On-off control method for electric braking air compressor system by improving combined dryer

An electric braking and combined drying technology, applied in machine/engine, pump control, mechanical equipment, etc., can solve the problem of asynchronous start-stop control dryer unloading and purging action, and air compressor start-stop dryer unloading action Out of synchronization, reducing the reliability and life of the braking system, etc., to achieve the effect of easy implementation, reliable performance and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

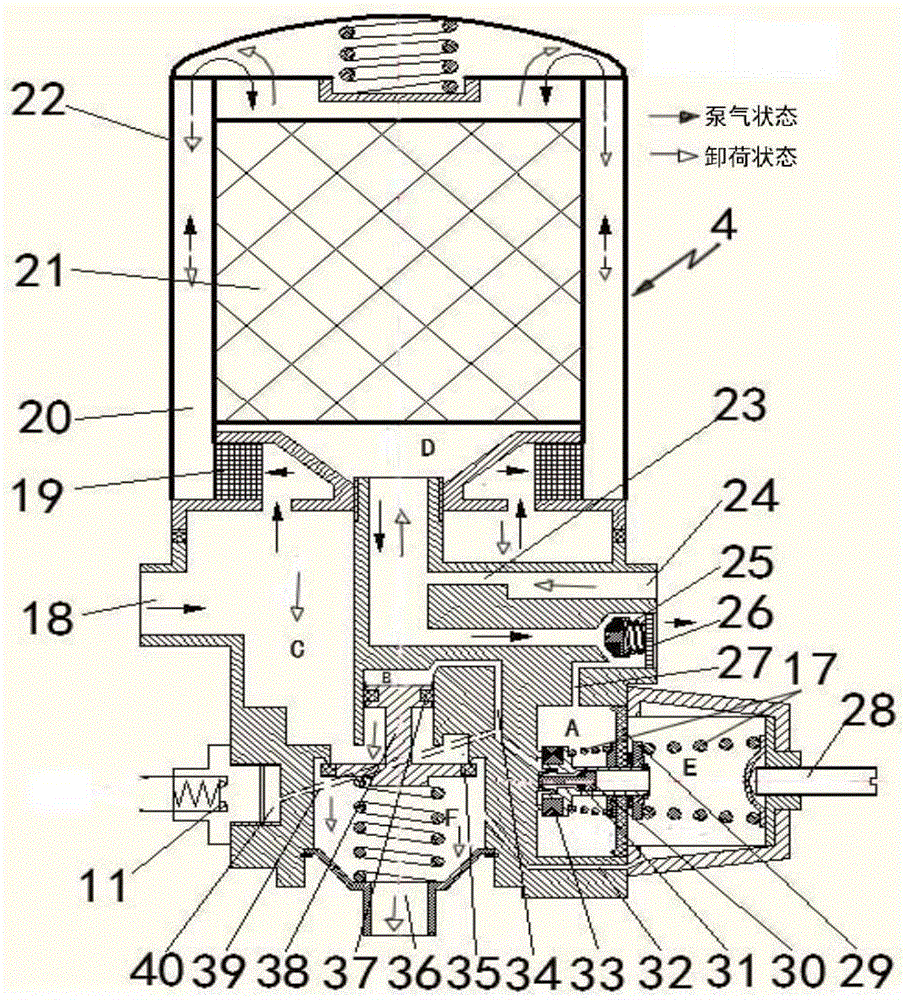

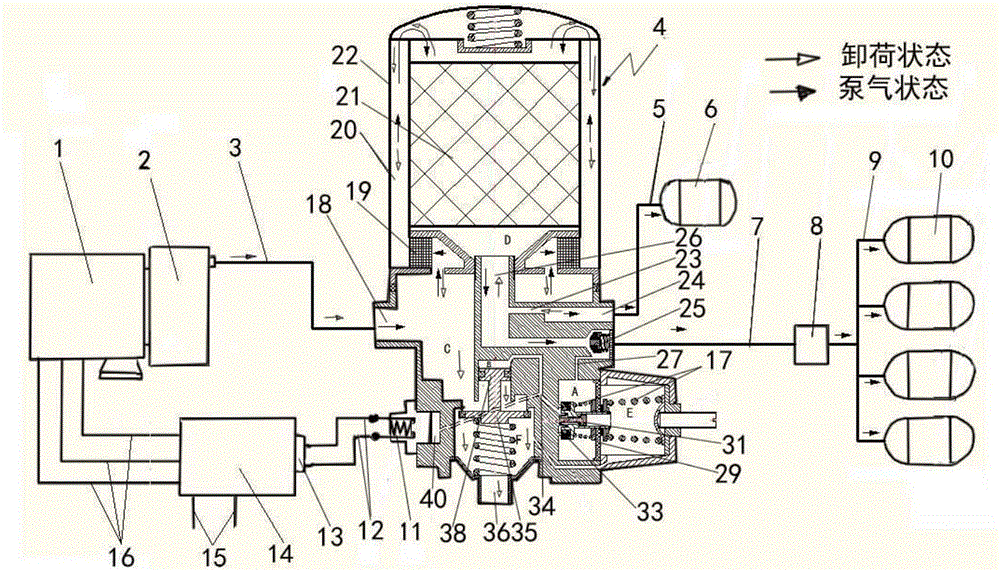

[0015] The present invention proposes a start-stop control method of an electric brake air compressor system using an improved combined dryer, which will be described below in conjunction with the accompanying drawings.

[0016] like figure 1 The schematic diagram of the structure and control principle of the electric brake air compressor system using the improved combined dryer is shown; the solid arrow in the figure indicates the pumping state; the hollow arrow indicates the unloading state. The electric brake air compressor system with improved combined dryer shown in the figure is composed of electric brake air compressor, inverter, improved combined dryer, regenerative air storage tank, four-circuit protection valve and air storage tank; The air compressor driving motor 1 and the air compressor 2 are combined into an electric brake air compressor, and the air compressor 2 is connected to the improved combined dryer 4 through the air compressor air pipe 3, and the improved...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com