Reactive dye duplex printing method

A technology of reactive dyes and double-sided printing, which is applied in dyeing, textiles, and papermaking. It can solve the problems of mutual interference between the front and back sides, and achieve the effect of strong expressiveness, rich layering, and bright colors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

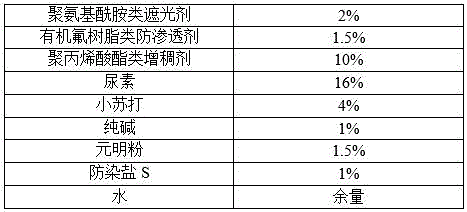

[0028] First, prepare the pretreatment working solution according to the following formula.

[0029]

[0030] Secondly, the pure cotton fabric is uniformly padded, padded with the pretreatment working solution, and the pretreatment solution is evenly applied to the front and back sides, the fabric carrying rate is 70%, and dried at 105°C.

[0031] Then, the front of the pure cotton fabric is ink-jet printed with reactive dye ink, and after drying at 105°C, the reverse side of the fabric is ink-jet printed with reactive dye ink, and dried at 105°C.

[0032] Finally, steam with saturated steam for 7 minutes at 102°C, wash with water, dry, and tenter.

[0033] The analysis of the double-sided printed fabric samples of pure cotton fabric shows that the front and back patterns of the fabric do not affect each other, and have high fineness, bright color, strong expressiveness, rich layering, soft hand feeling and good fastness. This fully demonstrates that the present invention ...

Embodiment 2

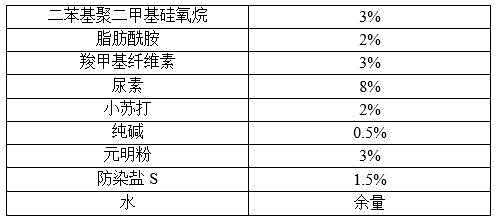

[0035] First, prepare the pretreatment working solution according to the following formula.

[0036]

[0037] Secondly, the Tencel fabric is evenly rolled, one dipped and one rolled, and the pretreatment working solution is applied to the front and back sides of the padding.

[0038] Then, ink-jet printing is carried out with reactive dye ink on the front of the fabric, and after drying at 90° C., ink-jet printing is carried out with reactive dye ink on the reverse side of the fabric, and dried at 90° C.

[0039] Finally, steam with saturated steam at 102°C for 14 minutes, wash with water, dry, and tenter.

[0040] The analysis of the double-sided printed fabric samples of Tencel fabric shows that there is a sheath and core layer in the Tencel fabric, which is quite different from the pure cotton fabric, and the formula composition of the pretreatment working solution needs to be adjusted. The front and back patterns of Tencel fabric do not affect each other, and have high...

Embodiment 3

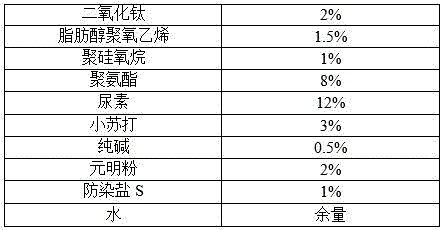

[0042] First, prepare the pretreatment working solution according to the following formula.

[0043]

[0044] Secondly, the silk fabric is uniformly padded, one dipped and one rolled, and the pretreatment working solution is applied to both sides of the front and back of the padding.

[0045] Then, the front of the fabric is ink-jet printed with reactive dye ink, and after drying at 85°C, the reverse side of the fabric is ink-jet printed with reactive dye ink, and dried at 85°C.

[0046] Finally, steam with saturated steam for 7 minutes at 102°C, wash with water, dry, and tenter.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com