Method for testing PCB adhesive removing uniformity

A technology of PCB board and test method, applied in the field of testing the uniformity of degumming of PCB board, can solve the problems of excessive degumming, insufficient degumming of through holes, affecting product quality, etc. The effect of strong promotion meaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the technical solution of the present invention more clearly expressed, the present invention will be further described below in conjunction with the accompanying drawings.

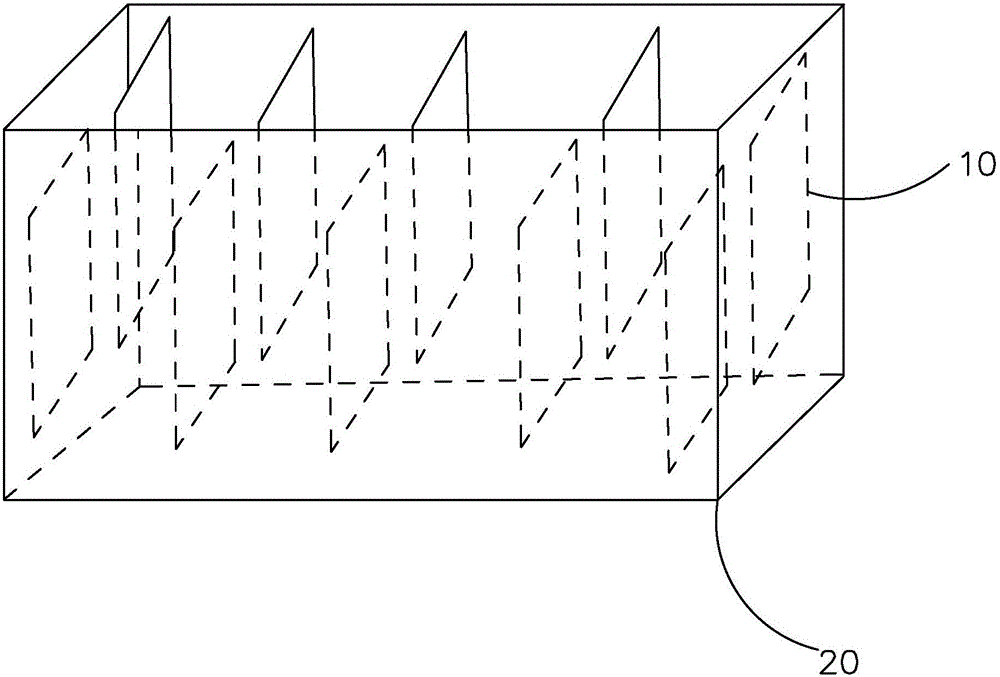

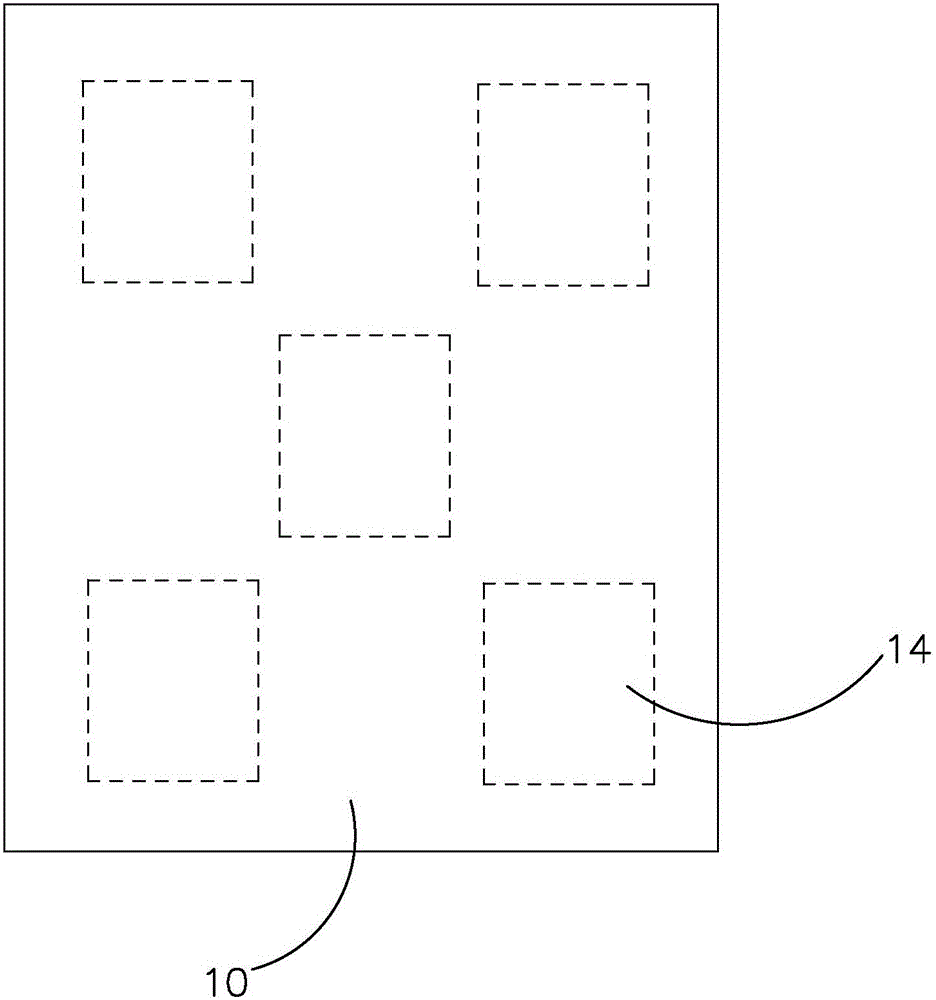

[0016] Such as Figure 1 to Figure 4 As shown, the present invention provides a method for testing the uniformity of glue removal