Small-tonnage hydraulic elevator for repairing well

A small-tonnage, hydraulic technology, applied in the field of elevators, can solve the problems of being unable to adapt to automatic workover drilling rigs, cumbersome hydraulic elevators, and heavy hydraulic elevators, so as to avoid wellhead safety accidents, save manpower, and lower maintenance costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

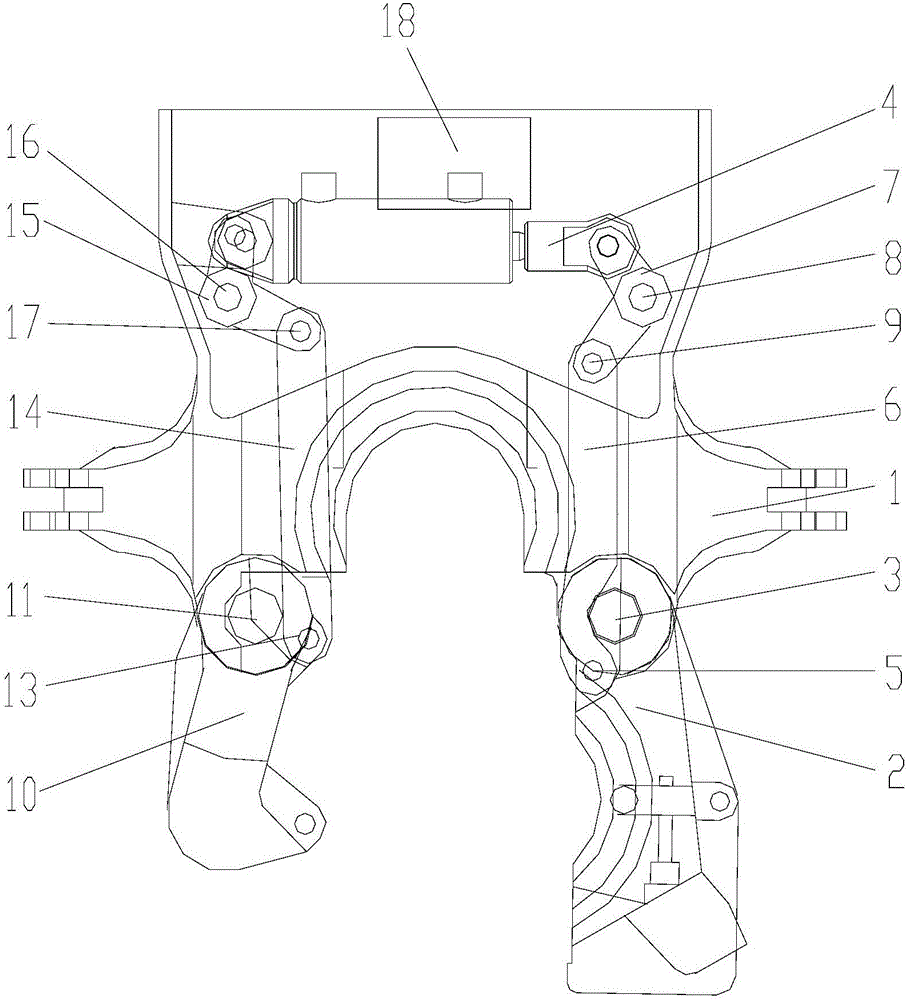

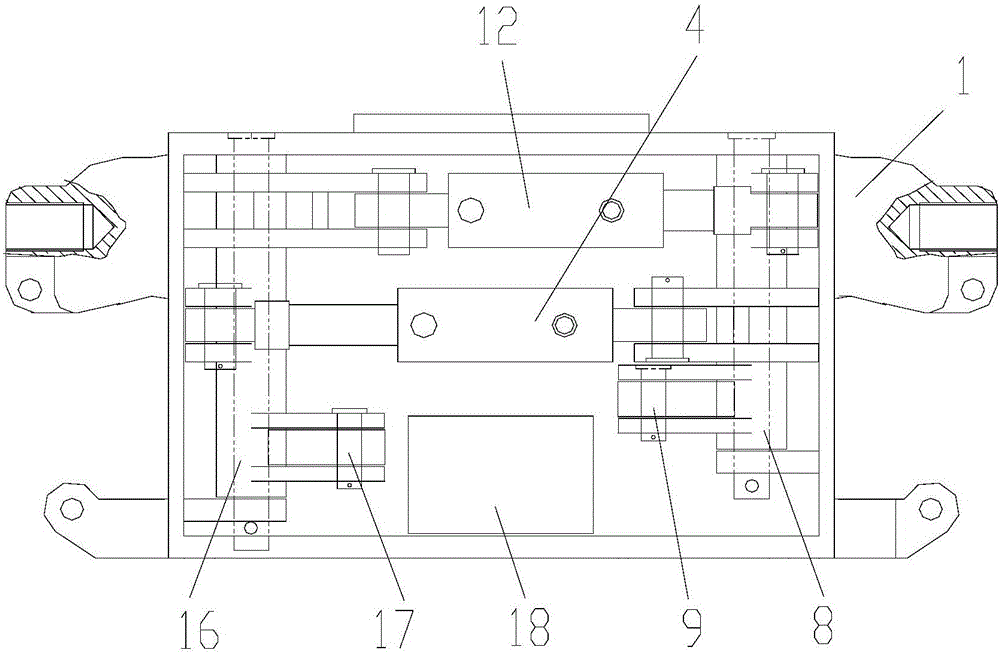

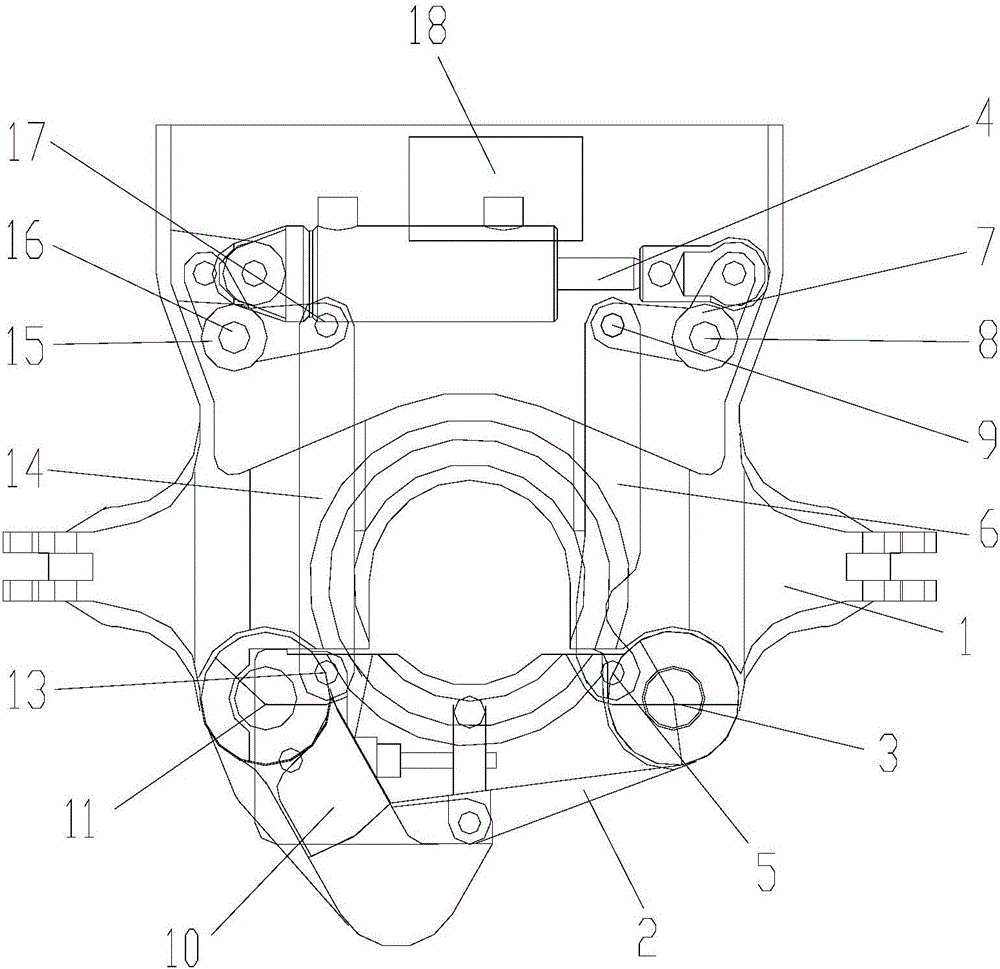

[0015] Attached below Figure 1-3 Embodiments of the present invention are described.

[0016] Small tonnage hydraulic elevators for well workover, such as figure 1 and 2 As shown, it has a main body 1, a valve 2 and a deadbolt 10. The valve 2 is connected to one side of the lower part of the middle hole of the main body 1 through the valve shaft 3, and the dead bolt 10 is connected to the lower part of the middle hole of the main body 1 through the dead bolt shaft 11. One side swivel connection.

[0017] The upper side of the main body 1 is provided with a valve cylinder 4, the piston rod of the valve cylinder 4 is hinged with the valve 2 through the valve linkage mechanism and drives the valve 2 to rotate around the valve shaft 3; specifically, the valve linkage mechanism Including the valve connecting rod pin 5, the valve connecting rod 6 and the valve crank arm 7, the middle of the valve crank arm 7 is fixed on the main body 1 through the valve crank arm hinge pin 8, on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com