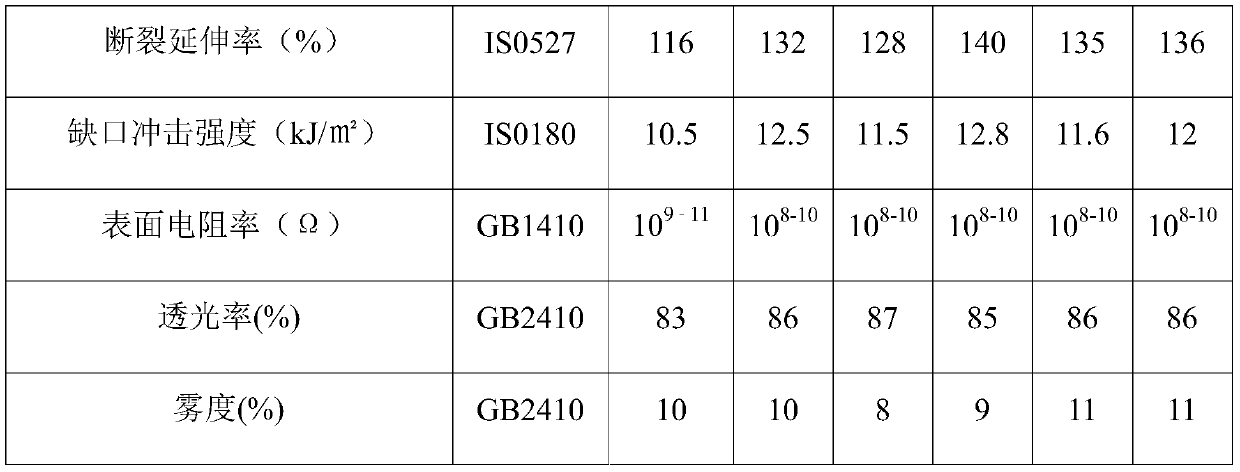

Examples

Embodiment 1

[0023] A transparent antistatic electronic tape carrier sheet is composed of an intermediate layer, an antistatic upper surface layer and an antistatic lower surface layer. During actual preparation, it is obtained through the following procedures:

[0024] 1) Prepare the raw materials, the middle layer is composed of the following mass percentages: GPPS resin (general-purpose polystyrene resin) 56.5%, MBS resin (methyl methacrylate-butadiene-styrene copolymer) 35% , MS resin (methyl methacrylate-styrene copolymer) 8%, ultraviolet absorber 0.3%, antioxidant 0.2%.

[0025] The antistatic upper surface layer and the antistatic lower surface layer have the same components, and are composed of the following components in mass percentages: GPPS resin 63.5%, MBS resin 25%, MS resin 8%, PS antistatic masterbatch 3%, ultraviolet light Light absorbing agent 0.3%, antioxidant 0.2%.

[0026] 2) Granulation, after mixing the ingredients of the middle layer with SHR-300A high-speed mixer,...

Embodiment 2

[0032] Its structure and material selection of the transparent antistatic electronic tape-carrying sheet provided in this embodiment are basically consistent with Embodiment 1, the difference is:

[0033] 1. The middle layer is composed of the following components by mass percentage: 51.5% of GPPS resin, 38% of MBS resin, 10% of MS resin, 0.1% of ultraviolet light absorbing agent, and 0.4% of antioxidant.

[0034] The antistatic upper surface layer and the antistatic lower surface layer have the same components, and are composed of the following components in mass percentages: GPPS resin 53.5%, MBS resin 29%, MS resin 15%, PS antistatic masterbatch 2%, ultraviolet light Light absorbing agent 0.4%, antioxidant 0.1%.

[0035] 3. The thickness of the prepared sheet is 0.4 mm.

Embodiment 3

[0037] Its structure and material selection of the transparent antistatic electronic tape-carrying sheet provided in this embodiment are basically consistent with Embodiment 1, the difference is:

[0038] 1. The middle layer is composed of the following components by mass percentage: 49% of GPPS resin, 45% of MBS resin, 5% of MS resin, 0.5% of ultraviolet light absorbing agent, and 0.5% of antioxidant.

[0039] The antistatic upper surface layer and the antistatic lower surface layer have the same components, and are composed of the following components in mass percentages: GPPS resin 58.5%, MBS resin 30%, MS resin 7%, PS antistatic masterbatch 4%, ultraviolet light Light absorbing agent 0.3%, antioxidant 0.2%.

[0040] 3. The thickness of the prepared sheet is 0.3 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com