of PCB boards, which is used to test the uniformity of glue removal of PCB boards, and it may further comprise the steps:

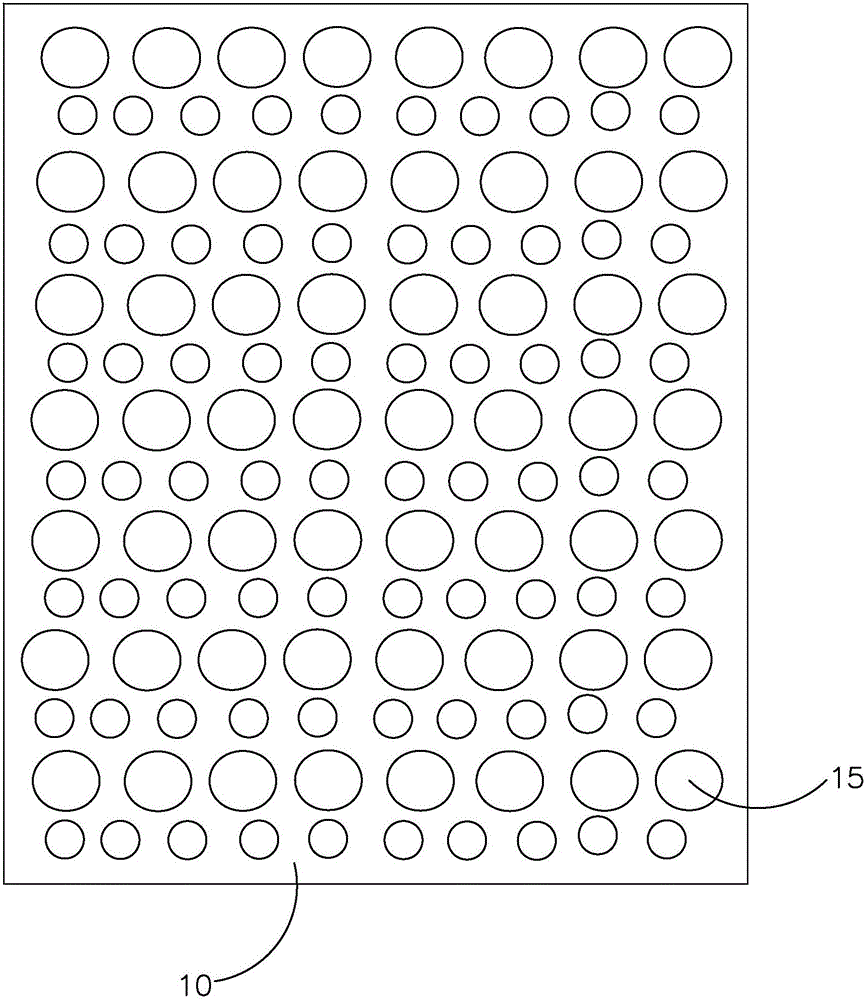

[0017] (1), provide a group of test boards 10, obtain the weight information and the image information of each test board 10, this test board 10 includes some PP11 stacked in layers, the inner layer copper 12 sandwiched between the two PP11, the device On the two outer layers of copper 13 on the upper and lower outermost surfaces, each test board 10 is divided into several test areas 14, and the 10 areas of the test board are provided with a number of through holes 15 of different specifications, and the through holes 15 run through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com