Dynamic spinning melt mixer

A dynamic mixer and melt technology, applied in textiles and papermaking, filament forming treatment, fiber treatment, etc., can solve problems affecting melt quality and performance, large melt temperature rise, large temperature rise, etc., to achieve structural Simple, control temperature rise, improve the effect of mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

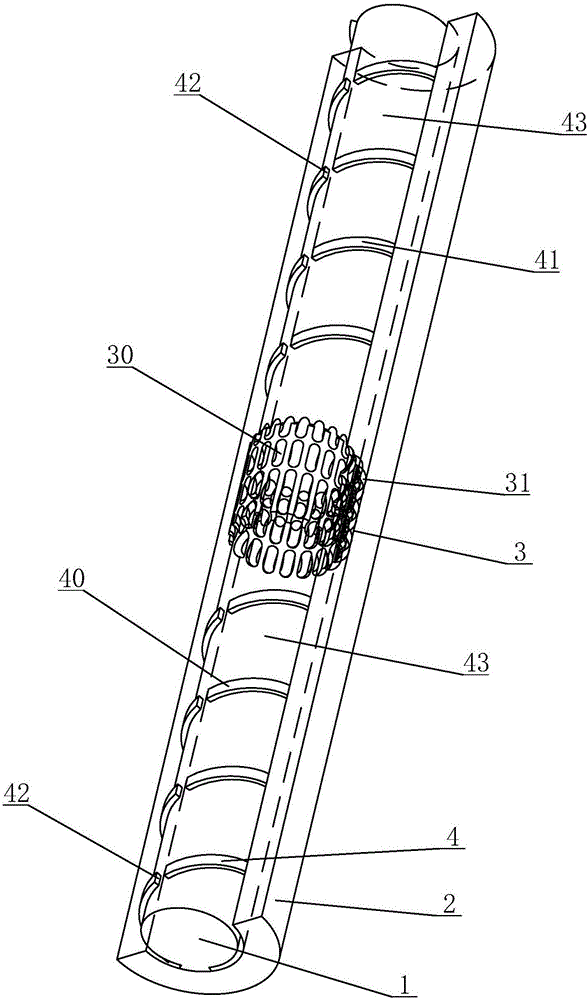

[0018] see figure 1 as shown, figure 1 It is a schematic diagram of the three-dimensional structure of the textile melt dynamic mixer provided in Embodiment 1 of the present invention.

[0019] In this embodiment, a textile melt dynamic mixer includes a mixing shaft 1 and a mixing sleeve 2, the mixing shaft 1 is rotatably arranged in the mixing sleeve 2, and the mixing shaft 1 and the mixing sleeve The middle part of 2 is provided with a mixing section 3 for melt mixing, and the outer wall of the mixing shaft 1 is provided with spiral ribs 4 for melt conveying on both sides of the mixing section 3, advancing along the melt material The spiral rib located in the front section of the mixing section 3 is the input spiral rib 40, and the spiral rib located at the rear section of the mixing section 3 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com