Electronic product frame structure made of carbon fiber ceramic composite material and manufacturing method of the structure

A technology of ceramic composite materials and electronic products, which is applied in the direction of telephone structure, telephone communication, electrical components, etc., can solve the problems of difficult mechanical processing, difficult assembly, and difficult to achieve precise assembly, and achieves carbon fiber light weight and easy post-processing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Embodiments of the present invention will be described in detail below. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

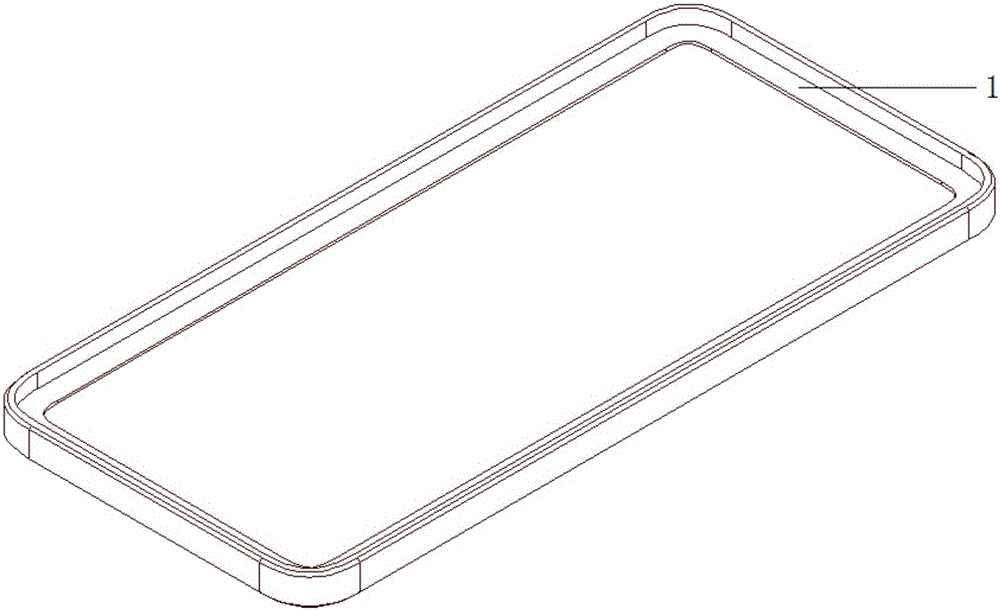

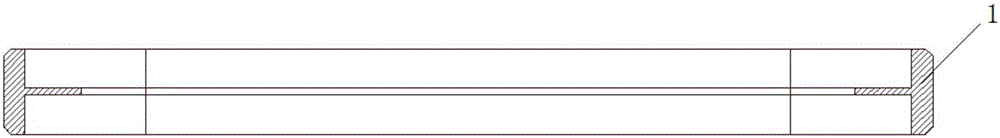

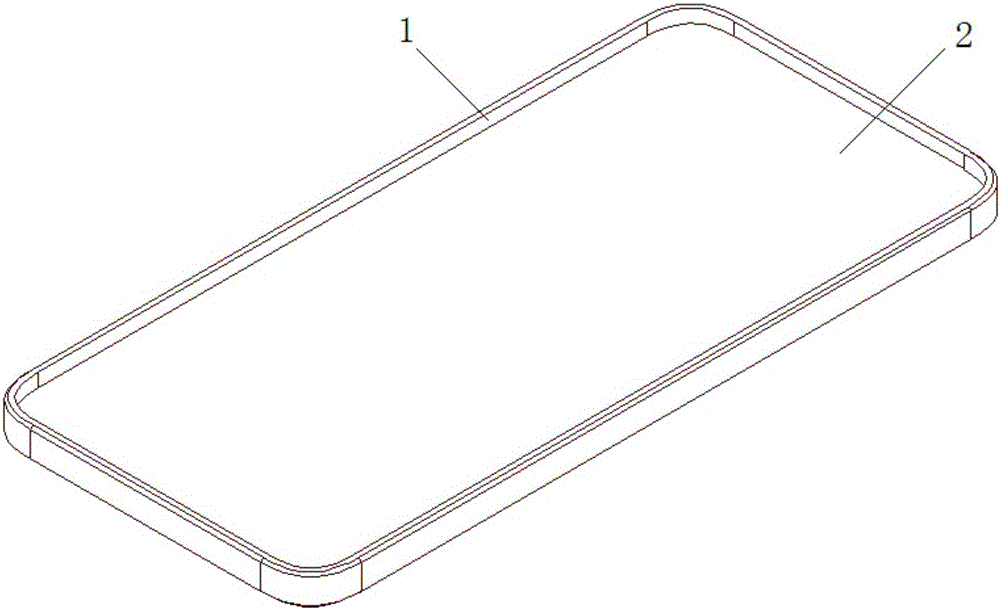

[0029] refer to Figure 1a to Figure 3 , in one embodiment, a carbon fiber ceramic composite electronic product frame structure, including a ceramic frame 1 and a carbon fiber middle frame plate 2 located inside the ceramic frame 1 and integrally composited with the ceramic frame 1, The carbon fiber middle frame plate 2 is integrally formed with the ceramic frame 1 through hot pressing and curing. Typically, the frame structure of the electronic product may be (but not limited to) the frame structure of a mobile phone.

[0030] In a preferred embodiment, the carbon fiber middle frame plate 2 is a carbon fiber structure formed by 3D molding and hot-pressing curing of carbon fiber cloth stacked interlaced on the inside of the ceramic frame 1 .

[0031]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com